Magazine Articles

Next Gen Automation

In this feature for Cutting Tool Engineering magazine, Absolute Machine Tools’ Jeff Bennett discusses how automation is helping manufacturers who struggle to find and retain employees mundane, repetitive tasks.

Publication: Cutting Tool Engineering

Published: May 1, 2025

Productivity in the Palmetto State

Screwmatics of South Carolina revitalized its automation efforts with the help of Absolute Machine Tools. After initial struggles with robotic integration, Screwmatics turned to Absolute and their Productive Robotics’ OB7 cobots. Absolute’s technicians provided the support and training necessary to ensure a smooth installation and operation, leading to significant productivity gains for Screwmatics. Their collaborative robots now outperform human workers, and the partnership with Absolute has been key to their success.

Publication: SME Media

Published: Aug 1, 2024

Rigidity Reigns Supreme for Utilities Drilling OEM

Barbco, a well-known producer of trenchless boring equipment for the underground construction industry, made the switch from 5 axis to a Johnford bridge mill with help from Absolute Machine Tools.

Publication: Modern Machine Shop

Published: April 1, 2024

New On-Ramps to Workforce Development

Absolute Machine Tools’ apprenticeship program is featured in this April 2024 article in Manufacturing Engineering magazine. “We try to bring in students during their junior year of high school, working with them a few days during the week and then full time during summer vacation,” Dave Zunis, Absolute’s director of applications engineering and service, explains in the article. “By the time they graduate, they have a pretty good handle on what we do here, and assuming they like it and have the aptitude, we’ll hire them on as apprentices.”

Publication: Manufacturing Engineering

Published: April 1, 2024

OEM Moves From Five-Axis to Three-Axis for Improved Rigidity

After experiencing rigidity issues with a five-axis machine, Barbco moved its large parts to a double-column Johnford DMC-4100PH three-axis mill from Absolute Machine Tools. The Johnford is able to handle both heavy-duty roughing and fine-tolerance work, a feature crucial for Barbco’s production of durable parts for high-wear industries. The change has also allowed Barbco to design more complex parts and maintain flexibility in production, even when handling rush orders.

Publication: Modern Machine Shop

Published: January 1, 2024

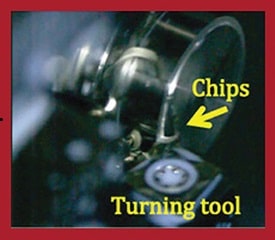

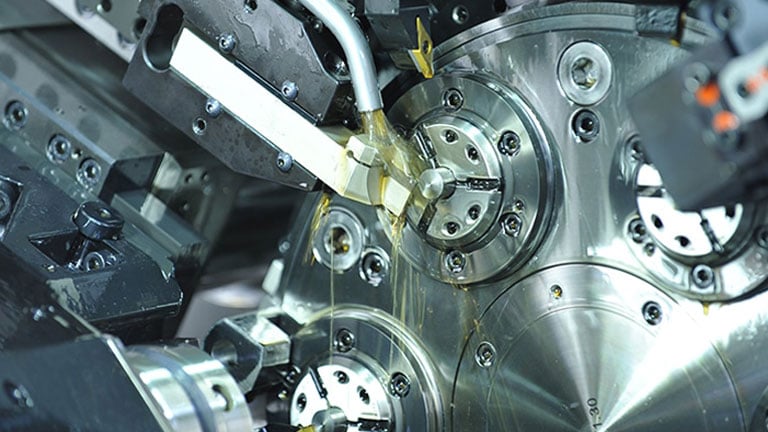

CNC Turning Technology Targets Its Many Facets

David Zunis, director of service and applications engineering, Absolute Machine Tools, discusses overcoming the challenges of chip breakage in turning operations involving exotic materials, stainless steels and those with high nickel content.

Publication: SME Media

Published: September 20, 2023

Unfolding Swiss Style Machines Advances

Jason Smith, national sales manager of production turning products for Absolute Machine Tools Inc., explains how advancements in Swiss machines have made it it is easier to train users and reduced the cost of assembly and resulted in fewer “errors in the field.”

Publication: SME Media

Published: July 12, 2023

Automation: Today and Beyond

Courtney Ortner, chief marketing officer for Absolute Machine Tools Inc., shares her insights into the future of automation in manufacturing and the reluctance of many shops to begin integrating automation into their operations.

Publication: SME Media

Published: April 21, 2023

‘It’s a Wonderful Life’ Working with Precision Turned Parts

Upon his retirement, Greg Knight reflects on his cherished relationships as well as the challenges he has faced during his career in manufacturing.

Publication: Production Machining magazine

Published: November 10, 2022

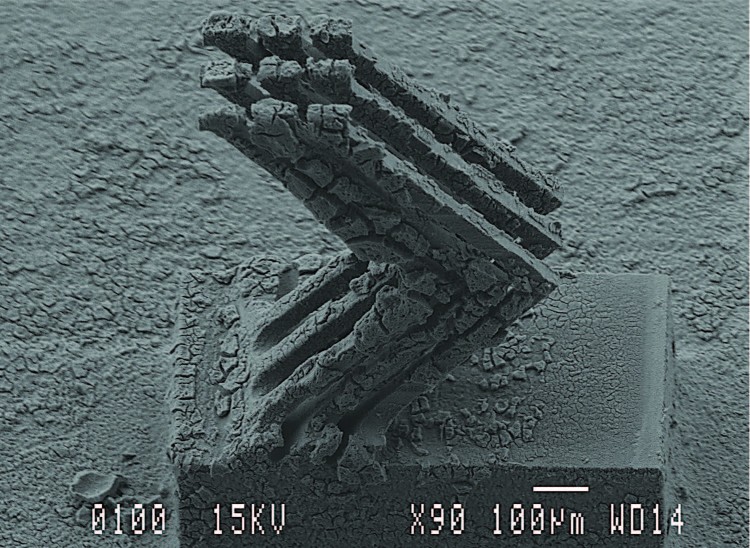

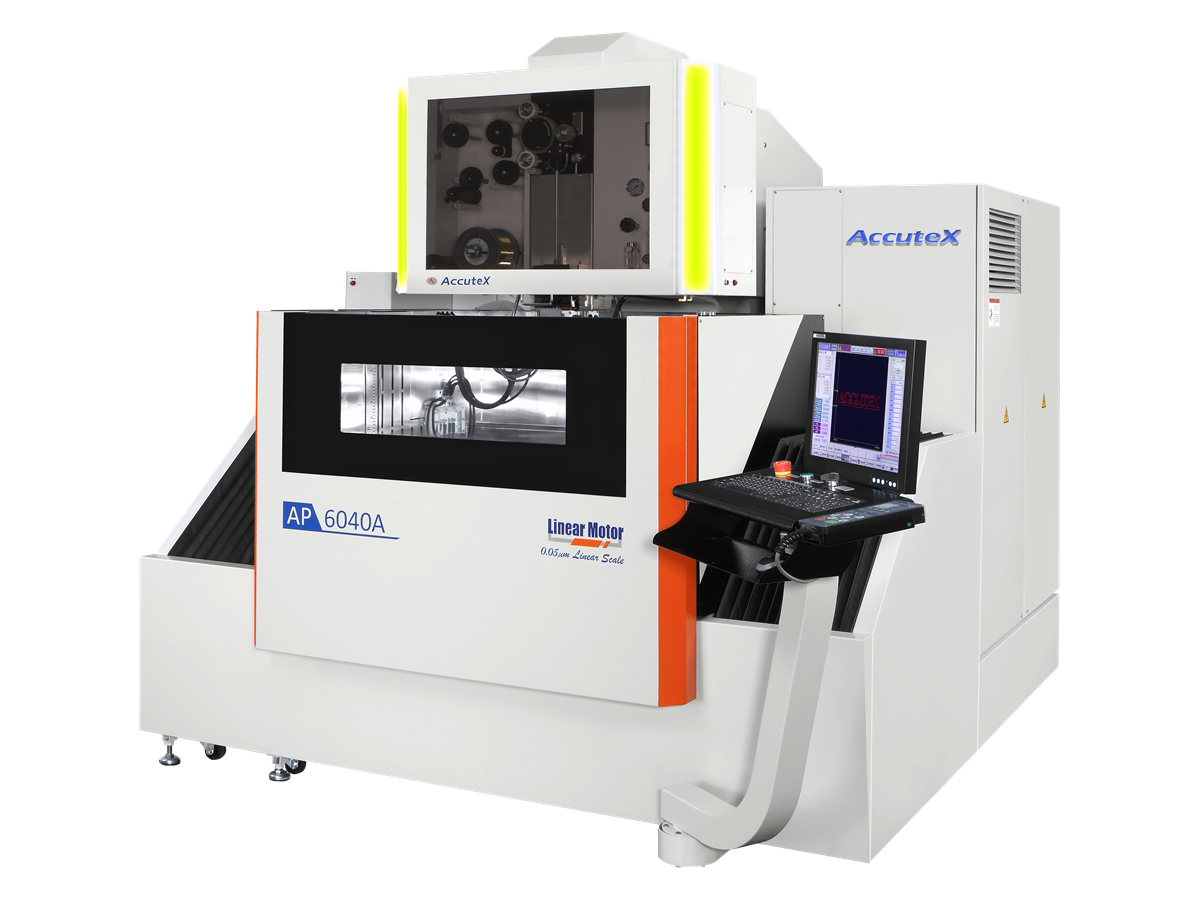

Thinking Outside the EDM Box

Mark Cicchetti, technical director for the EDM division at Absolute Machine Tools Inc., talks about the widening range of applications for =electrical discharge machining and the growing need for fixed-bed EDM machines.

Publication: SME Media

Published: October 27, 2022

Navigating High-Mix, Low-Volume Manufacturing

Applications Engineer Jason Lutch discusses the importance of programming in high-mix, low-volume manufacturing.

Publication: SME.org

Published: July 27, 2022

Swiss-Type Turning Point

Hashier Machine recently added its first Swiss-type lathe to gain long stretches of unattended machining largely because its continuous efforts to find new operators for its more conventional equipment had proven to be unfruitful.

Publication: Production Machining magazine

Published: July 5, 2022

When Work Cells Work for Machine Tools

Courtney Ortner and Dave Zunis of Absolute Machine Tools recently discussed calculating ROI for a collaborative robot in an SME Media article, “When Work Cells Work for Machine Tools.”

Publication: SME Media

Published: May 20, 2022

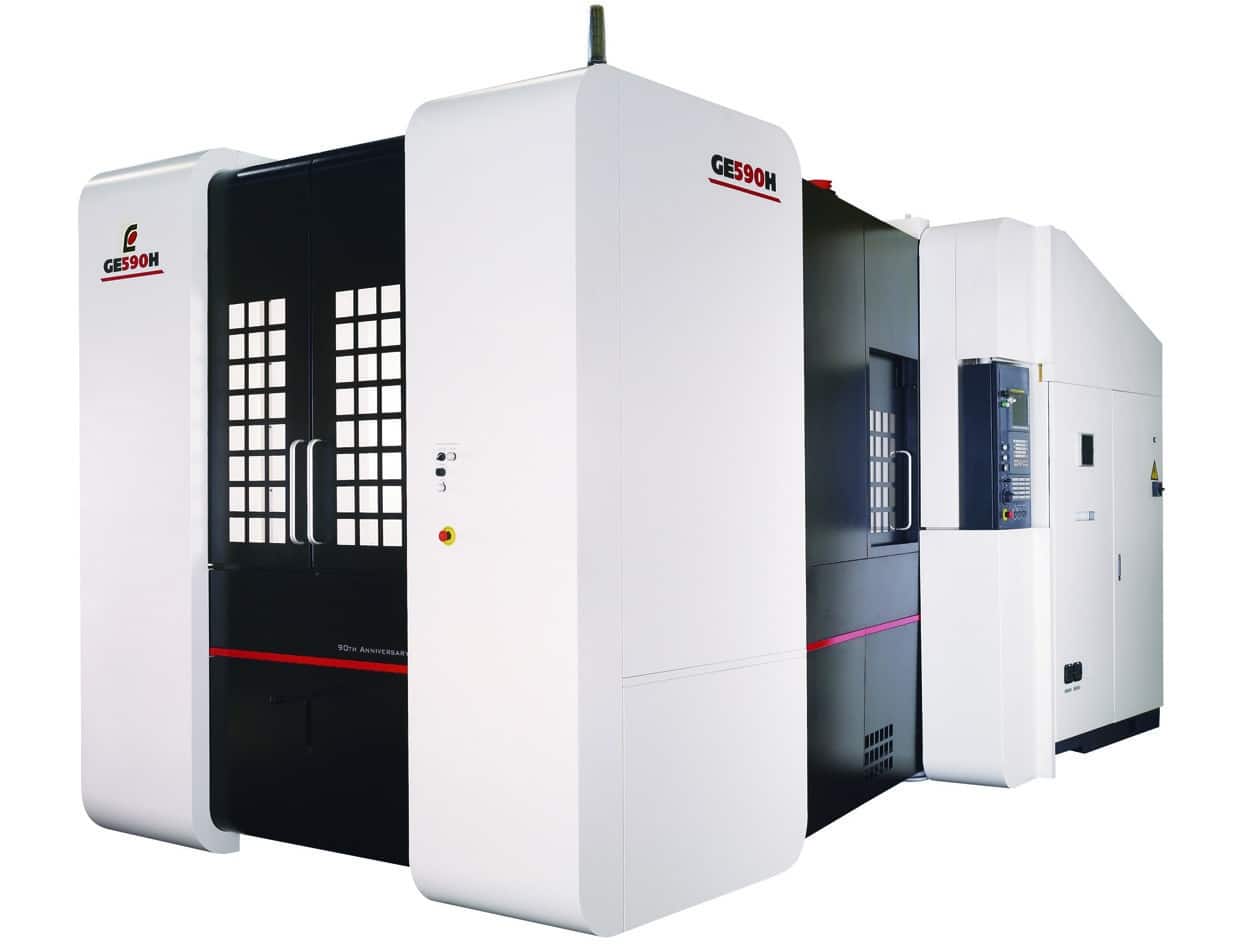

MRO for HRCs: When to Maintain, Rebuild or Replace Horizontal Machining Centers

Klaus Miller, vice president of sales at Absolute Machine Tools Inc., explains why many customers are replacing 15 to 20 year old horizontal machining centers that are worn out and operating significantly slower than modern machines.

Publication: SME Media

Published: February 9, 2022

Automation Solution with Robotic Gripper and Pneumatic Vise

Kurt Workholding and Absolute Machine Tools have teamed up to create an easy and smart way to introduce turn-key automation to a shop. The exclusive package features a Mitsubishi LoadMate Plus, Kurt 3600A Pneumatic Vise and Kurt RV36 Robotic Gripper working in tandem with a Tongtai VP-10 mass-production high-speed vertical machining center (VMC).

Publication: Manufacturing News

Published: December 1, 2021

A New World for Energy Parts Manufacturing

SME Media article, “A New World for Energy Parts Manufacturing,” features insight from Klaus Miller, Absolute Machine Tools’ vice president of sales, on manufacturing for the energy and aerospace industries.

Publication: SME Media

Published: November 30, 2021

Swiss-Style Machining Simplified

Greg Knight and Scott Petrisko of Absolute Machine Tools shared their thoughts on Swiss-style machining in an article featured in SME’s Manufacturing Technology Series 2021 Industry Report.

Publication: SME Media

Published: October 1, 2021

Cobots: Start Simple, Then Add Complexity

Cobots are an ideal, entry-level robotic device for smaller shops to begin using automation in an economical way. Of course, as with any equipment integration, it takes a knowledgeable team with experience to make cobot integration as seamless and painless as possible.

Publication: Manufacturing Engineering

Published: September 1, 2021

Absolute Machine Tools Earns Diamond Partner Status

Absolute Machine Tools, Inc. recently earned the title of Diamond Partner Systems Integrator from Mitsubishi Electric Automation, Inc., an affiliate of the global manufacturer Mitsubishi Electric that focuses on production solutions. The partnership is expected to expand opportunities and bring value to both companies.

Publication: Manufacturing News

Published: April 1, 2024

Production Turning to CNC

Greg Knight, Absolute Machine Tools’ VP of Sales Production Turning Products, recently discussed the evolution of the precision production turning industry in an article in Production Machining magazine titled “Production Turning to CNC.”

Publication: Production Machining Magazine

Published: August 3, 2021

Bridge Mills: A Bridge to Success

Absolute Machine Tools’ vice president of sales, Klaus Miller, recently shared insights in Advanced Manufacturing article “Bridge Mills: A Bridge to Success” on the benefits of bridge mills versus C-frame vertical machining centers.

Publication: Advanced Manufacturing

Published: July 20, 2021

Swiss-Style Machines Simplified

Greg Knight, Absolute Machine Tools’ vice president of sales for production turning products, highlights the importance of a capable CAM system in operating Swiss lathes, and Applications Engineer Scott Petrisko emphasizes the critical role of operator training in maximizing the potential of these machines.

Publication: SME Media

Published: May 13, 2021

Job Shop Automates Using Cobot Arm

B.I.C. Precision Machine Company Inc. invested in Productive Robotics’ OB7 collaborative robot arm, which was supplied by Absolute Machine Tools, to automate a repeat contract job that was very labor intensive.

Publication: Better Production

Published: March 17, 2021

Fast Times for Machine Spindles

Max Paulet, business development manager, North America for PCI-SCEMM, which is based in Saint-Etienne, France and Mason, Ohio and partners with Absolute Machine Tools, Lorain, Ohio, discusses why connectivity is important in the advancement of spindle technology.

Publication: SME Media

Published: January 20, 2021

7-Axis Cobot Reduces Operator Fatigue, Bumps Productivity

B.I.C. Precision is a contract shop in Blanchester, OH, and a top tier contract supplier of components for essential industries such as food processing and packaging equipment, railroad transportation, oil and gas, electronics and medical. The company recently installed an OB7 collaborative robot (cobot) servicing a turning center cell.

Publication: Manufacturing News

Published: December 8, 2020

Cuckoo for Swiss Machining

Absolute Machine Tools’ Application Engineer Scott Petrisko highlights the rigidity and precision of Swiss-style lathes, particularly effective for turning long, slender parts with tight tolerances. He notes that the design of Swiss lathes, with tools close to the guide bushing, reduces deflection issues and allows for the machining of small, complex parts, making them ideal for industries like aerospace and medical. Petrisko also points out the size limitations of these machines, generally unsuitable for parts over 203 mm (8 inches) in length.

Publication: Cutting Tool Engineering

Published: September 1, 2020

When a TURN-MILL Doesn’t Turn

AMoManTech, a precision machine shop in Big Sky Country, uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Publication: Production Machining Magazine

Published: July 1, 2020

Advancing Metalcutting Technology

As car manufacturing consolidates with fewer models built on common platforms, and assertive startups address lower-volume, but growing, niches, machine tools have stepped up to address the agility demands of automotive firms seeking the goal of mass customization.

Publication: Autobeat

Published: February 6, 2020

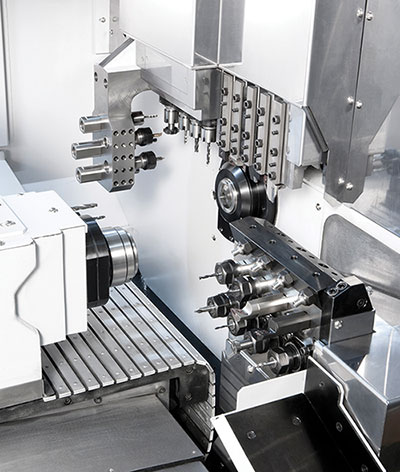

One Spindle, Two Spindles, Three Spindles, More?

There are seemingly endless variations in how milling and turning machines are equipped, including mill-turn and turn-mill combos. But one of the basic ways to differentiate between machine tools is by counting spindles.

Publication: AdvancedManufacturing.org

Published: October 4, 2019

Dual-Spindle Technology a Boon to Automakers

As a key part of auto manufacturing technology, builders are improving machine tools to maximize flexibility and productivity. For example, CNC horizontal machining centers (HMCs) permit multi-sided machining, maximize chip evacuation, and facilitate pallet-based automation systems.

Publication: Manufacturing Engineering Magazine

Published: September 1, 2019

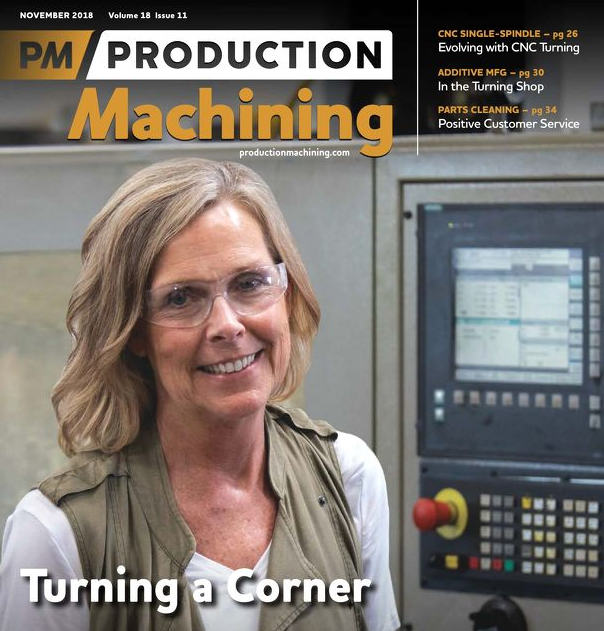

Shop Evolves with CNC Turning

Debbie Sommers answered a newspaper ad for a receptionist job at a South Elgin, Illinois, screw machine shop in 1980. Today, she owns the shop, an 18,000-square-foot facility with 20 employees and sales growth of 25 percent in 2017.

Publication: Production Machining Magazine

Published: November 1, 2018

EDMs Take a Big Step Up To Unattended Eroding

“For the most part, EDMing is an unattended, or at least lightly-attended process. Unlike CNC lathes and machining centers, where a broken cutter during the night can make for a truly bad morning, sinking a mold cavity or cutting a trim die requires little in the way of babysitting—why wouldn’t you let the machine run on its own after everyone’s gone home for the day? If the wire breaks, the EDM will simply thread a new one. If the ‘trode shorts out, the control will do its best to recover or just shut everything down until its human master comes to the rescue. No big deal. Making EDM truly lights-out, however, requires much more than auto-threaders and smart circuitry.”

Publication: Manufacturing Magazine

Published: September 27, 2018

Turning 30 Offers Perspective

In a column for Production Machining Magazine, Absolute Machine Tools president Steve Ortner offers perspective on the company turning 30 year and changes in the machine tool industry in the past three decades.

Publication: Production Machining Magazine

Published:May 20, 2018

The Future Looks Bright for Lights-Out Moldmaking

Steve Ortner, president of Absolute Machine Tools Inc., was recently featured in an article on AdvancedManufacturing.org that gives a fascinating look at the future of untended, or lights-out, machining in mold shops.

Publication: Advanced Manufacturing

Published: May 1, 2018

New Tongtai MT Series Lathes have Twin Spindles and Individual Machining Zones

Tongtai’s newest MT Series Lathes were developed for improving cycle times and turning processes for the automotive industry where small parts are typically made within 60 seconds.

Publication: Machines4Sale.com

Published: October 1, 2016

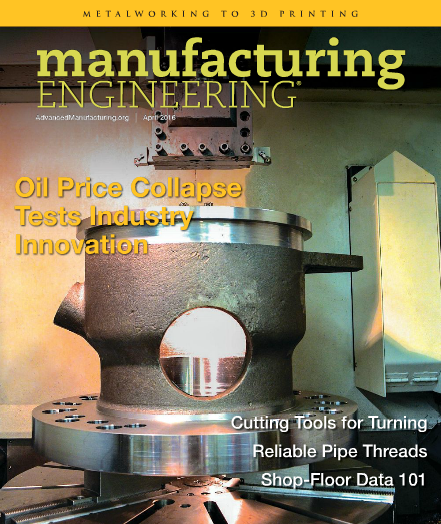

Oil Price Collapse Tests Industry’s Innovation

Steve Ortner, president at Absolute Machine Tools, was part of a feature article in the April edition of Manufacturing Engineering magazine. Ortner contributed to the April 2016 article, “Oil Price Collapse Tests Industry’s Innovation,” a detailed look at changes in the oil and gas industry during the current downturn in crude prices.

Publication: Manufacturing Engineering

Published: April 15, 2016

Big Parts Need Swiss-Type Machines on Steroids

Absolute Machine Tools Chief Marketing Officer Courtney Ortner’s magazine article, “Big Parts Need Swiss-Type Machines on Steroids,” is an insider look at how plummeting crude oil prices are strengthening the relationships between the energy and manufacturing industry.

Publication: Manufacturing Engineering

Published: April 15, 2016