Trepanning

Precihole Trepanning (BTA) Solutions

Trepanning is a special operation used to produce holes or circular grooves by using one or more cutters and revolving them around a center or core, and it’s mainly used when conventional machines are tooled up to do deep hole drilling. Usually in such cases, the machine is less powerful, so BTA drilling is not possible. Trepanning is also used when a solid core is required.

The trepanning operation is performed on a blank workpiece without any holes. The tool geometry allows cutting only on the circular section whereas a solid core is left in the middle, and the core can later be extracted for use.

Typically, only through-hole applications are advisable with trepanning since the core extraction can become troublesome in case of a blind hole. The tool covers a large range of diameters up to 500mm. There are limitations to the lower level of diameter that can be achieved with this process due to the geometry of the tool.

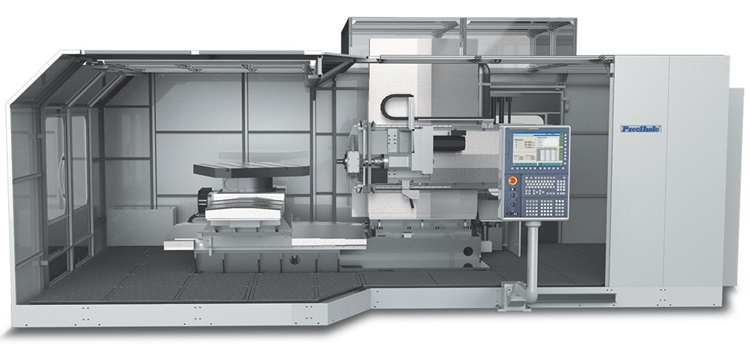

Machines

What Is Trepanning?

Trepanning is a machining process that involves drilling a large-diameter hole into a metal component or structure. The hole produced by trepanning can be circular or non-circular, depending on the shape of the cutting tool used.

During the trepanning process, a specialized cutting tool called a trepan is used. The trepan is a hollow cylinder with teeth on the cutting edge. The trepan attaches to a rotating spindle, which is mounted on a drill press or other machine tooling. The trepan is fed into the workpiece, and the teeth on the cutting edge remove material to create the hole.

What Are the Advantages of Trepanning Over Other Deep Hole Drilling Processes?

A trepanning machine is typically used to produce large-diameter holes in components such as engine blocks, turbine casings, and pipe flanges. It is also used in the aerospace industry to produce holes in aircraft engine components and other structural parts. Trepanning can produce accurate and precise holes with a smooth surface finish, making it ideal for applications where the hole must be leak-tight or have a specific surface finish.

Overall, trepanning is a specialized machining process that is used to produce large-diameter holes with high precision and accuracy.

Other advantages of trepanning include:

Overall, trepanning is a highly efficient and versatile machining process that can produce high-quality, accurate, and precise holes with minimal tool wear and reduced production costs.

ABSOLUTE IS A PROUD SUPPORTING MEMBER OF THE NSSF