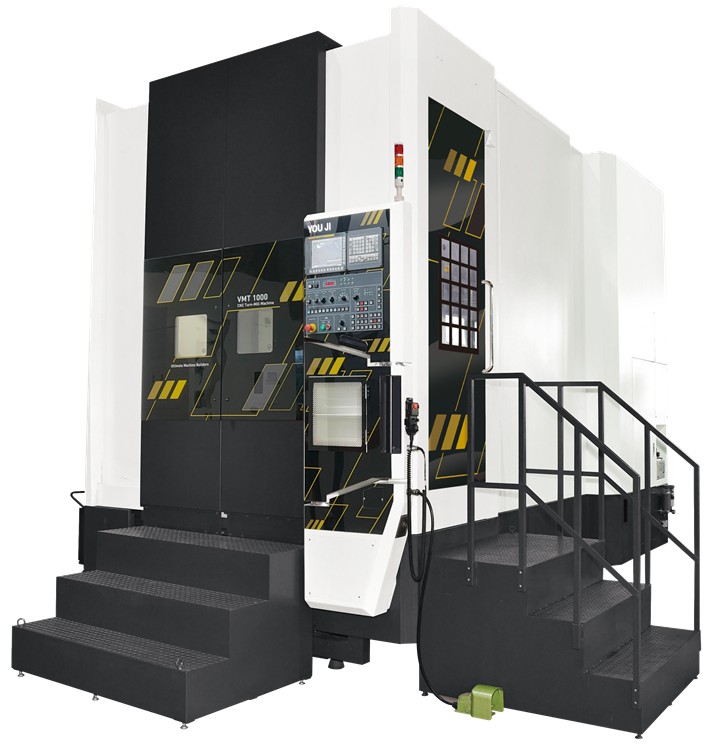

Your Source for CNC Mill Turn Centers

Our CNC mill turn machines offer a multitude of benefits, empowering you to streamline your production and achieve optimal efficiency:

- Versatile Machining Capabilities: With the integration of milling and turning functions, our CNC mill turn machines allow for a wide range of operations, from complex contouring and 3D machining to precision turning and facing. This versatility eliminates the need for multiple setups and machine changes, reducing cycle times and increasing overall productivity.

- Simultaneous Multi-Axis Machining: Our mill turn machines feature advanced multi-axis capabilities, enabling simultaneous machining on multiple sides of the workpiece. This simultaneous operation ensures precise alignment, improved accuracy, and reduced cycle times, resulting in faster production and higher throughput.

- Enhanced Precision & Accuracy: Our CNC mill turn machines are engineered to deliver exceptional precision and accuracy. With rigid construction, high-quality components, and advanced control systems, these machines offer tight tolerances, superior surface finishes, and consistent part quality, ensuring your products meet the strictest industry standards.

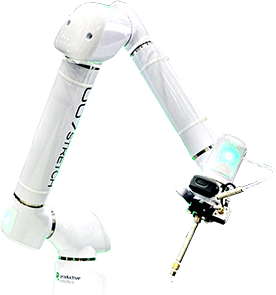

- Seamless Integration & Automation: Our mill turn machines are designed for seamless integration with automation systems, allowing for unmanned or lights-out operations. By automating your production processes, you can significantly increase productivity, reduce labor costs, and achieve round-the-clock production.

- Time & Cost Savings: By combining multiple operations into a single machine, our CNC mill turn machines help you save valuable time and reduce production costs. You can minimize setup times, eliminate workpiece transfers between machines, and optimize tool utilization, resulting in improved efficiency and profitability.

Partner with Absolute Machine Tools

When you choose Absolute Machine Tools as your CNC mill turn machine provider, you gain access to exceptional expertise, reliable support, and industry-leading solutions. Here’s why you should partner with us:

- Extensive Industry Experience: With years of experience serving various industries, we understand your unique manufacturing challenges. Our team of experts will work closely with you to understand your requirements and provide customized solutions tailored to your specific needs.

- Cutting-Edge Technology: We stay at the forefront of technological advancements in CNC machining. Our mill turn machines incorporate the latest innovations, ensuring you have access to state-of-the-art technology that enhances your manufacturing capabilities and drives your success.

- Comprehensive Support: We don’t just deliver machines; we provide comprehensive support throughout your entire journey. From installation and training to ongoing maintenance and technical assistance, our dedicated team is committed to ensuring your success and maximizing the performance of your mill turn machines.

- Uncompromising Quality: At Absolute Machine Tools, quality is our top priority. We partner with renowned manufacturers known for their precision and reliability. Our mill turn machines undergo rigorous testing to meet the highest standards, ensuring exceptional performance and durability.

Unlock the Power of CNC Mill Turn Machines

Experience the transformative power of CNC mill turn machines from Absolute Machine Tools. Our advanced technology, unmatched expertise, and unwavering commitment to your success make us the ideal partner for your manufacturing needs. Contact us today to learn more about our CNC mill turn machines and how they can revolutionize your production processes. Together, let’s take your manufacturing to new heights of efficiency and excellence.

Frequently Asked Questions About Mill/Turn Machines

Why use a CNC turning and milling machine?

A CNC turning and milling machine is a computer-controlled machine that can be used to create precision parts. The machine is operated by a trained operator who feeds it a program that tells it how to shape the piece of material. The CNC turning and milling machine can create highly accurate and repeatable results, making it an invaluable tool for manufacturers. In addition, the machine can be used to create parts with complex geometry that would be difficult or impossible to create with traditional machining methods. As a result, the turning and milling machine has become an essential tool for many manufacturers.

A CNC turning milling machine can offer many benefits over a traditional machine. For one, it can be programmed to perform a variety of tasks, meaning that it can be used for a wide range of projects. Additionally, CNC machines are highly accurate, meaning that they can produce consistent results. Finally, CNC machines are relatively fast, meaning that they can increase productivity in a workshop setting. Consequently, a CNC turn center or CNC mill center can be an essential piece of equipment for any business that relies on precision manufacturing.

A CNC milling and turning machine can be a great asset to any business that relies on machining for their production process. There are many benefits, including the fact that they are very precise, repeatable, and fast.

In addition, these machines can be programmed to produce very intricate results that would be difficult or impossible to achieve with traditional machining methods. As a result, businesses that invest in CNC technology can reap significant rewards in terms of increased productivity and improved product quality.

What are the basics of CNC milling and turning?

CNC milling and turning are two of the most common CNC machining processes. CNC milling involves using a rotating cutting tool to remove material from a workpiece. CNC turning, on the other hand, uses a non-rotating cutting tool to shape a workpiece. Both milling and turning can be performed on a variety of materials, including metals, plastics, and composites. In general, CNC milling is better suited for creating flat surfaces, while CNC turning is better suited for creating cylindrical shapes. However, both processes can be used to create a wide variety of shapes and geometry.

How does a CNC turning milling machine work?

CNC turning and milling machines are computer-controlled tools that are used to create precise, intricate parts for a variety of industries. The machines work by using a rotating cutting tool to remove material from a workpiece. The turning process is used to create cylindrical parts, while the milling process is used to create flat or irregularly shaped surfaces. Both processes can be performed on a variety of materials, including metals, plastics, and composites.

A turning and milling machine combines the functions of a lathe and a mill. These machines are typically used to produce small, intricate parts such as those used in the electronics or medical industries.

To create a part, the turning and milling machine first starts with a block of material known as a workpiece. The machine then uses a variety of tools to remove material from the workpiece, shaping it into the desired shape. The turning process involves rotating the workpiece while cutting tools are used to remove material. The milling process, on the other hand, involves moving the workpiece past a rotating cutting tool. Both processes can be performed simultaneously on a turning and milling machine, allowing for greater efficiency and accuracy.

They are capable of producing extremely precise parts, making them an essential tool in many manufacturing industries. In addition to being more precise than manual turning and milling methods, CNC machines can also produce parts faster and with less waste. As a result, CNC turning and milling machines have become an essential part of manufacturing operations around the world.

What industries use a CNC machine for milling and turning?

CNC turning and milling machines are used in a variety of industries to create precision components. Automotive, aerospace, and medical manufacturers use CNC machines to create engine parts, drive shafts, and surgical instruments.

For example, aerospace companies use CNC machines to create parts for airplanes and satellites. Automotive companies use CNC machines to create parts for cars and trucks. Medical companies use CNC machines to create implants and prosthetics. In the electronics industry, CNC machines are used to produce circuit boards and other components.

Even the food and beverage industry relies on CNC technology to create packaging and cans. As you can see, CNC turning and milling machines are an essential part of many different industries. Without them, many products would simply not be possible.