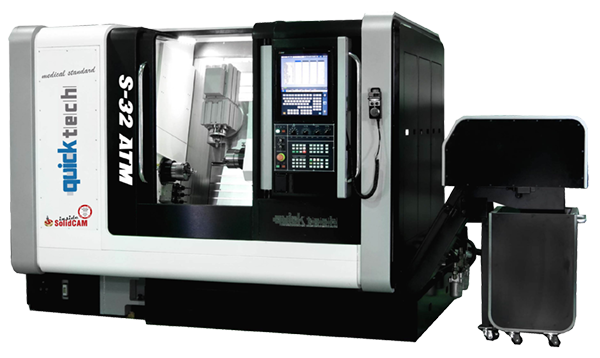

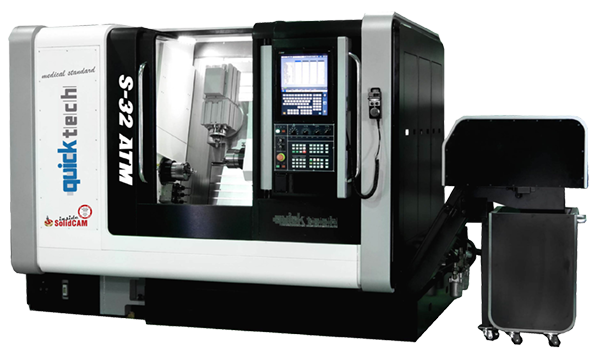

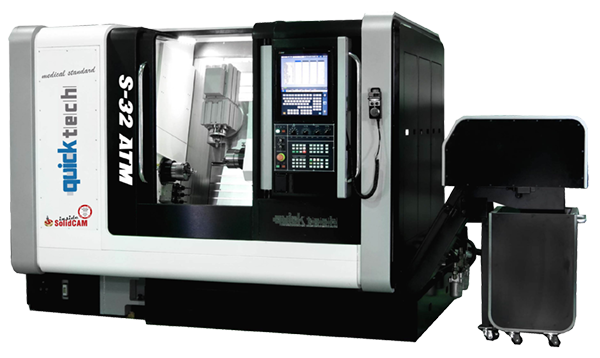

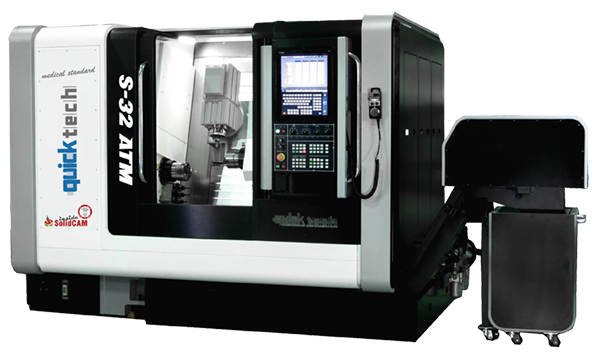

QuickTECH S-32 & S-42 ATM Compact 9-Axis Twin Spindle Mill/Turn Centers with B-Axis & ATC

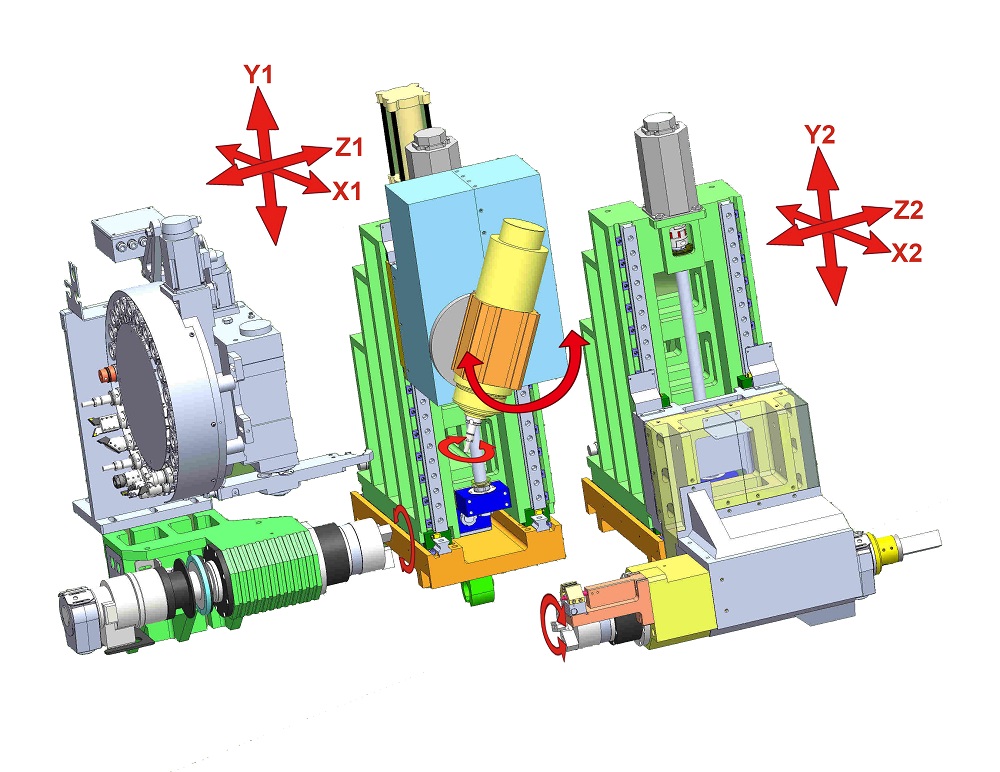

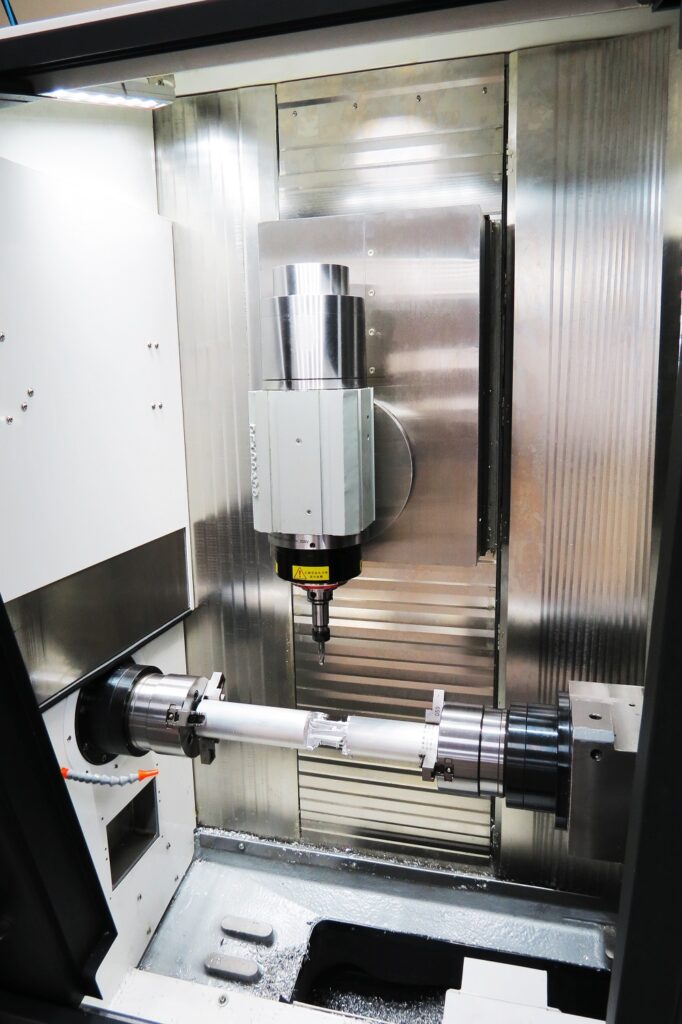

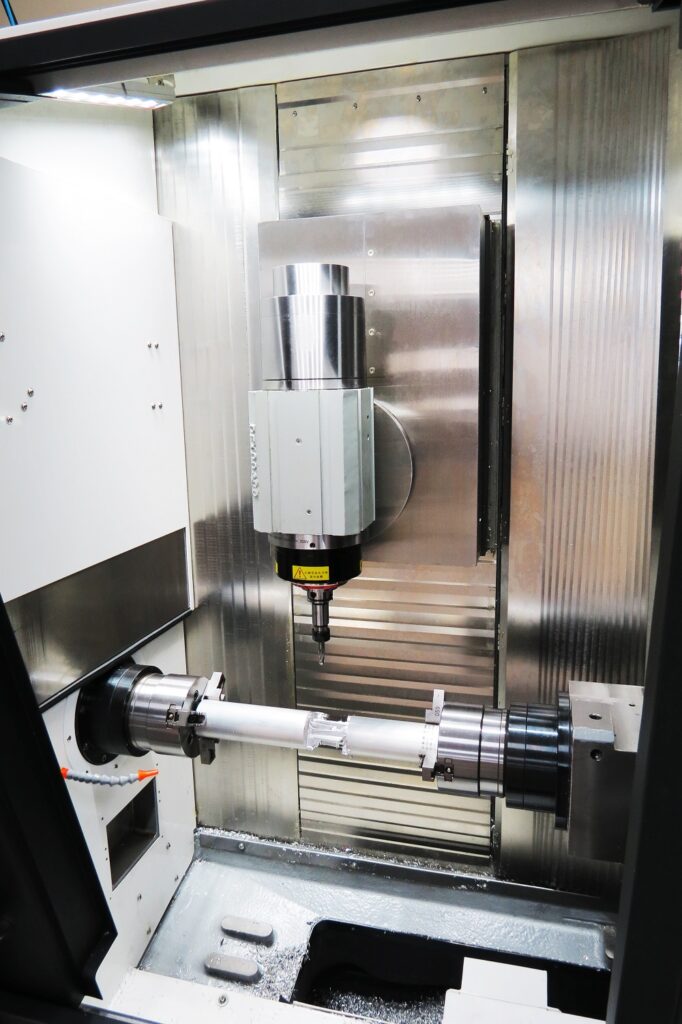

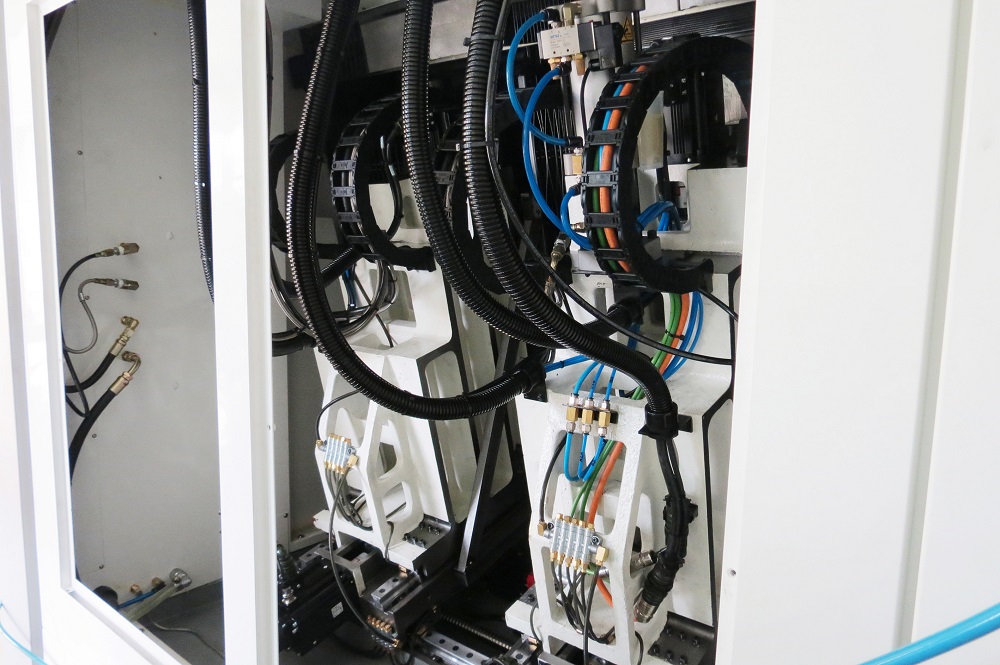

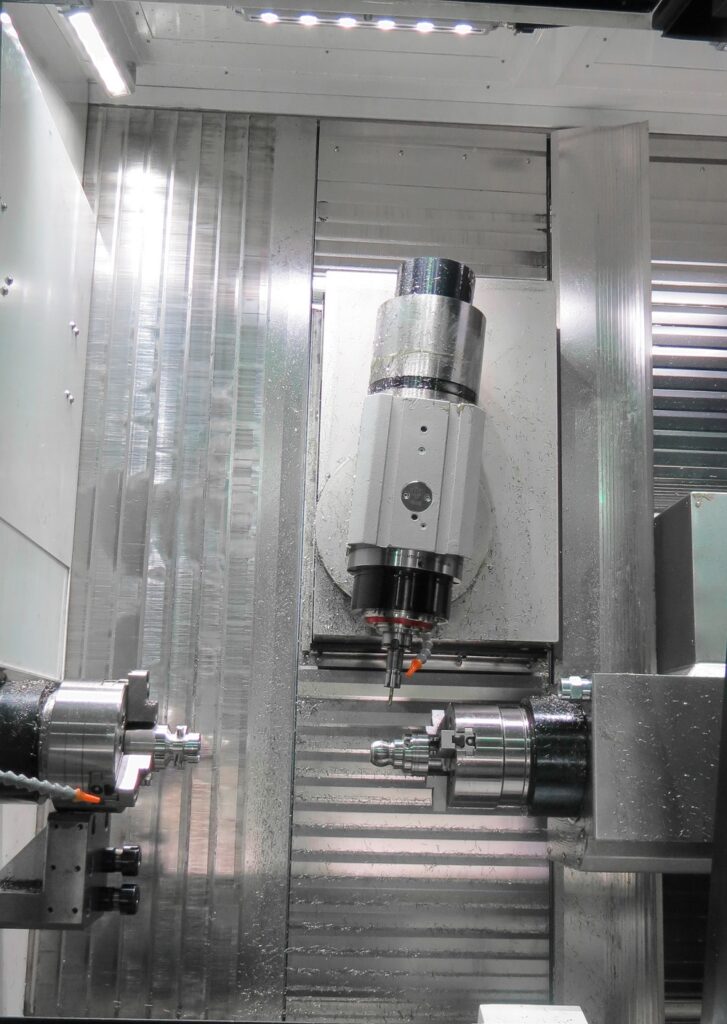

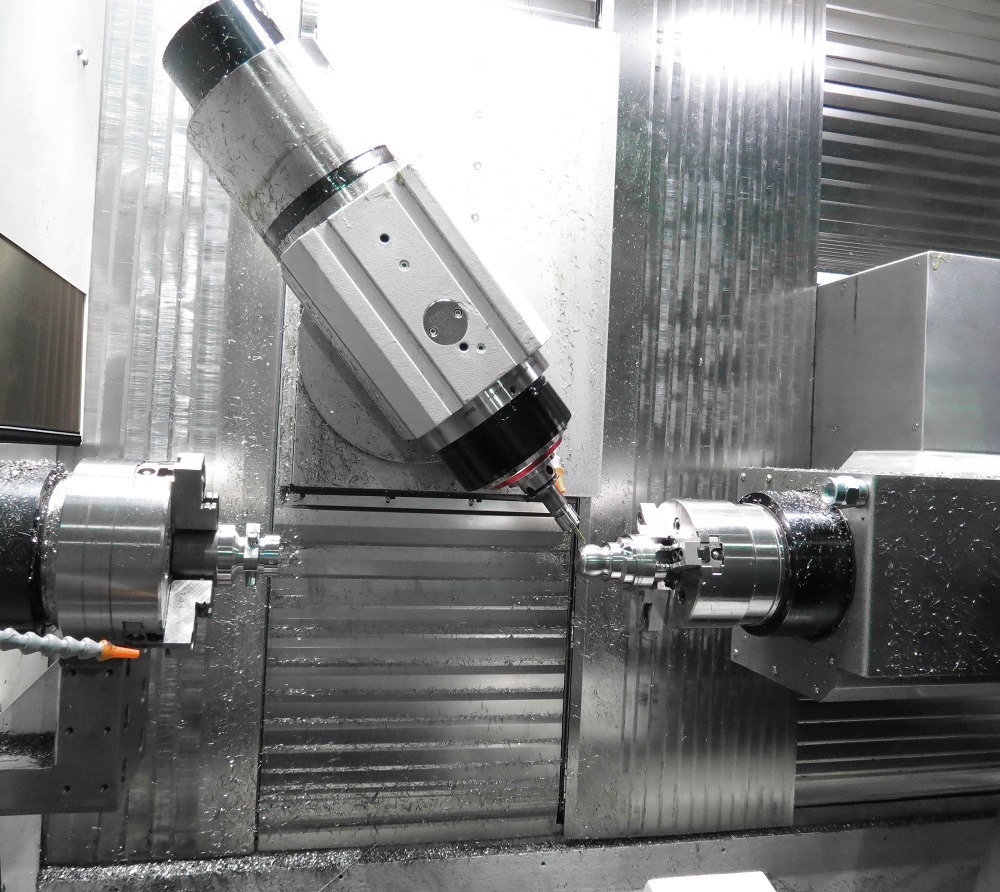

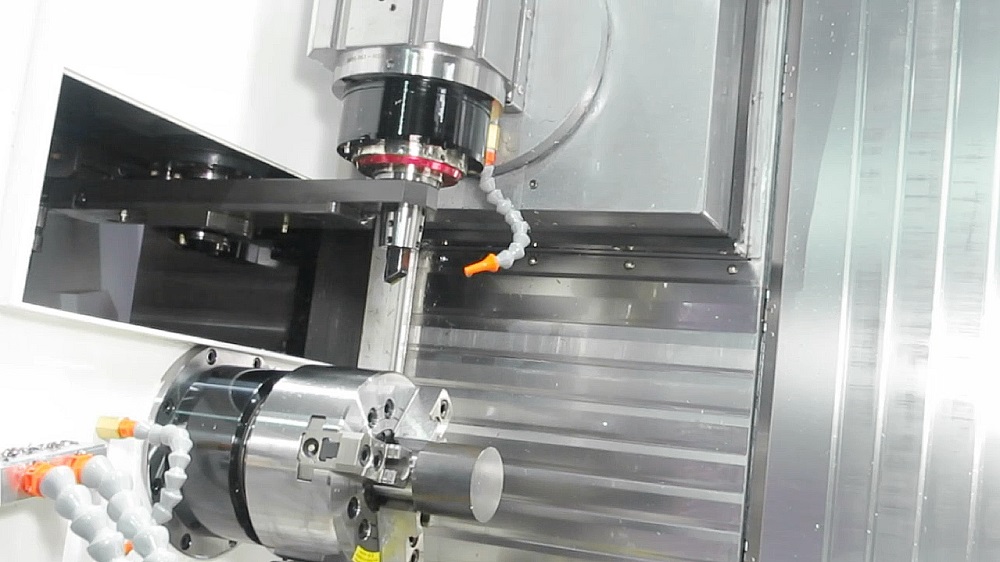

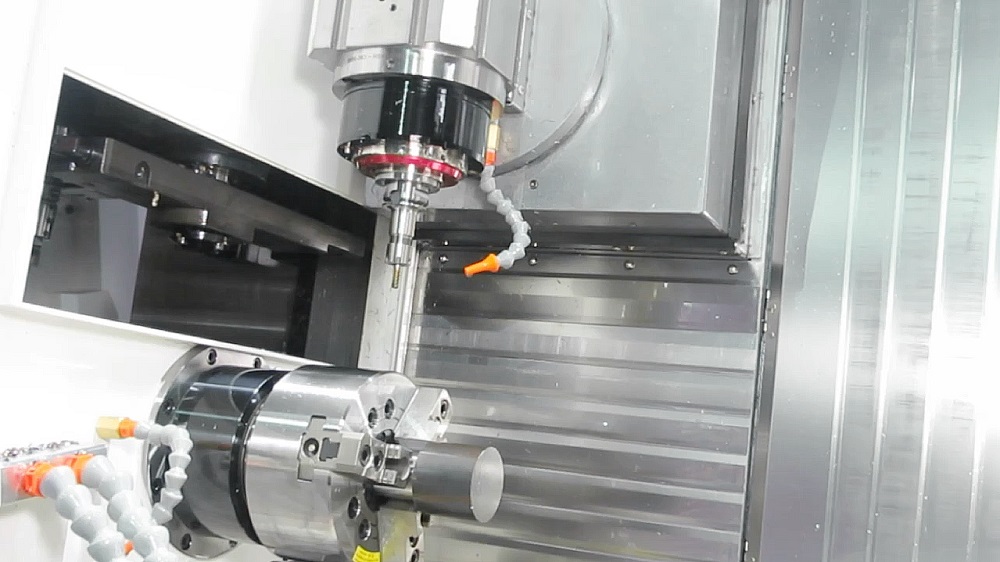

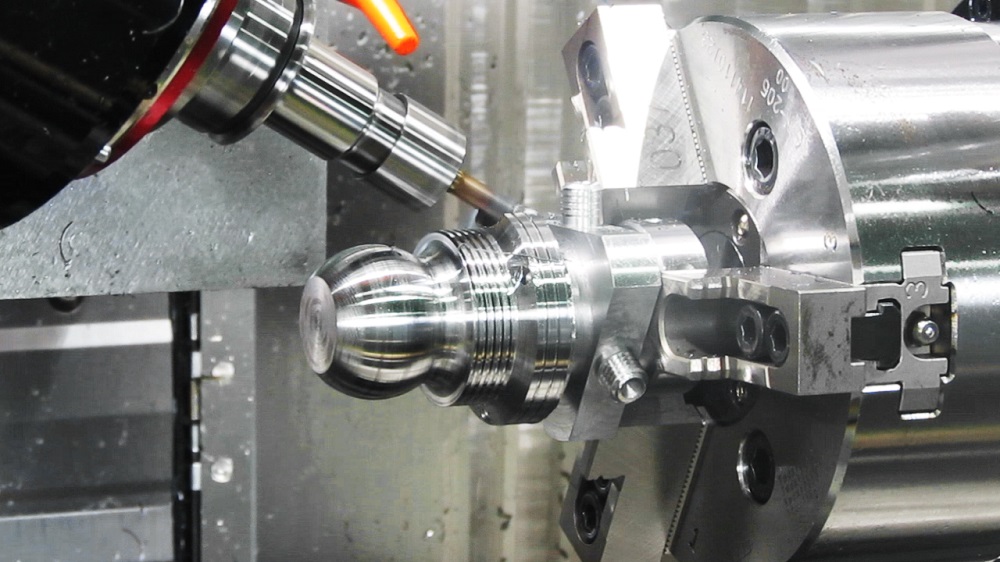

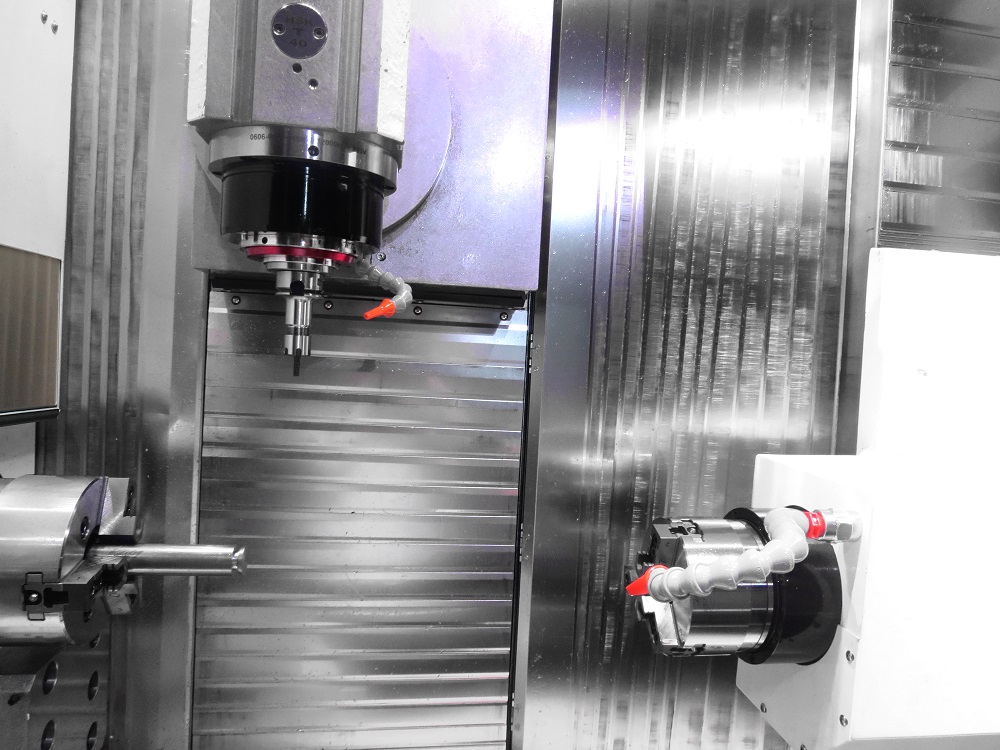

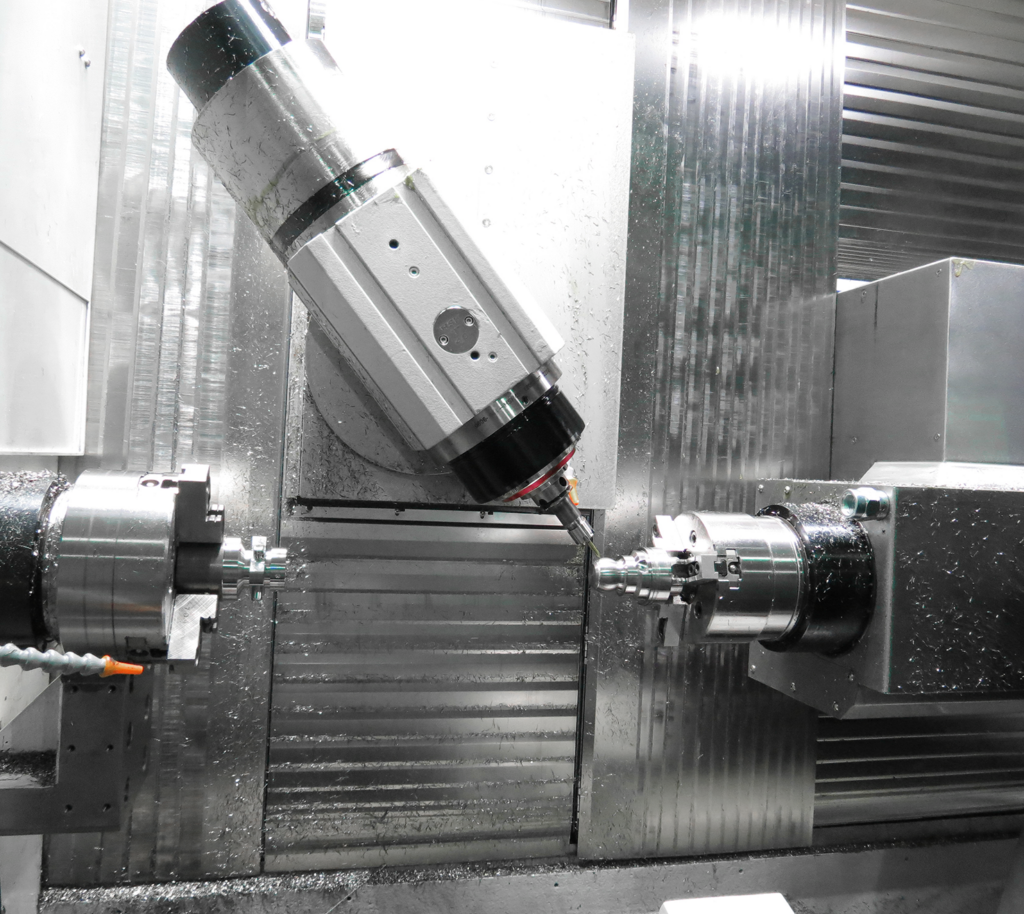

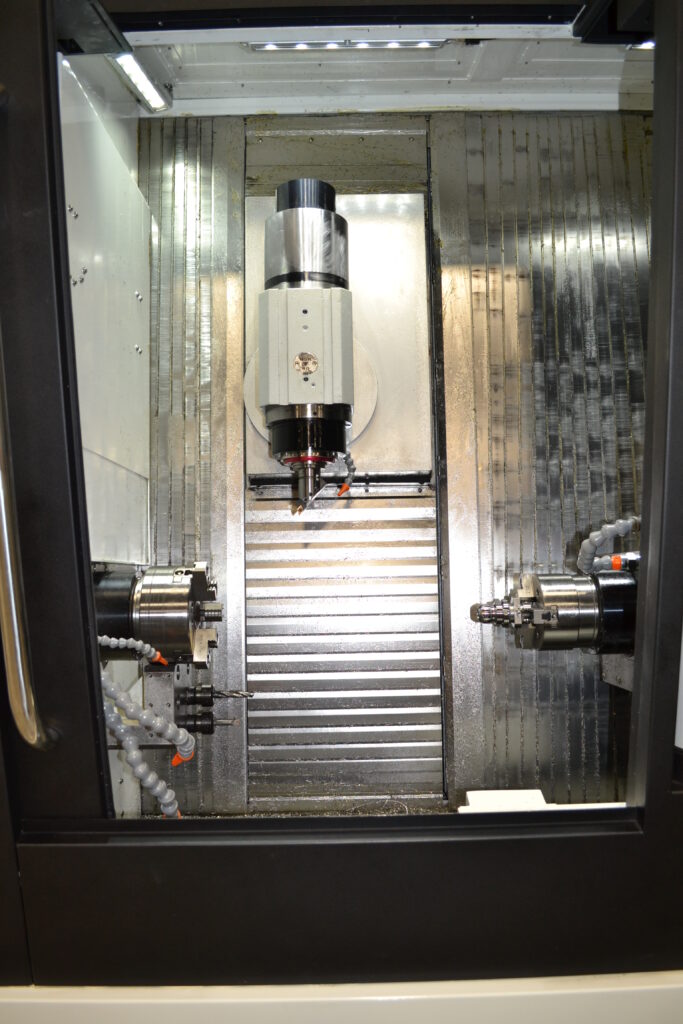

The QuickTECH S-32 ATM is compact mill/turn center for small, complex parts. It combines precision integral motor main and sub spindles for turning with B-axis milling head and ATC to produce complex parts. Utilizing a unique 3-axis movement of the sub-spindle, machine physical size is minimized by the sub-spindle’s ability to move in the X-axis above and below the center line out of the way of the B-axis milling spindle. This high production CNC turning center is cast from Meehanite iron. With a 30mm bar capacity, this unique bar processing center provides complete part machining including all complex milling functions. The S-32 ATM features 9 total axes, 2 turning spindles, a B-axis milling spindle with 24 tool auto tool change, and 6 fixed sub-spindle turning tools for a total capacity of 30 tools.

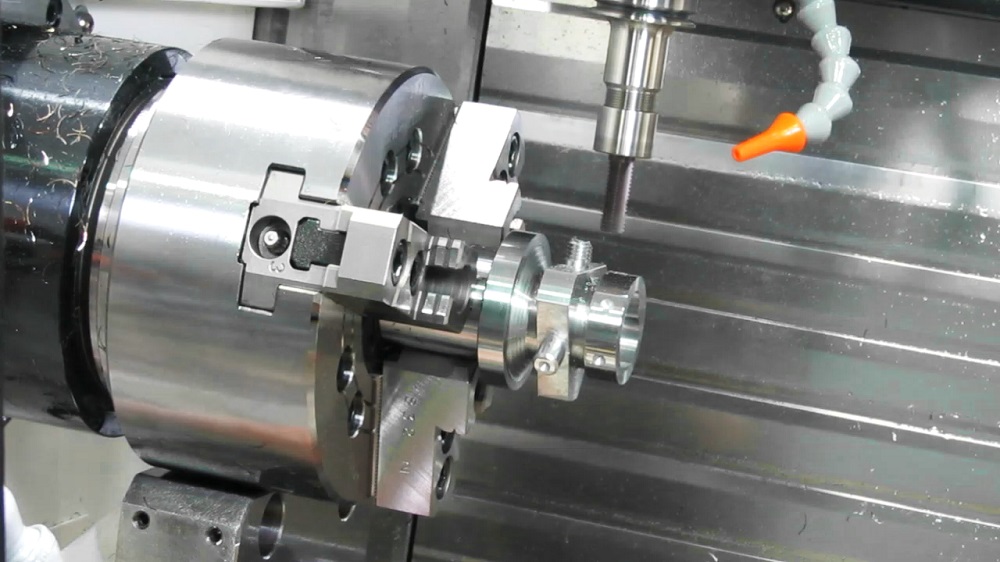

Turning Spindles

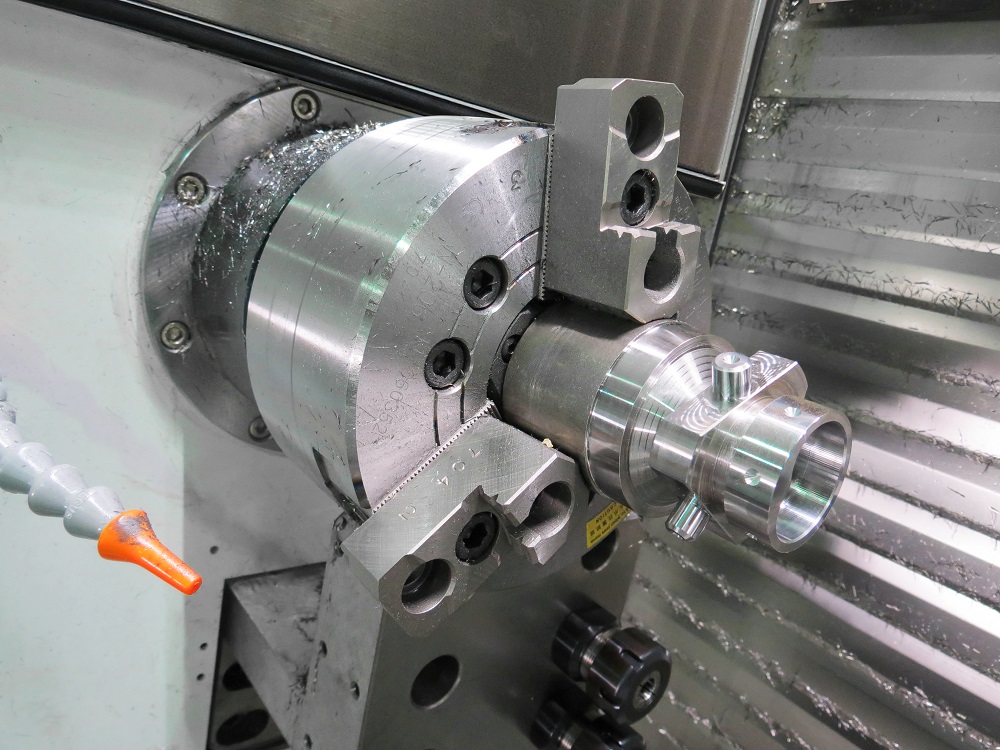

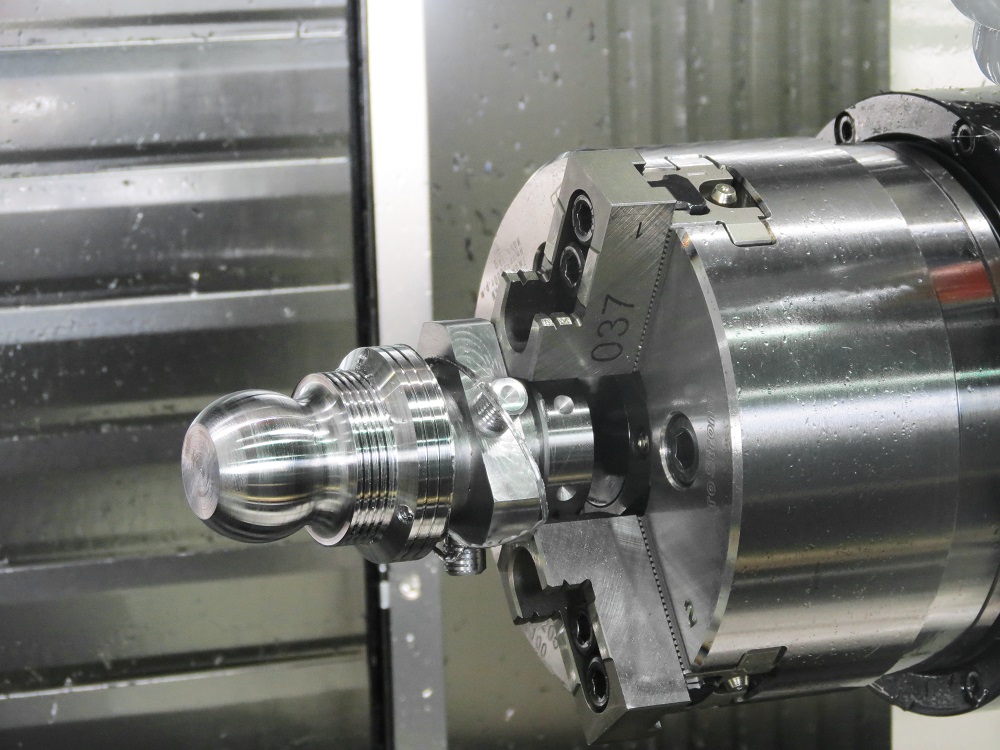

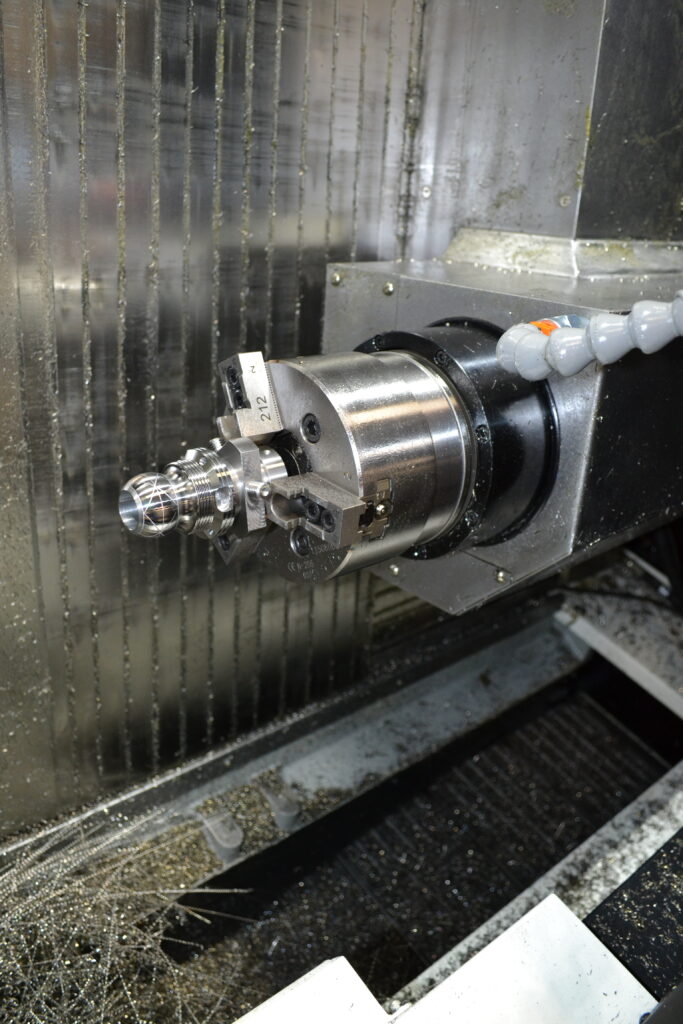

The main spindle sports a 5 HP high torque integral motor. The sub-spindle is equipped with a 5 HP high torque integral spindle motor for backworking. The main and sub spindles have 42mm collet chucks (or 5” 3 jaw hydraulic chucks) with 30mm bar capacities. Both 6000 RPM spindles feature a full continuous C-axis with braking system. The main and sub-spindle are synchronized for fast and accurate part transfer. Both spindles employ P4 high precision bearings for stability and heavy cutting ability.

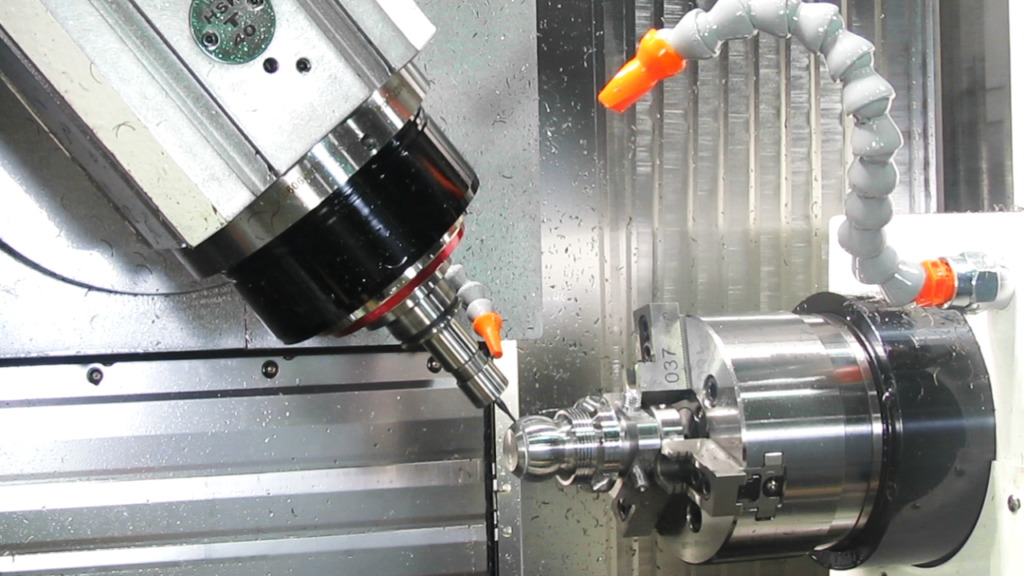

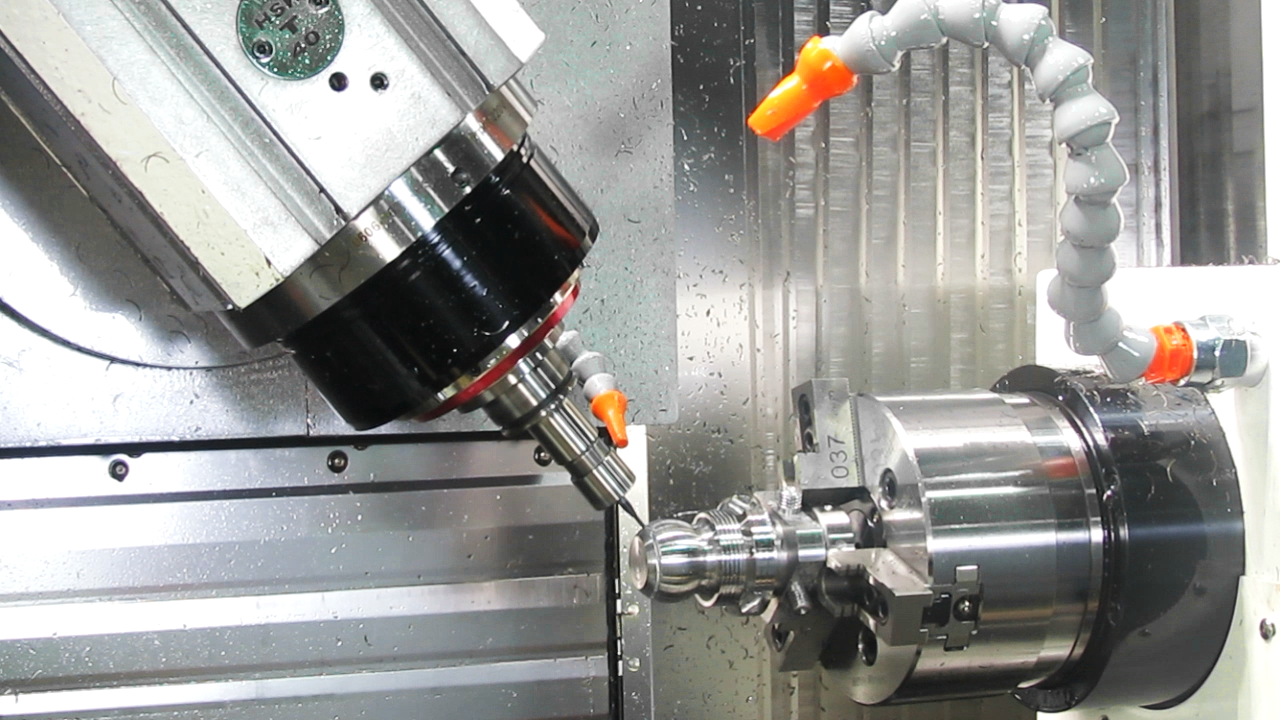

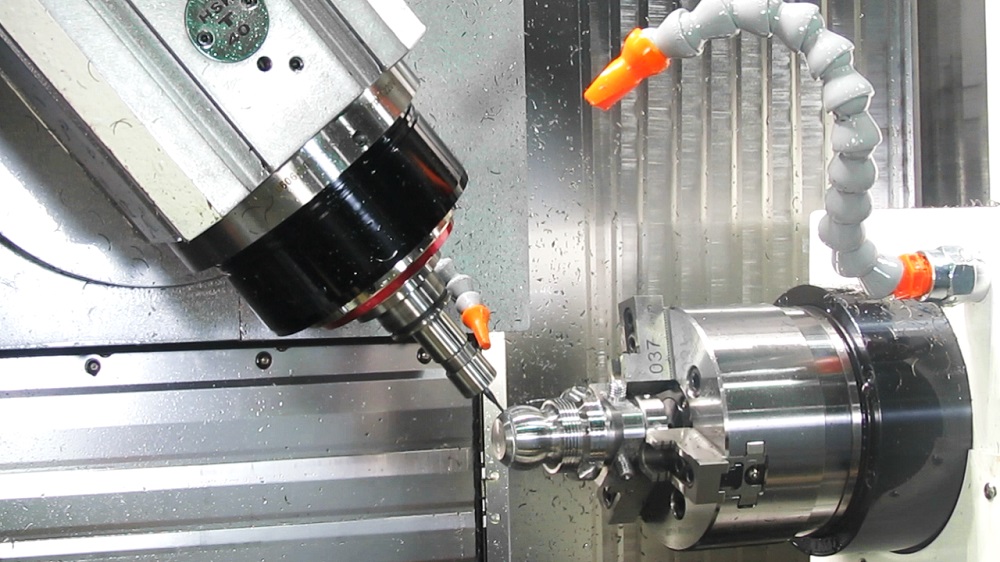

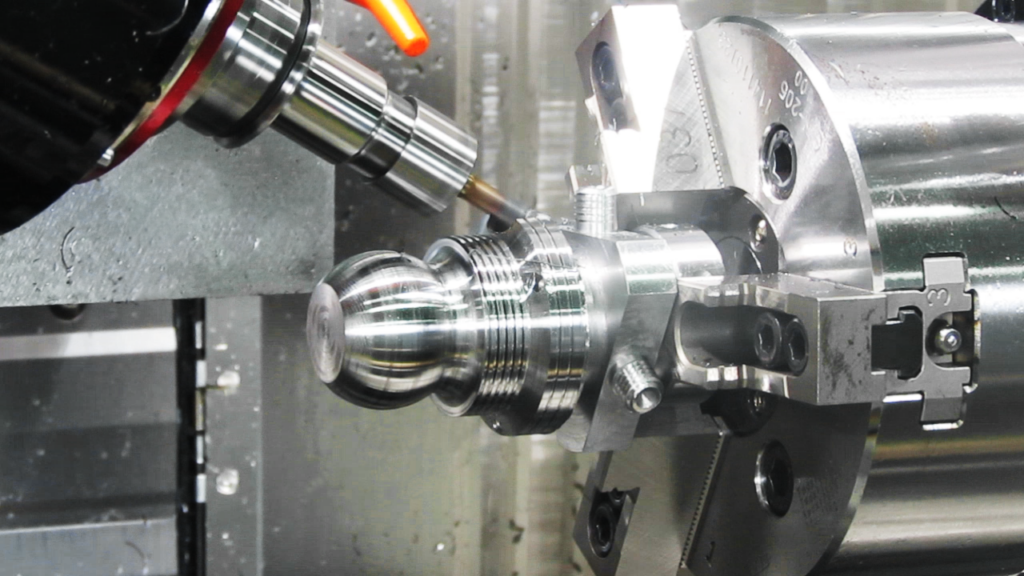

Tooling System

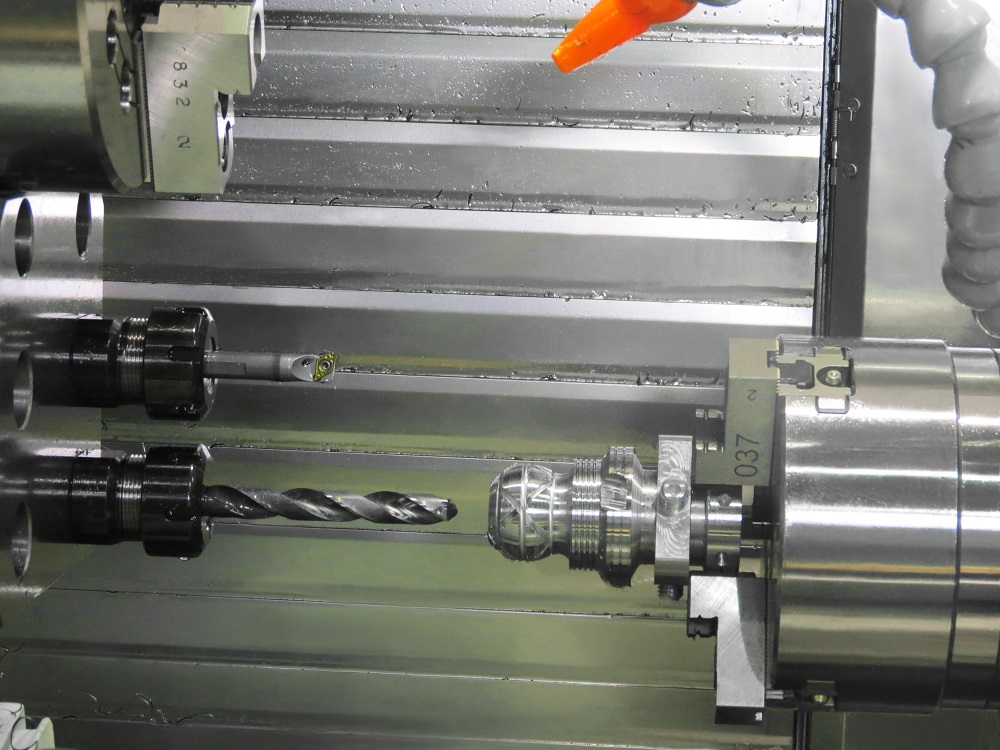

A B-axis milling spindles serves both spindles. The B-axis integral spindle motor delivers 3 HP and 10,000 RPM. Utilizing a 24 tool arm type tool changer and HSK-40T tooling system, the spindle is locked in position by coupling for rigid turning operations. Tool change time tool-to-tool is only 1.3 seconds. The B-axis has a working range of 190° (+/- 95° from vertical). Six gang-type fixed turning tools are standard for the sub-spindle, allowing simultaneous machining operations. Rigid tapping is standard.

Specifications

| Item / Model |

S-32 ATM

Request a Quote |

S-42 ATM

Request a Quote |

|---|---|---|

|

Main Spindle Capacity | ||

|

Max Bar Working Capacity |

1.18 (30mm) |

1.65″ (41mm) |

|

Max Turning Length |

15.7″ O.D. / 6.3″ I.D. |

9.8″ |

|

Collet Chuck Size |

5″ 3-Jaw Hydraulic |

6″ 3-Jaw Hydraulic |

|

Spindle Speed Range (std.) |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

5 HP Integral Motor |

15 HP Belt Drive |

|

C-Axis Increment |

.001° |

.001° |

|

Sub-Spindle Capacity | ||

|

Max Bar Working Capacity |

1.18 (30mm) |

1.18 (30mm) |

|

Max Turning Length |

11.8″ O.D. / 2.17″ I.D. |

11.8″ O.D. / 2.17″ I.D. |

|

Collet Chuck Size |

5″ 3-Jaw Hydraulic |

6″ 3-Jaw Hydraulic |

|

Spindle Speed Range (std.) |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

5 HP |

5 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Milling Spindle and ATC | ||

|

Spindle Speed Range (std.) |

10,000 RPM |

12,000 RPM |

|

Spindle Motor |

3 HP |

13 HP |

|

B-Axis Increment |

.001° |

.001° |

|

Tool System |

HSK-40T |

HSK-40T |

|

Automatic Tool Changer |

24 Tools (36 opt.) |

24 Tools (36 opt.) |

|

Tool Change Time Tool-to-Tool |

1.3 Seconds |

1.3 Seconds |

|

Sub-Spindle Tooling System | ||

|

Tooling Type |

Gang – Fixed |

Gang – Fixed |

|

Number of Tools |

6 |

6 |

|

Tooling System |

ER-20 (ER-25) Collets |

ER-20 (ER-25) Collets |

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

General | ||

|

CNC Control |

Mitsubishi M830W |

Mitsubishi M830S |

|

Machine Dimensions with Chip Conveyor |

150″ x 87″ x 81″ |

150″ x 87″ x 81″ |

|

Machine Weight |

9,570 lbs. |

9,670 lbs. |