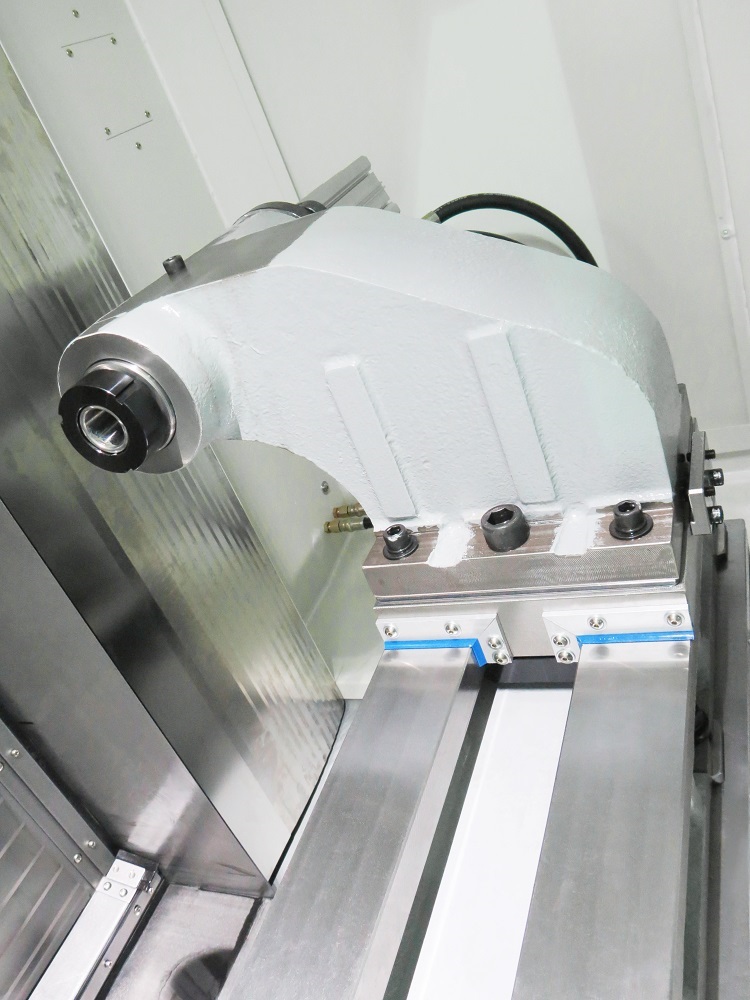

QuickTECH i-42 / i-60 Eco 4-Axis / 5-Axis Mill/Turn Centers with Tailstock

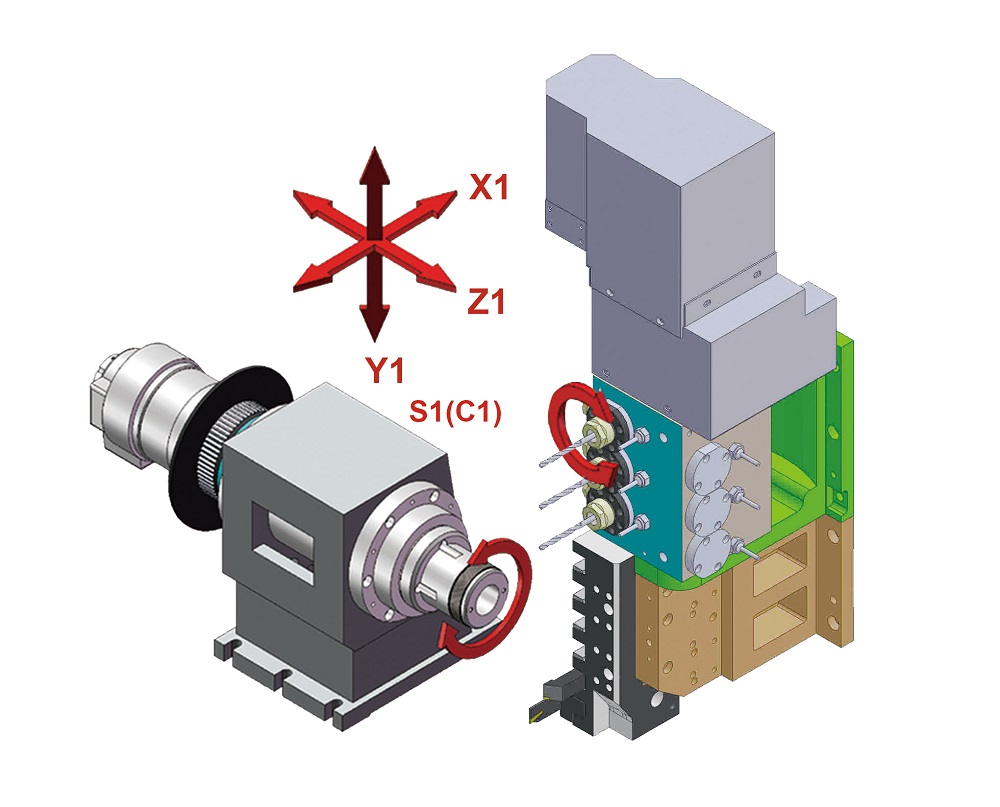

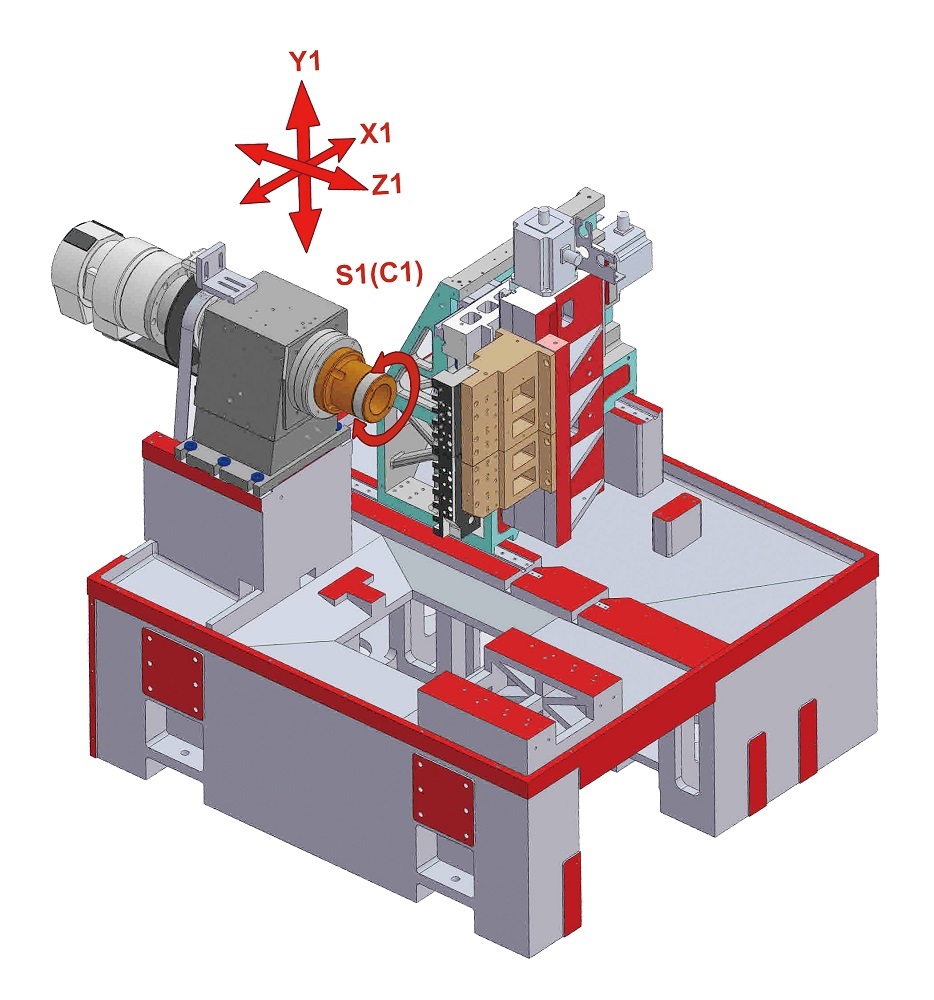

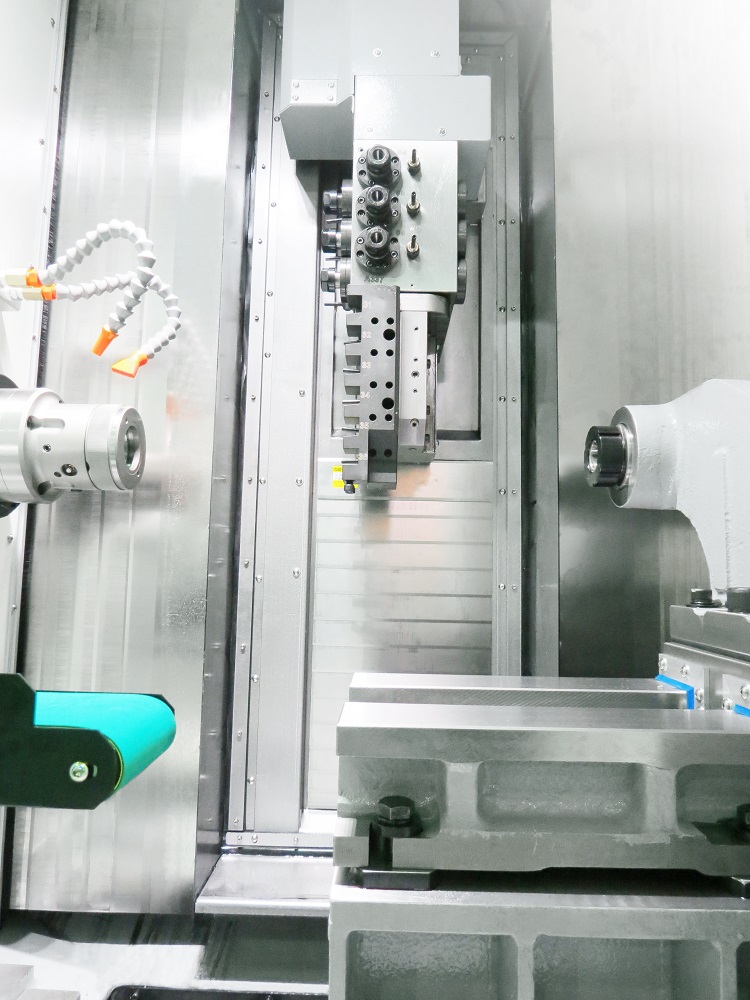

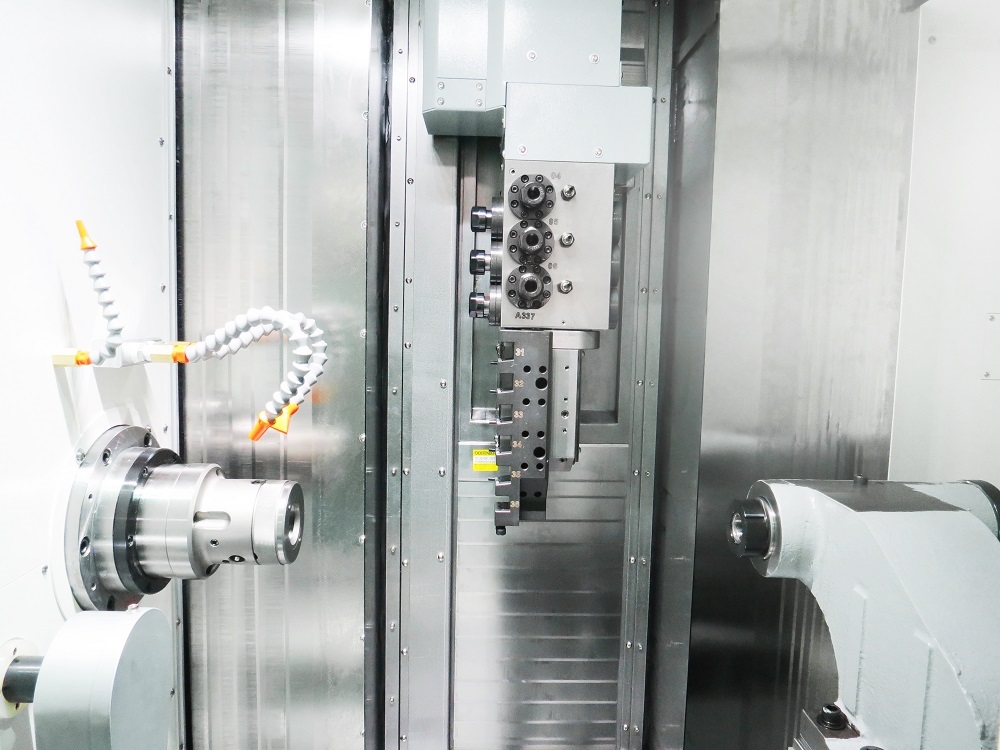

The QuickTECH i-42 / i-60 Eco is a compact, high precision, high production CNC mill/turn center cast from Meehanite iron. Available in both 42mm and 60mm bar capacities, this unique bar processing center provides complete single operation part machining including all complex milling functions. The i-42 / i-60 Eco features 4 axes (5 axes with optional B-axis), 1 turning spindle, a tailstock, and a total capacity of 17 tools (23 tools with B-axis). A 4-axis (X,Y,Z,B) gang-type vertical tool post serves the spindle.

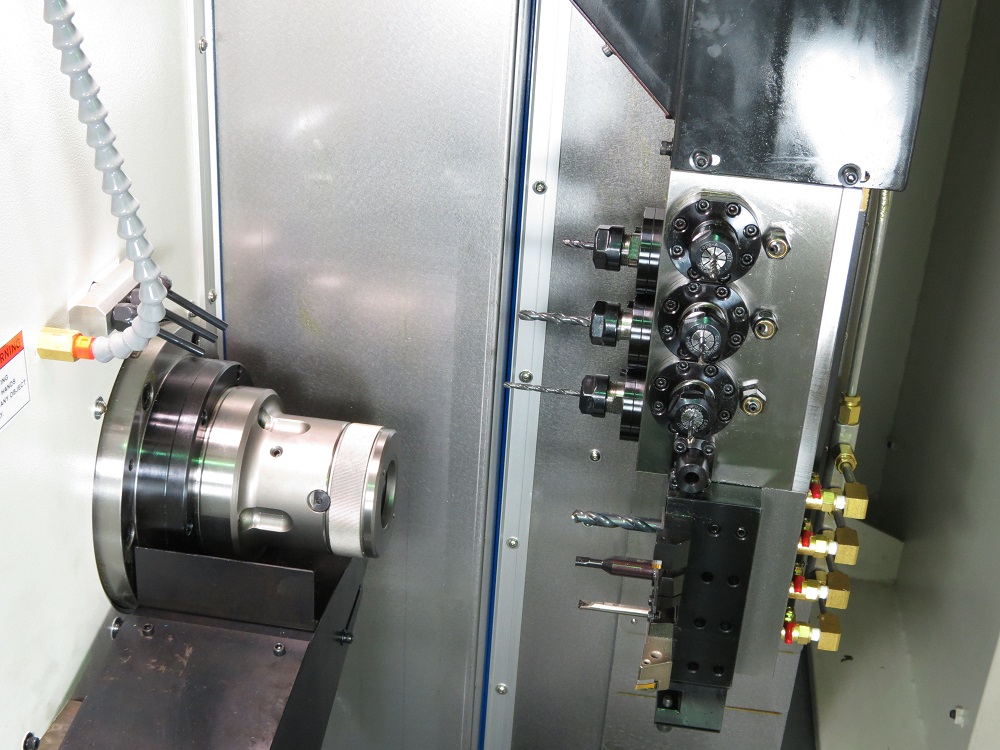

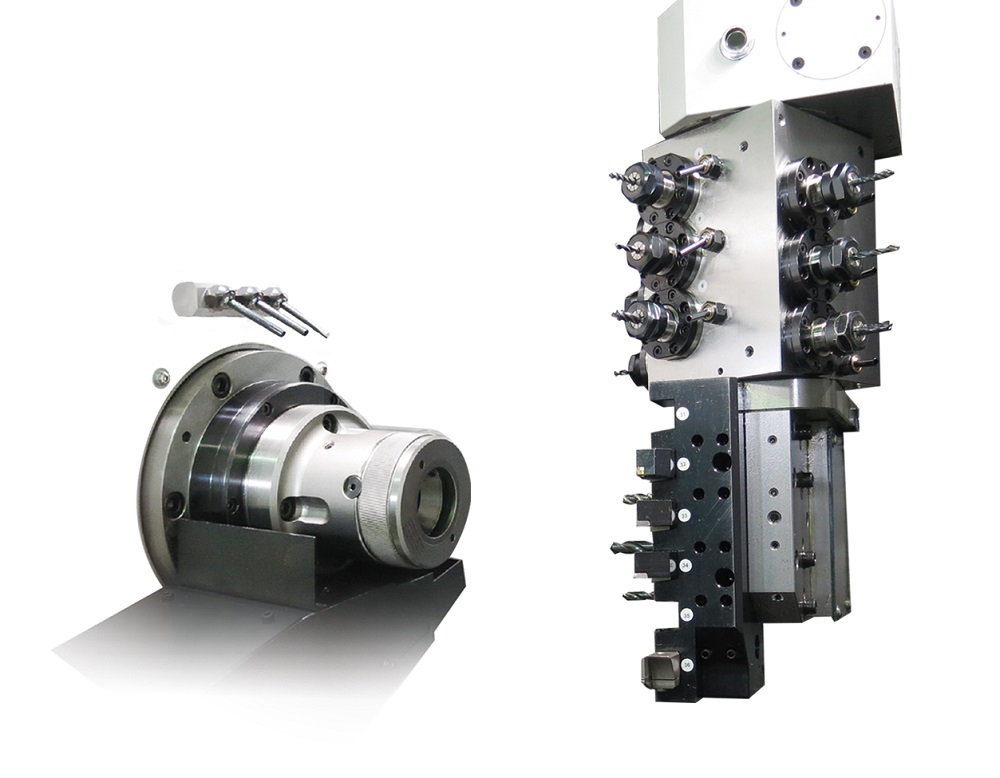

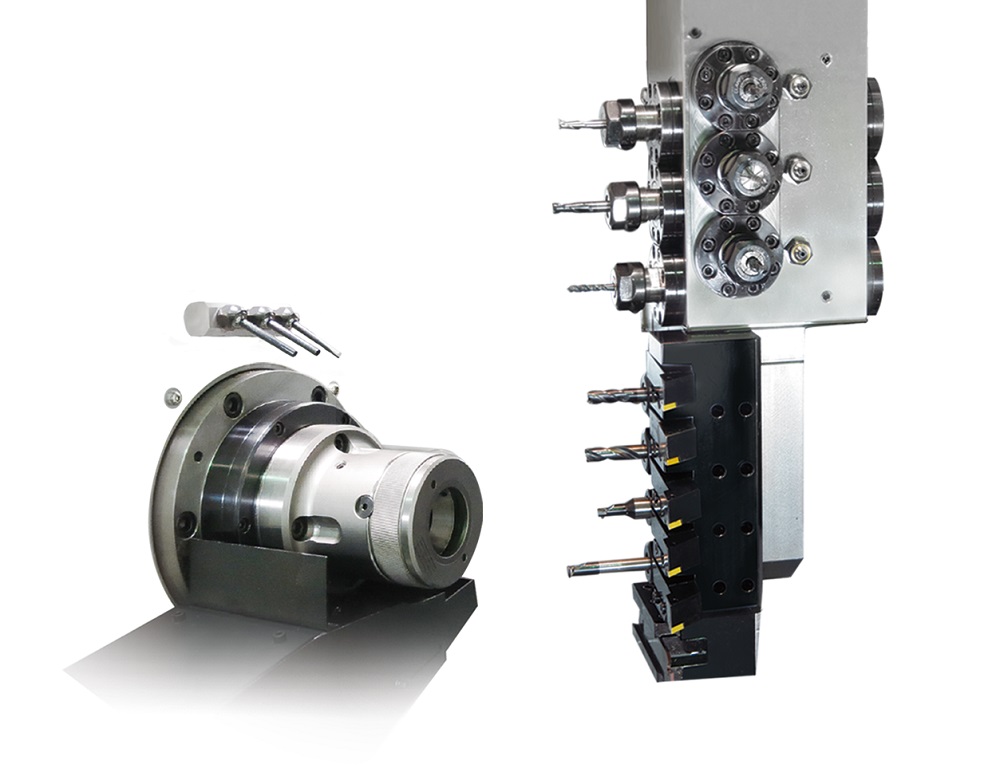

Turning Spindle

The main spindle sports a 15 HP high torque spindle motor. The main spindle has a 42mm bar capacity (60mm for i-60). The spindle features a full continuous C-axis with braking system and are both standard with 42mm DIN-173E-42B collet chucks (60mm DIN-185E-60B for i-60). The main and sub-spindle are synchronized for fast and accurate part transfer. Both spindles employ P4 high precision bearings for stability and heavy cutting ability.

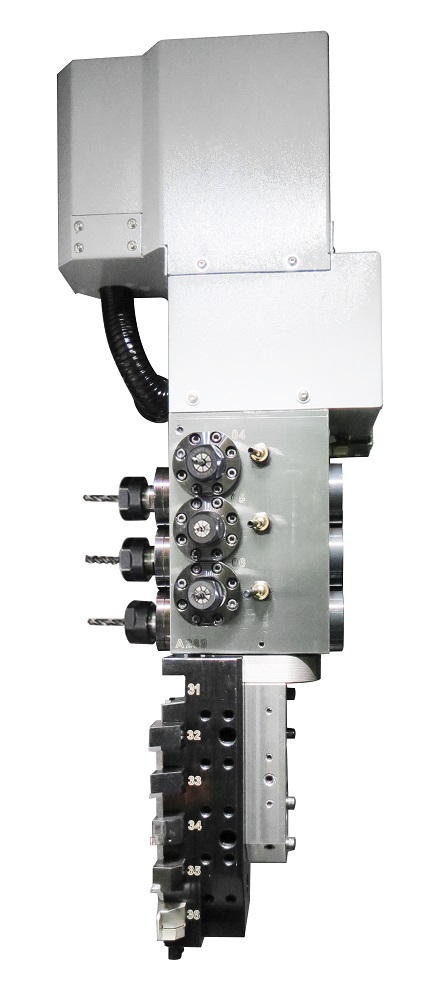

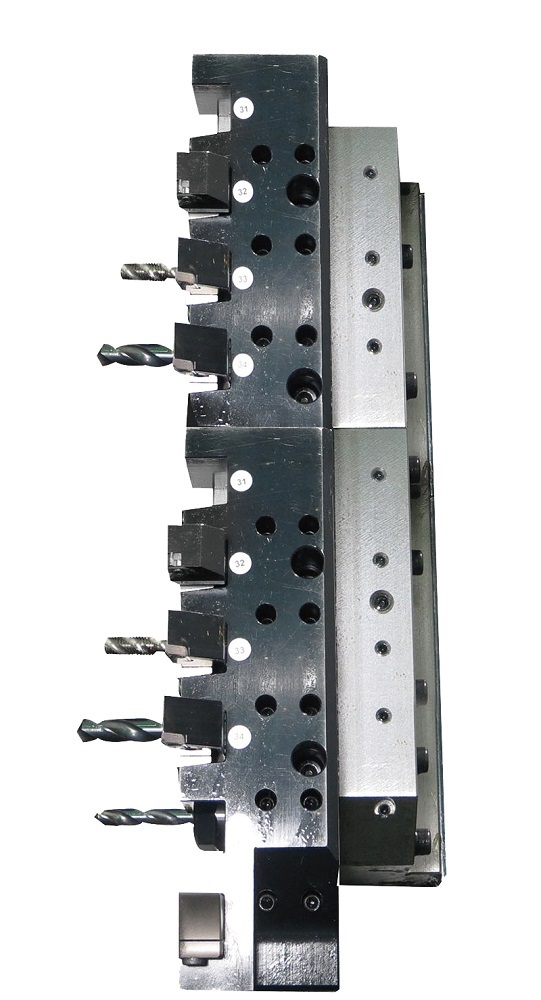

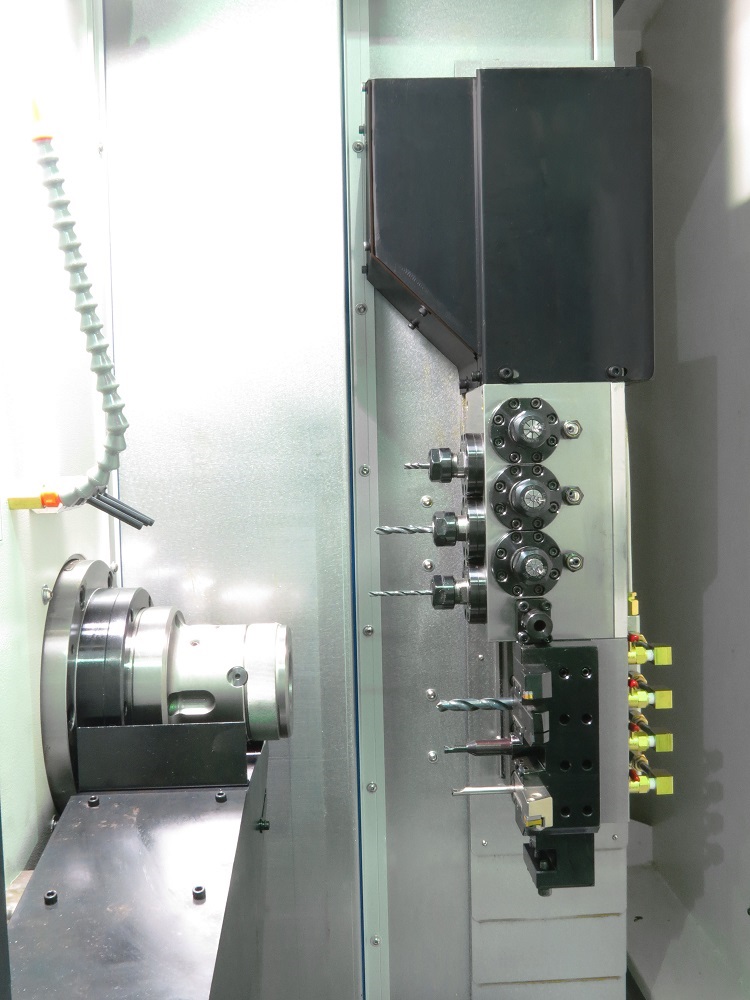

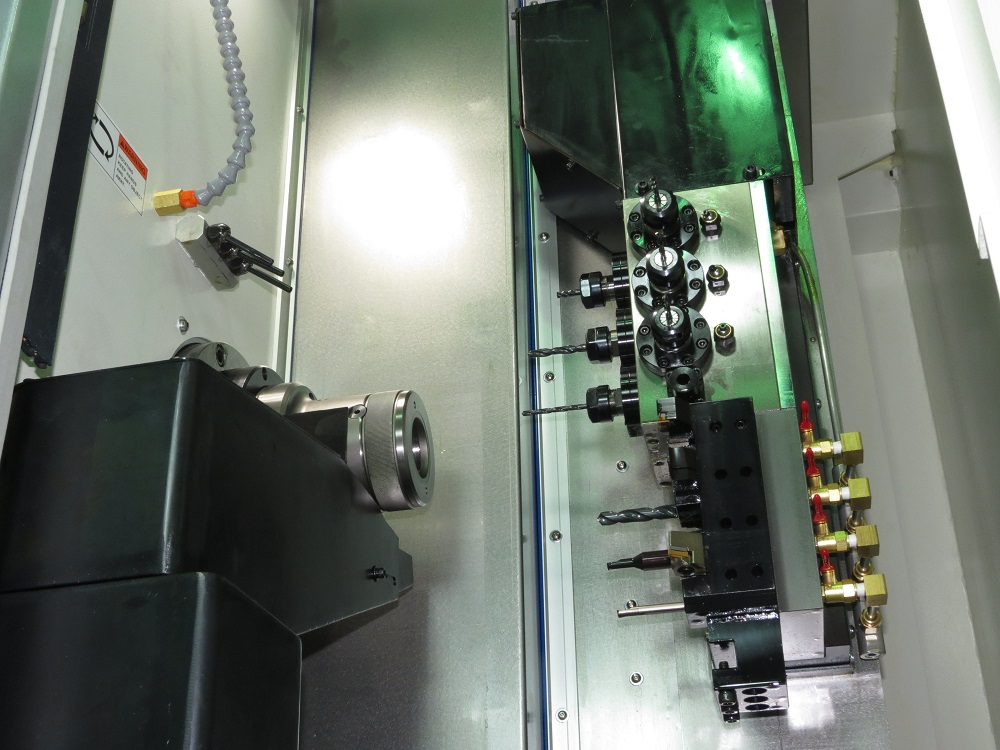

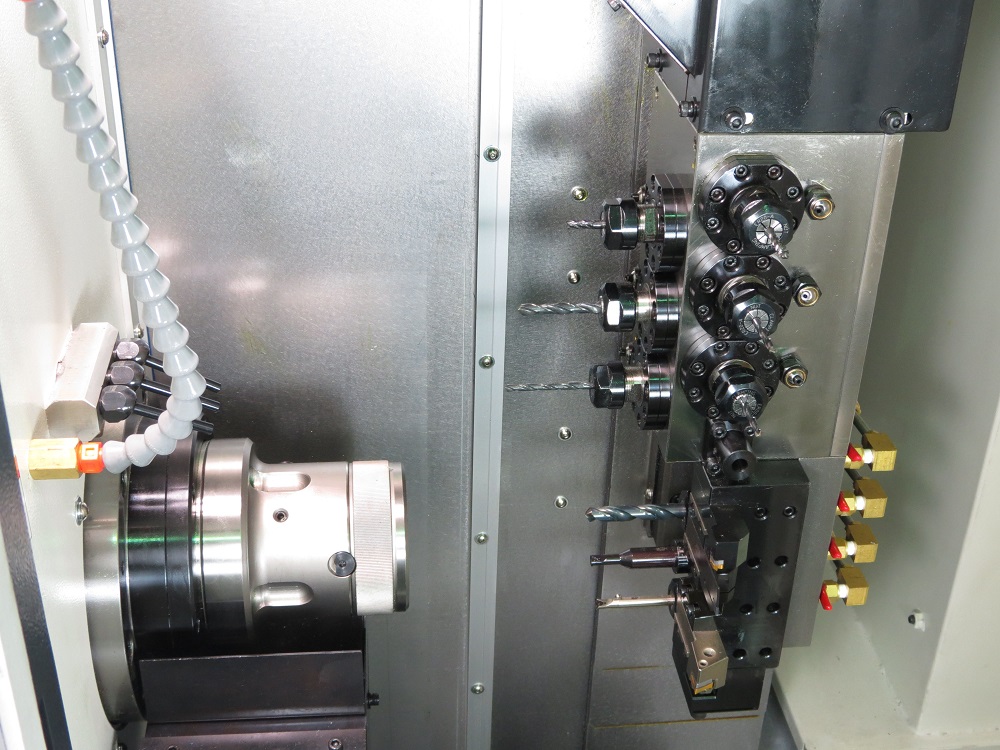

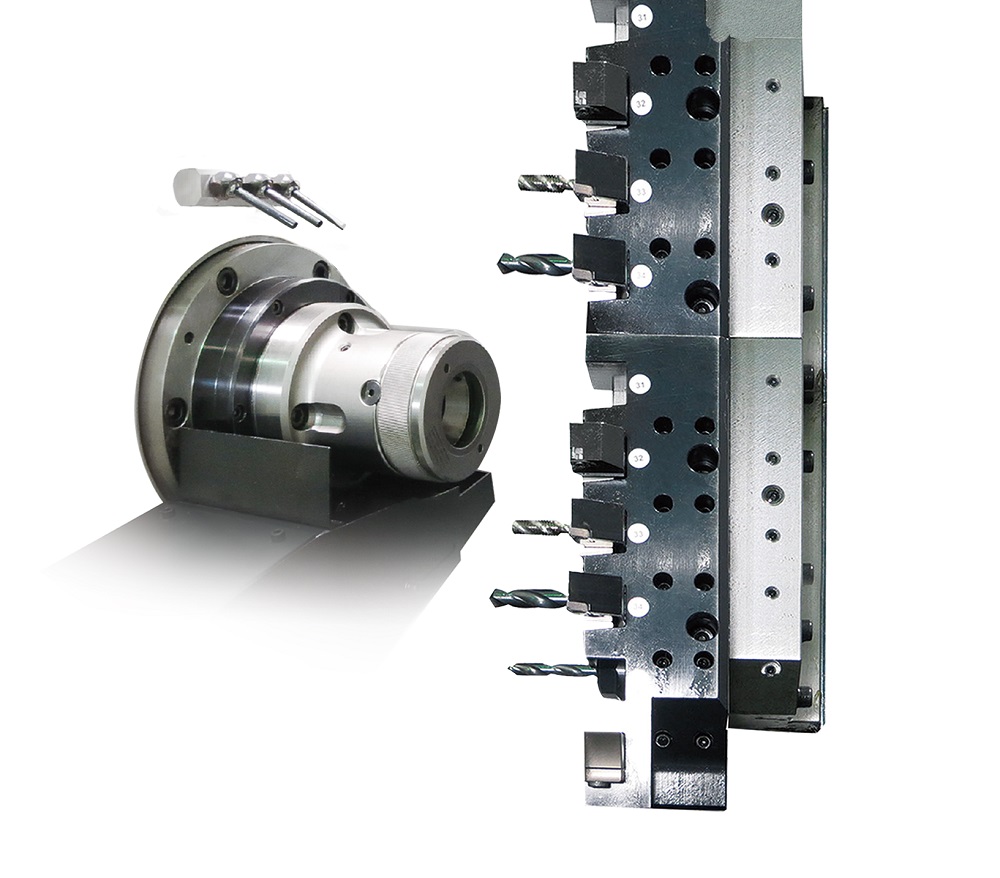

Tooling System

A unique single 4-axis gang tooling system consisting of linear X,Y, and Z axes plus an optional rotary B-axis serves the main spindle. The tool post features 6 O.D. turning tools, 5 I.D. turning tools, and 6 live tools (12 with B-axis). The fixed live tools are 3 axial and 3 radial but can also be mounted in a continuous 360° B-axis allowing 12 tools. The live tools are powered by a 2 HP spindle motor. Rigid tapping is standard. The tool post has a Y-axis for off-center milling operations. Tool change time is near ZERO. In addition our standard tooling system is Kennametal KM-25 quick change. KM-25 bases are supplied with the machine for O.D. turning tools.

CNC Controls

The machine is equipped standard with the fully featured and powerful Mitsubishi M80A control with 10.4” LCD.

Specifications

| Item / Model |

i-42 Eco

Request a Quote |

i-60 Eco

Request a Quote |

|---|---|---|

|

Main Spindle Capacity | ||

|

Max Bar working Capacity |

1.65″ |

2.36″ |

|

Max Turning Length |

9.8″ |

9.8″ |

|

Spindle Speed Range (std.) |

6,000 RPM |

4,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Tailstock | ||

|

Quill Travel |

6.3″ |

6.3″ |

|

Tailstock Body Travel |

15.35″ |

15.35″ |

|

Programmable Tailstock (opt.) |

MT #5 |

MT #5 |

|

Spindle Nose |

A2-5 |

A2-5 |

|

Hole through Draw Tube |

1.181″ |

1.181″ |

|

Spindle Speed Range |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

7.5 HP Integral Motor |

7.5 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

Tooling System | ||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

6 O.D. (5 + 1 Cut-Off) / 5 I.D. |

6 O.D. (5 + 1 Cut-Off) / 5 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ER-20) |

.75″ (ER-20) |

|

B-Axis (opt.) |

360° |

360° |

|

B-Axis Index Time (opt.) |

.3 Seconds 90° / .6 Seconds 360° |

.3 Seconds 90° / .6 Seconds 360° |

|

Number of Live Tools |

6 (12 with B-Axis) |

6 (12 with B-Axis) |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

General | ||

|

Machine Dimensions with Chip Conveyor |

132″ x 60″ x 77″ |

132″ x 60″ x 77″ |

|

Machine Weight |

6,050 lbs. |

6,050 lbs. |