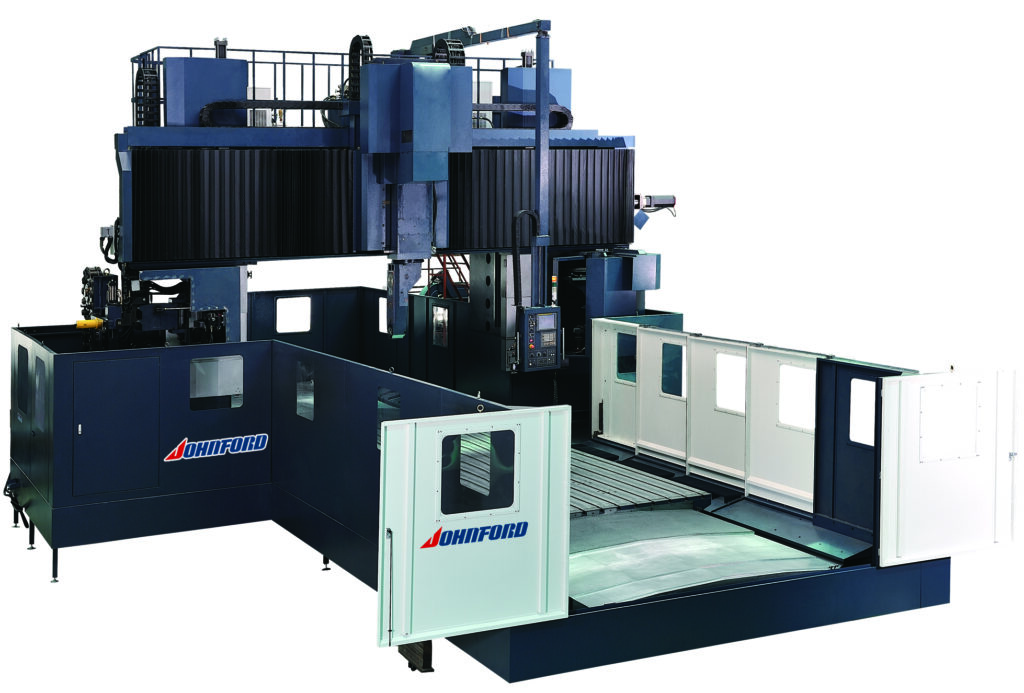

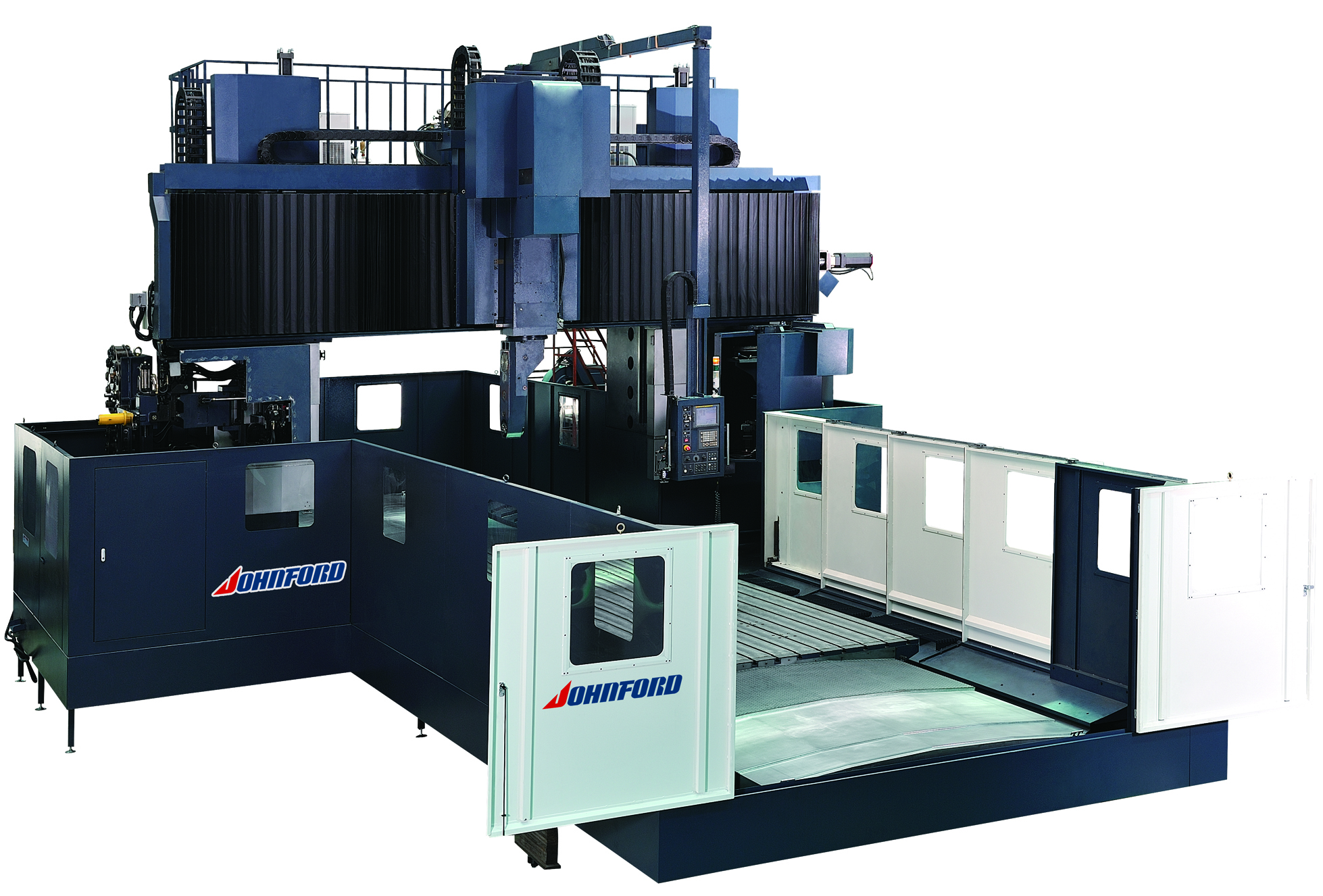

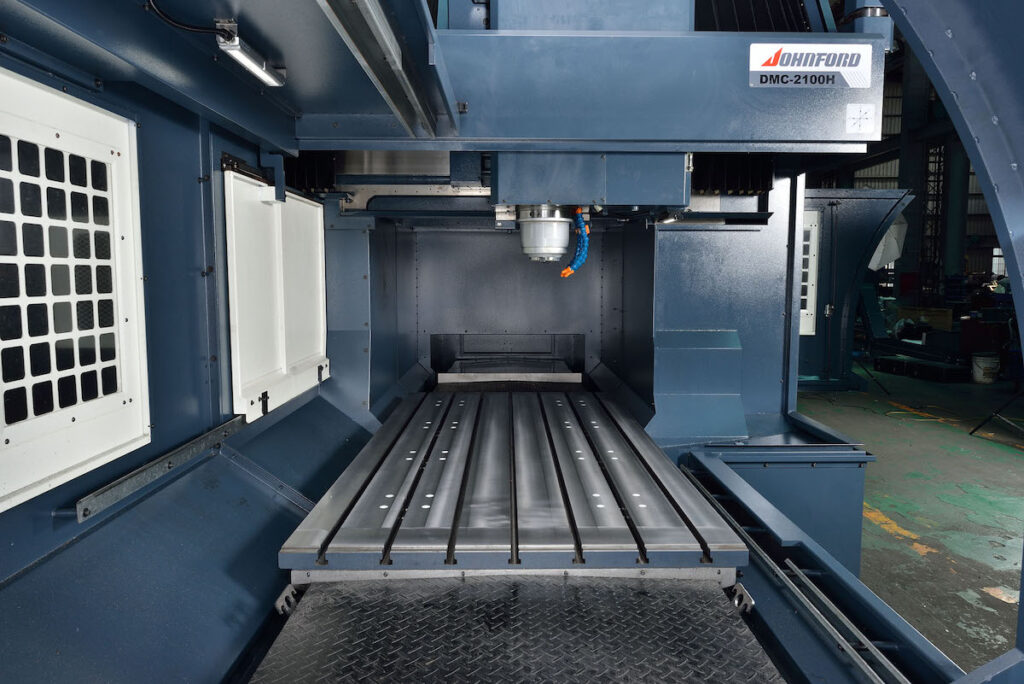

Johnford DMC Series 1600mm – 6100mm Moving Table/Fixed Column Bridge Mills

Johnford is renowned worldwide for building some of the heaviest and most rugged CNC bridge mills in the industry — a reputation earned over decades since the company’s founding in the late 1970s. The DMC-1600 to DMC-6100 series features a fixed-column, moving-table design that delivers exceptional rigidity and versatility while conserving valuable floor space. With expansive standard configurations and optional accessories, this series is designed to meet the needs of virtually every metal-cutting manufacturer.

Looking for a different size/capability? Check out other models in the DMC Series:

Built for Exceptional Rigidity and Performance

Johnford’s philosophy for high-end double-column machining centers starts with heavy Meehanite castings produced in its own foundry, ensuring the highest quality from the ground up. Dense, fine-grain cast iron provides outstanding vibration damping for superior surface finishes and long tool life. The unique one-piece bridge and columns casting, combined with a full-length Meehanite base, delivers 100% table support over the entire travel range, while hardened and ground box ways in both Y and Z axes absorb heavy cutting forces with ease.

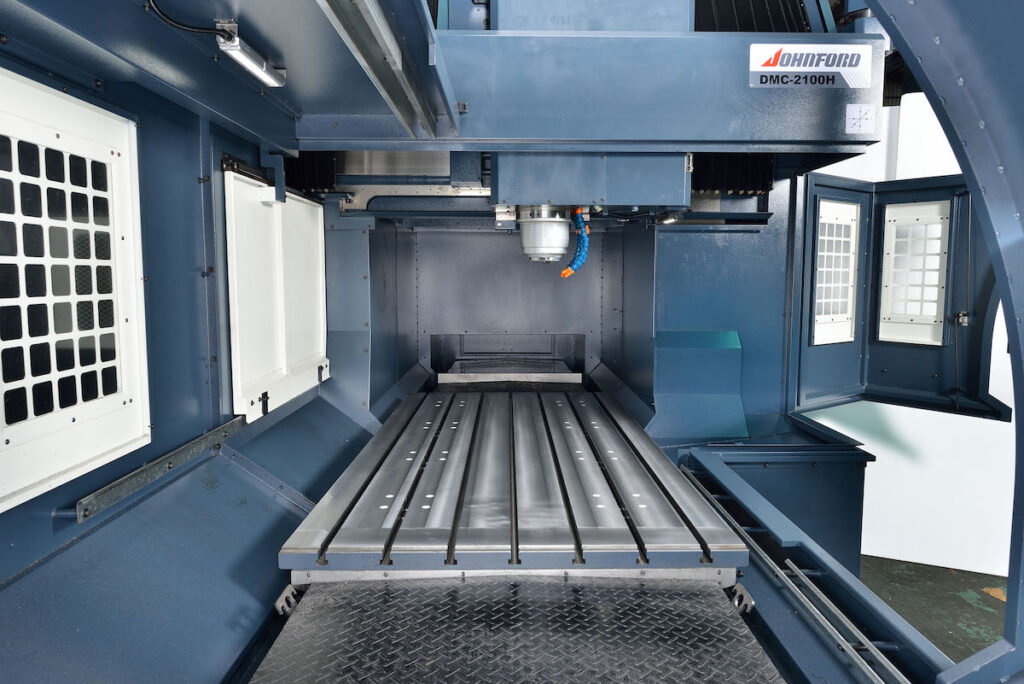

Engineered for Operator Efficiency and Safety

The DMC-1600 ~ 6100 series prioritizes ergonomics and accessibility, featuring 100% full machine enclosures to contain chips and coolant while providing excellent operator access from all sides. Swing-open side doors and a movable control panel simplify tool changes and machine setup, while the low 30.7″ table height ensures comfortable part loading. Powerful spindle options — from high-torque 2-speed gearbox designs to high-speed direct-drive and integral motor configurations — offer the flexibility to handle everything from heavy cutting to precision finishing.

Key Features:

Ideal for:

Need a customized-size CNC Bridge Mill?

Johnford prides itself on offering countless customized sizes and payload designs in both DMC moving table / fixed column designs and SDMC sliding column / fixed table designs.

Get a Quote or Learn More

Ready to invest in one of the most rigid, heavy-duty bridge mills on the market?

Contact us today for pricing, demos, or expert advice.

Specifications

| Item / Model |

DMC-1600

Request a Quote |

DMC-1600H

Request a Quote |

DMC-2100

Request a Quote |

DMC-2100H

Request a Quote |

DMC-3100

Request a Quote |

DMC-3100H

Request a Quote |

DMC-4100

Request a Quote |

DMC-4100H

Request a Quote |

DMC-5100 Request a Quote | DMC-5100H Request a Quote | DMC-6100 Request a Quote | DMC-6100H Request a Quote |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

X Travel |

63″ |

63″ |

80.7″ |

80.7″ |

120″ |

120″ |

161.4″ |

161.4″ |

200.8″ |

200.8″ |

240.2″ |

240.2″ |

|

Y Travel |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

|

Z Travel |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

|

Distance Between Columns |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

51.2″ |

|

Table Size |

66.9″ x 43.3″ |

66.9″ x 43.3″ |

86.6″ x 43.3″ |

86.6″ x 43.3″ |

130″ x 43.3″ |

130″ x 43.3″ |

165.3″ x 45.3″ |

165.3″ x 45.3″ |

204.7″ x 45.3″ |

204.7″ x 45.3″ |

244″ x 45.3″ |

244″ x 45.3″ |

|

Table Size |

17,600 lbs. |

17,600 lbs. |

22,000 lbs. |

22,000 lbs. | ||||||||

|

Table Load |

13,200 lbs. |

13,200 lbs. |

13,200 lbs. |

13,200 lbs. |

13,200 lbs. |

13,200 lbs. |

13,200 lbs. |

13,200 lbs. |

17,600 lbs. |

17,600 lbs. |

22,000 lbs. |

22,000 lbs. |

|

Rapids X/Y/Z |

590/590/472 BT-40/CAT-40 |

540/540/472 BT-50/CAT-50 |

590/590/472 BT-40/CAT-40 |

540/540/472 BT-50/CAT-50 |

590/590/472 BT-40/CAT-40 |

540/540/472 BT-50/CAT-50 |

590/590/472 BT-40/CAT-40 |

540/540/472 BT-50/CAT-50 |

590/590/472 BT-40/CAT-40 |

540/540/472 BT-50/CAT-50 |

590/590/472 BT-40/CAT-40 |

540/540/472 BT-50/CAT-50 |

|

CNC Control |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

|

Spindle Taper |

BT-40 / CAT-40 |

BT-50 / CAT-50 |

BT-40 / CAT-40 |

BT-50 / CAT-50 |

BT-40 / CAT-40 |

BT-50 / CAT-50 |

BT-40 / CAT-40 |

BT-50 / CAT-50 |

BT-40 / CAT-40 |

BT-40 / CAT-40 |

BT-50 / CAT-50 | |

|

Spindle RPM (BT/CAT) |

10,000 (15,000 DD opt.) |

6,000 (8,000 / 10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000 / 10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000 / 10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000 / 10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000 / 10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000 / 10,000 opt.) |

|

Spindle Motor |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

|

Spindle Drive |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

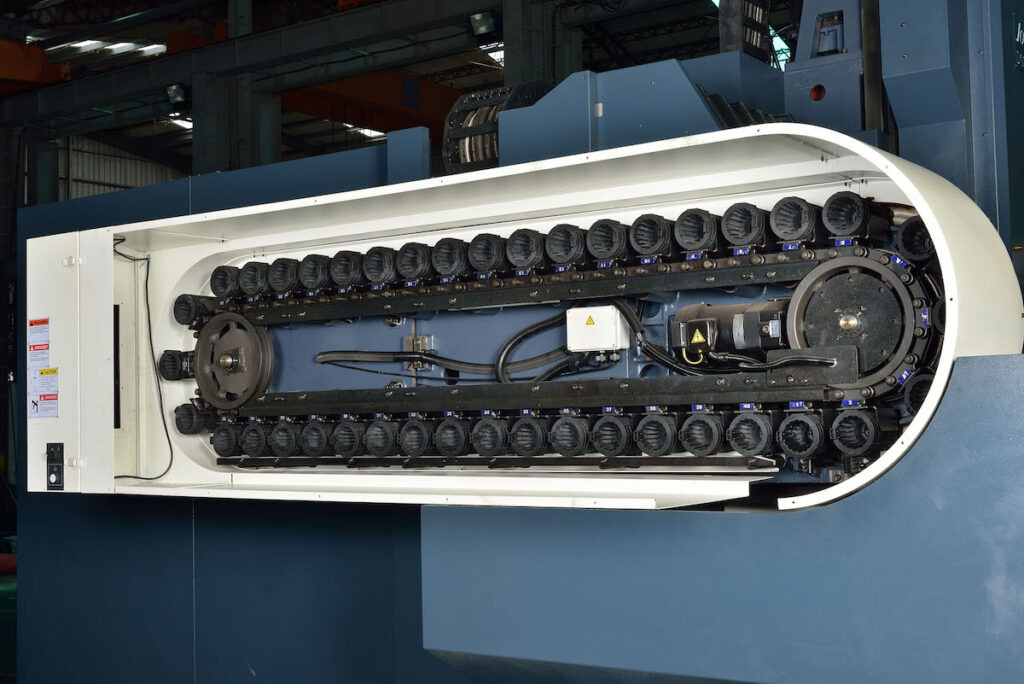

ATC Capacity |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

|

Weight |

45,000 lbs. |

45,000 lbs. |

52,000 lbs. |

52,000 lbs. |

59,000 lbs. |

59,000 lbs. |

66,370 lbs. |

66,370 lbs. |

73,788 lbs. |

73,788 lbs. |

91,483 lbs. |

91,483 lbs. |