5-Axis CNC

Machines

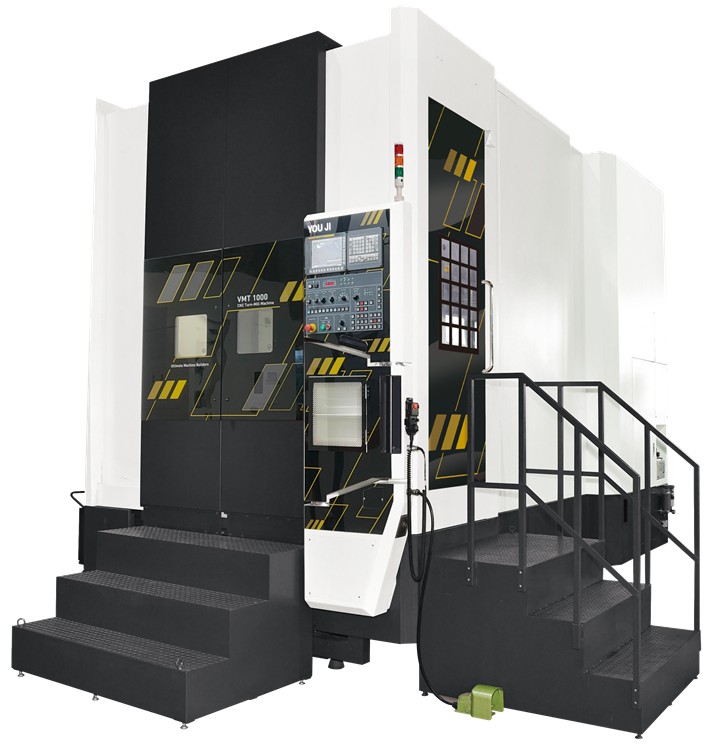

5-Axis CNC Machines

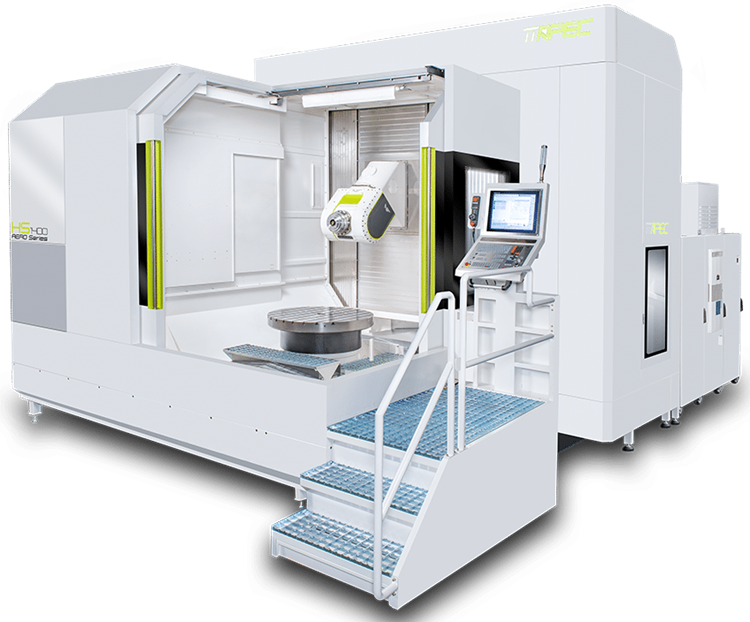

Need 5-Axis CNC machines? Look no further! We have some of the industry’s largest and most diverse 5-Axis CNC machine tools for applications in the aerospace, automotive, construction, agriculture and energy industries. Absolute carries a vast array of 5-Axis CNC machines. Johnford 5-axis sliding table machines are built heavy duty with box ways.

Take the time to browse our products below and review the specifications to see which 5-axis CNC machining center suits your needs best, then request a quote.

Machines

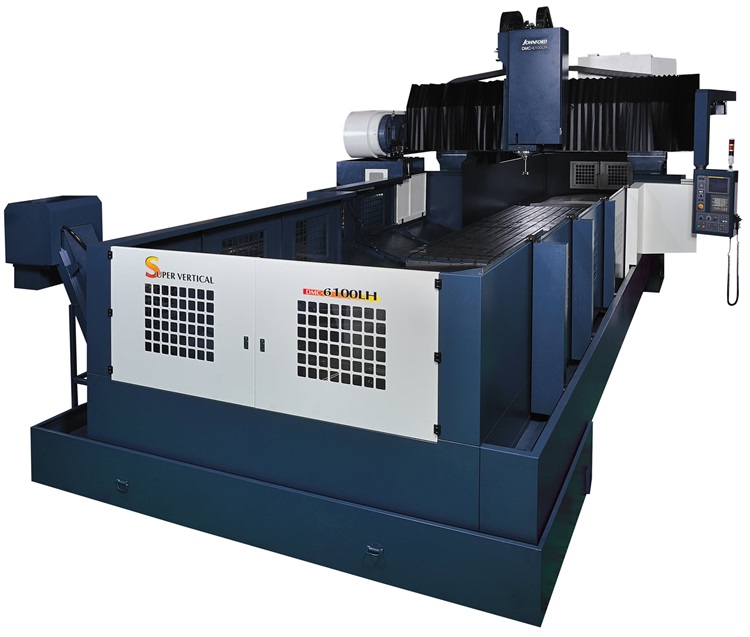

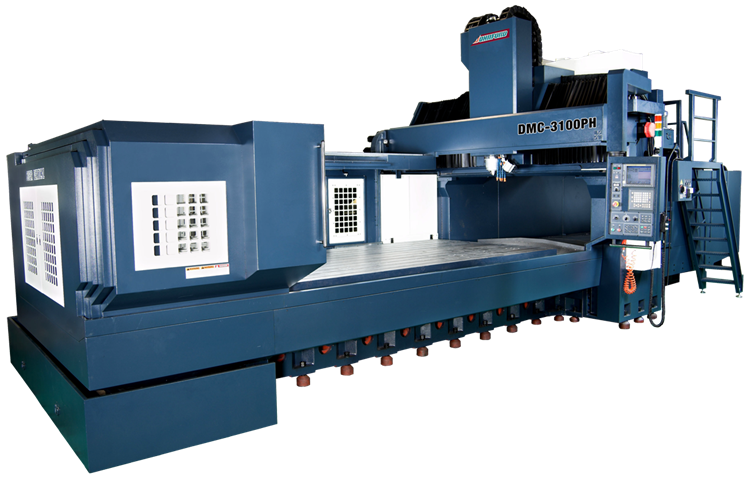

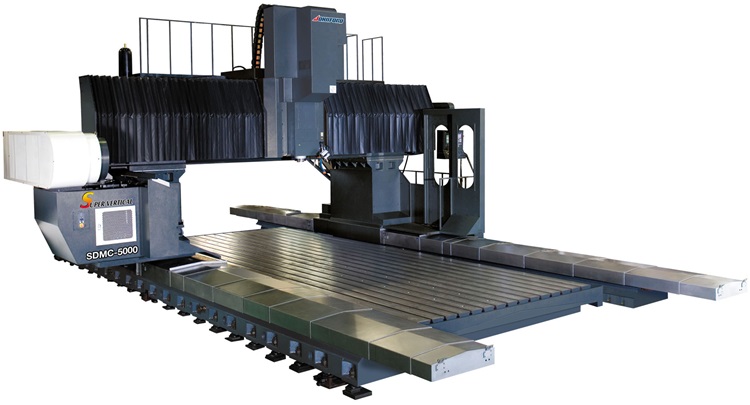

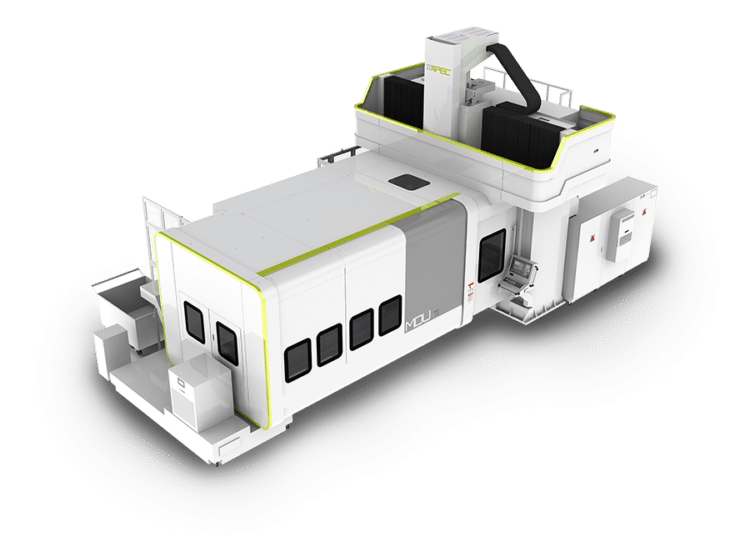

Johnford Massive Fixed or Moving Table/Fixed Column Bridge Mills

5-Sided/5-Axis Options for Specific Johnford DMC Models

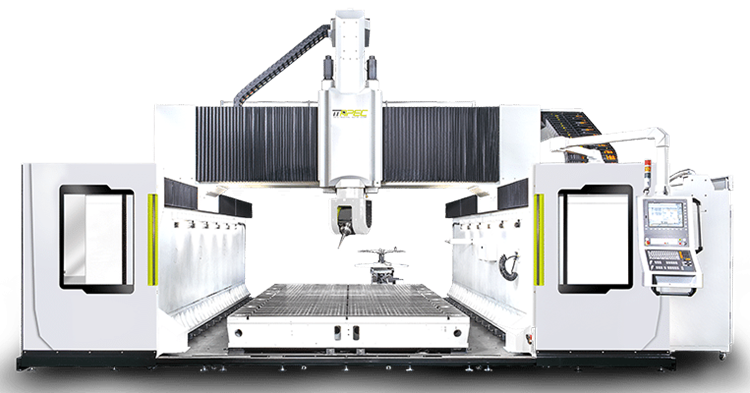

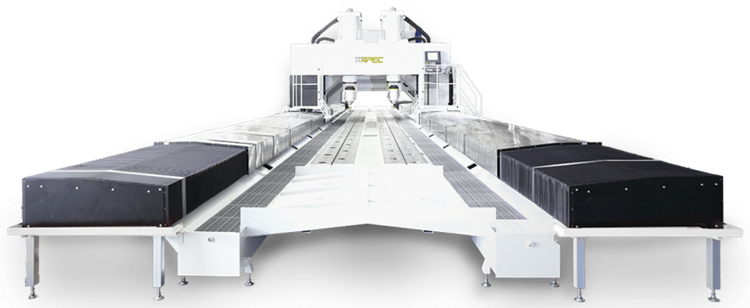

5-Axis Large Format High Speed Gantry Machining Centers for Aerospace & Injection Molds

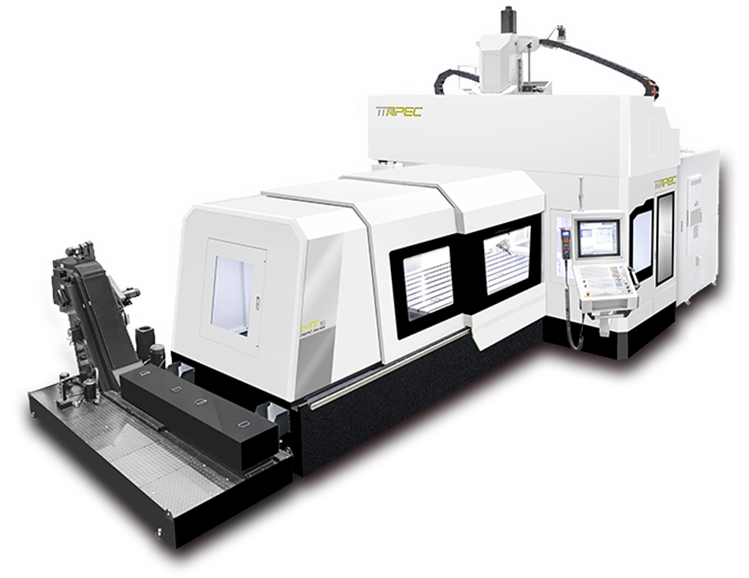

T8 Compact (2-Axis), T8 Mill (3-Axis), T8 Twin Y Mill (6-Axis) with Turret, and HYBRID (9-Axis) Twin Spindle Mill with Turret & B-Axis

More about 5-Axis CNC Machines

5-axis machining refers to the use of a CNC machine that is capable of moving a part or a cutting tool on five different axes simultaneously. A 3-axis CNC machine will move the part being machined in two axes — X and Y, while the tool moves along the Z axis (up and down).

With a CNC 5-axis machining center, two axes are added to the equation, allowing the tool to machine the part from multiple directions and angles.

Benefits of CNC 5-Axis Machining Centers

While 5-axis machining centers are a more costly investment than a 3-axis machine, the benefits can put that added cost into perspective. Key benefits of utilizing a 5-axis CNC machine include:

- Machine Complex Parts in a Single Setup: 5-axis machining allows for 2 additional axes to cut arcs and angles without additional setup or manual movement to reposition a part on the fixture.

- Faster Lead Times: Utilizing a 5-axis CNC machine allows for less manual “hands on” when operators reposition a part, as is typically done on 3 axis or 3+2 axis CNC machines. This saves a significant amount of time and allows for jobs to be done faster and more efficiently.

- Improved Part Accuracy: 5-axis machining removes the additional steps to reposition the part for 4th and 5th axis cutting and consequently reduces the risk of error or scrapping the part altogether.

- Improved Surface Finish: With 5-axis machining, the parts being machined are closer to the cutting tool, so there is less vibration when machining, which helps achieve a superior surface finish.

- Broaden a Shop’s Capabilities: As mentioned above, 5-axis machining allows for increased accuracy and higher throughput, allowing a manufacturer to enter into additional industries such as aerospace and defense.

- Longer Tool Life: With 5-axis CNC machines, the head of the machine is closer to the part, thus you use shorter tools that have less vibration than longer tools typically do. Through the use of shorter tools, a part can be cut at higher speeds, reducing vibration and allowing for longer tooling life.

- Better Investment and ROI: 5-axis CNC machines can be expensive, but as the technology continues to improve and CNC machine footprints become smaller, they also become more affordable.

- SAVE MONEY! 5-axis machining reduces part set-up times; improves tool life; produces more accurate parts; reduces floor space by having all 5 axes on one machine instead of having multiple machines taking up precious floor space; increases flexibility and spindle usage by being able to put more complex jobs on one machine; and decreases the need for costly fixtures to hold parts at various angles.

The overall takeaway is that a 5-axis CNC machine can allow your job shop to machine better, more accurate parts in less time with less wear on your machine. This all adds up to HIGHER PROFIT MARGINS for your operation.

Learn more about 5-axis CNC machines and how they can help you take your machining to the next level. Contact Absolute Machine Tools today at sales@absolutemachine.com.