OB7 Family of Cobots from Productive Robotics

Absolute Machine Tools is proud to distribute and service OB7 Cobots from Productive Robotics, which formed in 2010 and focuses exclusively on designing and manufacturing Collaborative Robotic Systems. These smart true independent 7-axis collaborative robots use a “no programming” simple teaching platform. Simply show OB7 how to do the job and OB7 quickly learns.

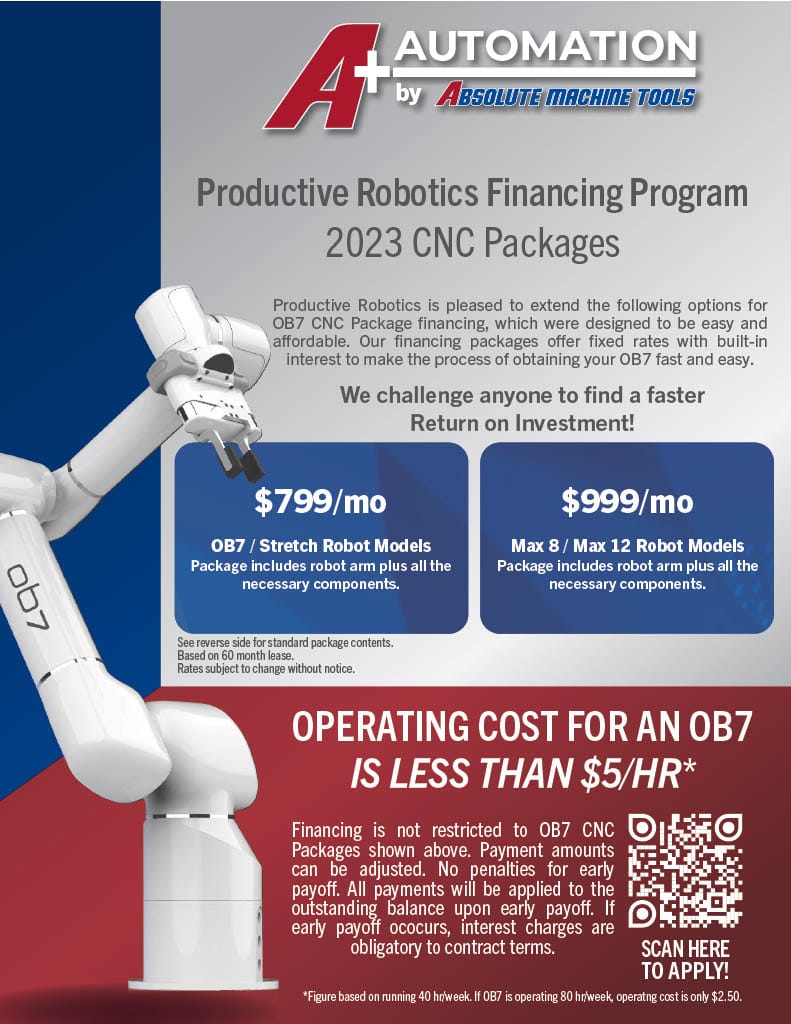

for Stretch & OB7

for Max 8 & Max 12

- Works 24 hours / 7 days a week

- Maximizes machine utilization and up time.

- Addresses labor and skills shortages.

- Enables re-shoring of production.

- No high integration costs.

- Learns jobs quickly & remembers them for next time.

- OB7 works with any Machining Centers, Turning Centers & other machines.

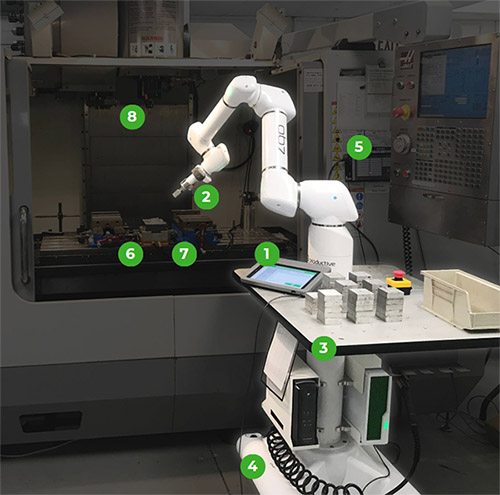

The moment OB7 is delivered to your door, you have all the equipment needed to connect to your CNC machine. OB7’s simple setup and minimal integration requirements make it the most cost-effective solution for machine shops.

The 7th axis gives OB7 ultimate flexibility and dexterity to reach around objects or obstacles. This eliminates having to position the OB7 in front of the machine’s door and blocking both the work area and the operator. Each of OB7’s joints can rotate 360° in both directions allowing the cobots to work in more confined work spaces and areas.

OB7 Cobots integrate quickly and seamlessly into your existing operations, easily adding new automation possibilities to your existing production lines or machines. These cobots are simple to set up with minimal learning time. They can handle small or large batch jobs and work safely without guarding. OB7 Cobots also reduce Bureau of Workers’ Compensation injury claims by helping to eliminate “continuous repetitive motions” that often affect employees.

Learn more about the benefits of OB7 Cobots and allow us to show you a real ROI by contacting Absolute Machine Tools at sales@absolutemachine.com!