Nexturn SA(B) 7-Axis Swiss Lathe Series

Click here for Special Offers

Buy a Nexturn SA-B Series Swiss Lathe & get a

FREE Bar Feeder

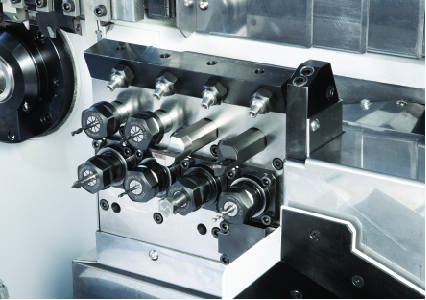

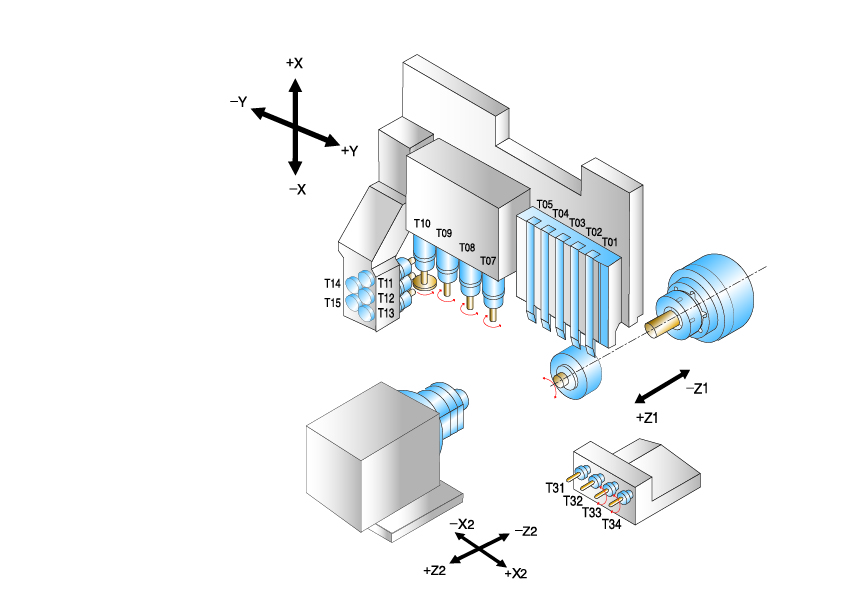

Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm. Maximum turning lengths are 6.3″ on the 12mm machine and 8″ on the 20mm and 32mm models.

Built-in motor on main spindles range from 3 – 10 HP and maximum RPM capacity up to 10,000 RPMs, while sub-spindles offer 1.5 – 3 HP and up to at 10,000 RPMs. Both spindles have full C-axis with .001° positioning. Powerful live tools, operating at 1.3 HP and 6,000 RPMs allow for complex milling operations.

Excellent rigidity results from the use of FEA technology in the one-piece bed casting design. The machine design maximizes ease of use with ergonomically arranged controls and fully opening covers and doors.

Specifications

| Item / Model |

SA-12B

Request a Quote |

SA-20B

Request a Quote |

SA-32B

Request a Quote |

|---|---|---|---|

|

FREE TRACER Minibar Bar Feeder Package |

FREE TRACER 20 Bar Feeder Package |

FREE TRACER 32V Bar Feeder Package | |

|

Number of Axes |

7 |

7 |

7 |

|

Number of Channels |

2 |

2 |

2 |

|

Bar Capacity (Front/Rear) |

12 mm / 12 mm |

20 mm / 20 mm |

32 mm / 32 mm |

|

Guide Bushing Type |

Synchronous |

Synchronous |

Synchronous |

|

Main Spindle |

3 HP |

5 HP |

10 HP |

|

Main Spindle |

10,000 RPM |

8,000 RPM |

8,000 RPM |

|

Sub Spindle |

1.5 HP |

3 HP |

3 HP |

|

Sub Spindle |

10,000 RPM |

8,000 RPM |

8,000 RPM |

|

Max. Turn Length |

6.3″ |

8″ |

8″ |

|

Total Tools |

18 |

22 |

20 |

|

Fixed Tools (Front/Rear) |

10 / 2 |

12 / 2 |

10 / 2 |

|

Live Tools (Front/Rear) |

4 / 2 |

6 / 2 |

6 / 2 |

|

Live Tools |

6,000 RPM |

6,000 RPM |

6,000 RPM |

|

Live Tools |

1.3 HP |

1.3 HP |

1.3 HP |

|

B Axis |

– |

– |

– |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC OiTF |

FANUC OiTF |

FANUC OiTF |

|

Weight |

4,180 lbs. |

5,940 lbs. |

6.820 lbs. |

Videos

FAQs

How are CNC Swiss lathes different from conventional lathes?

The difference between a CNC Swiss lathe and a conventional lathe is the utilization of the guide bushing. In Swiss lathes, the guide bushing gives support to the workpiece and allows for greater precision throughout the entire cutting process. Because the guide bushing holds the workpiece so close to the tool, there is essentially zero deflection due to the cutting force. With conventional lathes, stability for the part being turned decreases the further away the cutting tool is from where the machining material is being held by the chuck. This tends to result in chatter, vibration, whipping, and poorer surface finish quality. Swiss machines cut very close to the guide bushing on the main spindle side, is typically 0.20” (or 20 thousandths). This helps keep the piece extremely rigid, which makes a high quality surface finish achievable.

Why is the Swiss machine tooling capacity significant?

CNC Swiss machines can accommodate 20 or more tools in the tool zone, many with live tooling. Combined with a sub-spindle and backworking stations, this array of tools means Swiss machines can often produce finished, ready-to-ship components, eliminating the need for secondary operations on complex parts.

What is Servo Learning Oscillation on a CNC Swiss Lathe?

During the machining process, chips tend to pile up around the part or the tool. This can destroy the cutting tool or cause scratches to the outside finish of the part. Both are obviously undesirable outcomes that can be alleviated by the Servo Learning Oscillation feature on Nexturn Swiss CNC lathes. Servo Learning Oscillation constantly changes frequencies through the X, Y, and Z axes. Combining this with interrupting cutting on the part means the chips cleanly break away (hence the phrase “Breaking the Chip”) rather than allowing long stringy chips to gather around the part and cutting tool. The Servo Learning Oscillation feature is ideal for materials such as aluminum or stainless steel.