QuickTECH

Quicktech Multi-Axis, Multi-Spindle Mill-Turn Centers

For more than 25 years, Quicktech Machinery, a division of Tongtai, has built a global reputation for precision, innovation, and performance. As the former Hitachi Seiki OEM, Quicktech combines Japanese engineering heritage with advanced Taiwanese manufacturing to produce compact, high-productivity CNC mill-turn centers designed for today’s competitive manufacturing environments.

Quicktech’s advanced multi-axis designs integrate turning, milling, and drilling in a single setup for complete parts in one cycle. With up to 56 total tools and 24 B-axis live tools, these machines perform simultaneous operations on main and sub-spindles, reducing setups, improving accuracy, and cutting cycle times dramatically.

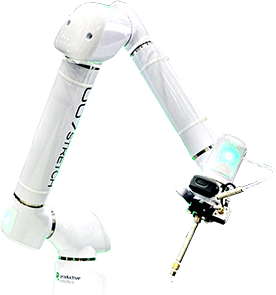

At the top of the Quicktech lineup are the T8 Hybrid, i-Ultimate, and Robo Series — each representing a leap in intelligent multi-process machining. The T8 Hybrid combines turret and B-axis technology for unmatched versatility; the i-Ultimate Series features dual B-axes and twin spindles for true 10-axis simultaneous machining; and the Robo Series integrates a 6-axis robot for fully automated part handling and lights-out production. Together, they offer high-end capability at a fraction of the cost of comparable European or Japanese models.

To support uninterrupted, lights-out production, every Quicktech mill-turn center sold by Absolute Machine Tools is packaged with a matching FREE hydrodynamic magazine bar feeder—available in 12′, 10′, and 6′ lengths—and compatible bar loaders in 4′, 5′, and 6′ configurations. Together, these systems deliver seamless automation for high-volume, continuous production.

Absolute Machine Tools is the exclusive distributor of Quicktech Machinery in North America, providing full sales, applications, service, and turnkey engineering support.

High Precision, High Production CNC Mill-Turn Centers

| i-ULTIMATE | The i-42 and i-60 ULTIMATE feature unique bar processing capabilities and complete parts machining, including all complex milling functions. |

| i-ROBO | The i-42 and i-60 ROBO machines feature an integrated 6-axis high speed Mitsubishi S-series robot that can load, unload, and turn parts over automatically. |

| i-TWIN | The i-42 and i-60 TWIN unique bar processing machines offer complete parts machining, including all complex milling functions. |

| i-ECO | The i-42 and i-60 ECO machines offer mass-production capabilities in a cost-effective design, providing single operation parts machining with all complex milling functions. |

| S-ATM | S-ATM series mill-turn centers feature 9 total axes, 2 turning spindles, a B-axis milling spindle with 24 tool auto tool change, and 6 fixed sub-spindle turning tools for a total capacity of 30 tools. |

| T8 SERIES | The T8 Compact is a 2-axis turning center with a 12-station BMT-55 turret, the T8 Mill adds live tooling and a full C-axis for true 3-axis capability, and the T8 Twin-Y features twin spindles and a Y-axis live turret for full 6-axis simultaneous machining |

| T8 HYBRID | The T8 HYBRID 9-axis twin spindle CNC mill-turn center comes standard with 2 turning spindles, 2 live milling spindles, B-axis, and a minimum capacity of 38 tools. This series also includes the T8 COMPACT (2-axis), T8 MILL (3-axis), and T8 TWIN Y (6-axis with turret) |

| T6 SERIES | The T6 COMPACT (2-axis) and T6 MILL (3-axis) combine a powerful 15 HP, 1.65” bar capacity main spindle with a tailstock for economical turning or mill-turn applications. |

Embracing Automation

Our A+ Automation team offers simple and affordable solutions for CNC machine automation

Machines

T8 Compact (2-Axis), T8 Mill (3-Axis) & T8 Twin Y (6-Axis) Mill-Turn Centers with Turrets