Nexturn SA(XII) 9-Axis with Opt. B-Axis Swiss Lathe Series

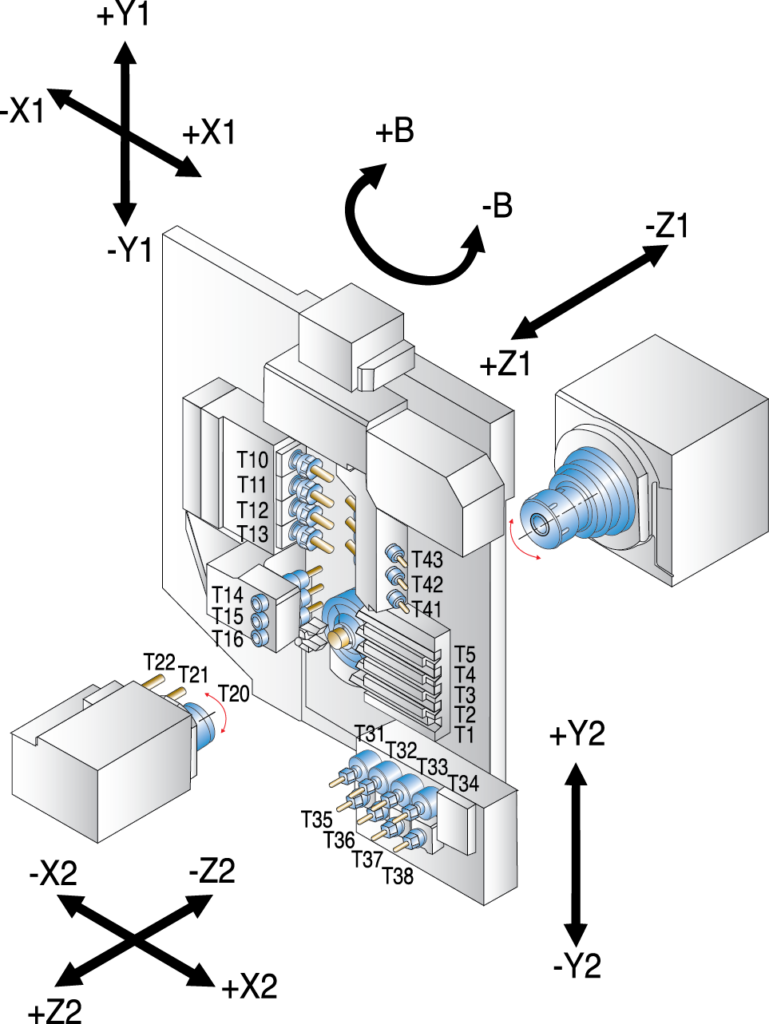

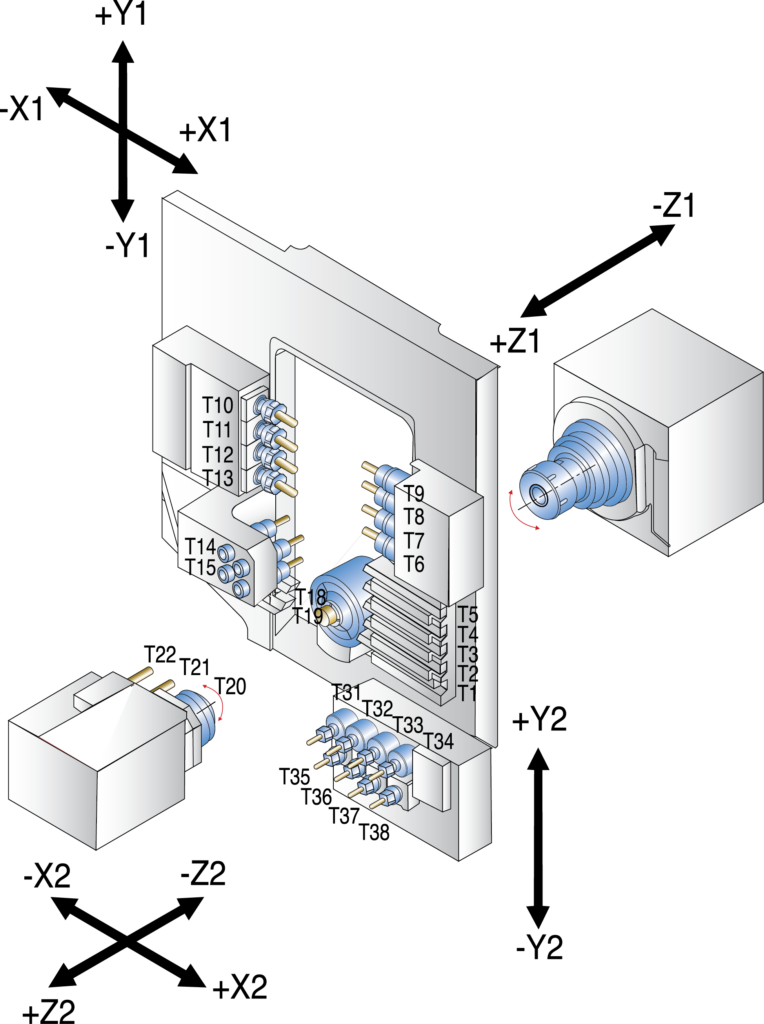

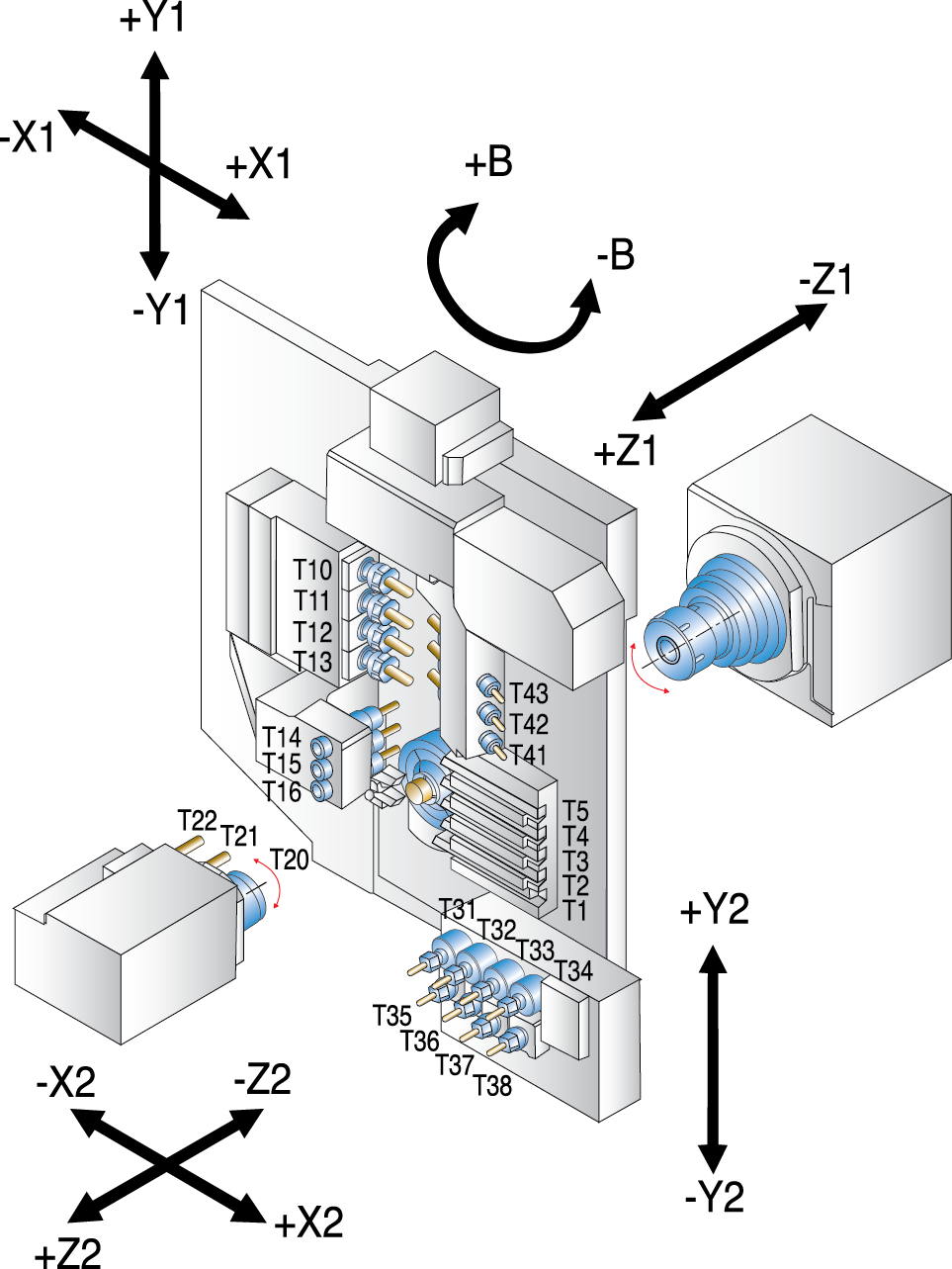

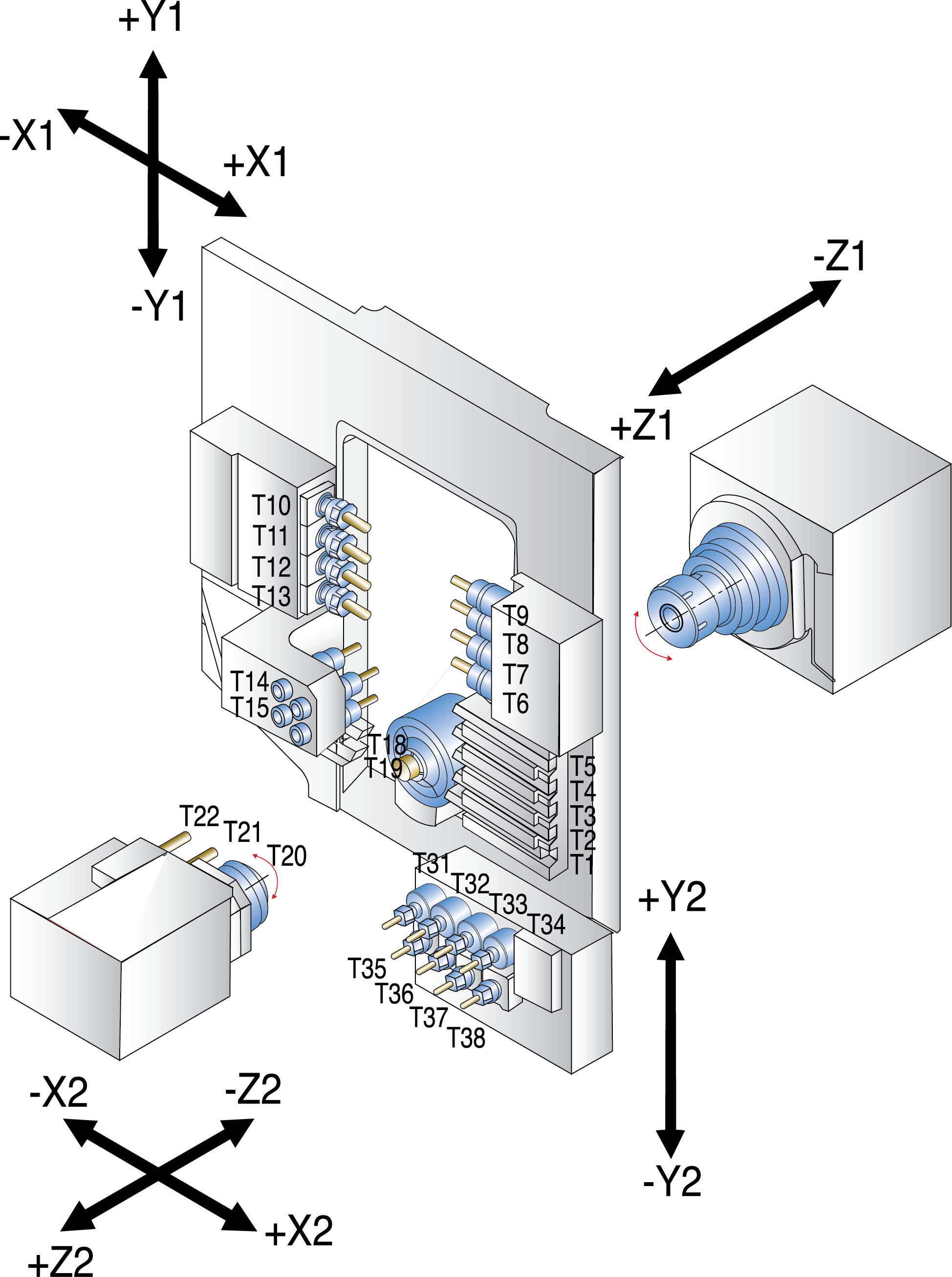

The SA(XII) series of Nexturn Swiss CNC lathes consists of five models with or without rotary synchronous guide bushings. An optional continuous swiveling 135˚ B-axis permits variable angle machining up to 10 front and 8 back-side live tools. Use of guide bushings permits turning of longer parts, while machines without guide bushings are ideal for processing short parts and cold drawn material.

The machines feature up to 8 axes and up to 29 total tools, increasing to 9 axes with the B-axis. Maximum bar diameter capacity of the main and sub spindles is 20mm – 51mm, depending on machine size. Maximum turning lengths are 118 mm – 275mm.

Main and sub spindles provide as much as 20 HP (15kW) at speeds as high as 8,000 RPM while offering full C-axis capability. The synchronous sub-spindle permits simultaneous front and back working. Live tools provide 1.3 HP (1 kW) – 3 HP (3.3 kW) and 6,000 RPM. Rigid tapping is standard.

Excellent rigidity results from the use of FEA technology in machine structure design. The slant-bed machines maximize ease of use with ergonomically arranged controls and fully opening covers and doors.

Specifications

| Item / Model |

SA-20XII

Request a Quote |

SA-32XII

Request a Quote |

SA-51XII

Request a Quote |

|---|---|---|---|

|

FREE TRACER 20 Bar Feeder |

FREE TRACER 32V Bar Feeder |

FREE TRACER 51V Bar Feeder | |

|

Number of Axes |

8 / 9 (opt.) |

8 / 9 (opt.) |

8 / 9 (opt.) |

|

Number of Channels |

2 |

2 |

2 |

|

Bar Capacity (Front/Rear) |

20 mm / 20 mm |

32 mm / 32 mm |

51 mm / 51 mm |

|

Max. Turn Length |

11″ |

11″ |

5.9″ |

|

Guide Bushing Type |

Synchronous |

Synchronous |

None |

|

Main Spindle |

5 HP / 10,000 RPM |

10 HP / 8,000 RPM |

17.5 HP / 6,000 RPM |

|

Sub Spindle |

3 HP / 8,000 RPM |

3 HP / 8,000 RPM |

20 HP / 6,000 RPM |

|

Total Tools |

31 / 29 |

31 / 29 |

22 |

|

Fixed Tools (Front/Rear) |

11 / 4 |

11 / 4 |

10 / 3 |

|

Live Tools (Front/Rear) |

12 / 10 |

12 / 10 |

6 |

|

Live Tools (Rear) |

4 |

4 |

3 |

|

Cross Live Tools |

1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

3 HP / 6,000 RPM |

|

Backend Live Tools |

1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

|

B Axis |

0 – 135º |

0 – 135º |

0 – 135º |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC 31iT |

FANUC 31iT |

FANUC 31iT |

|

Weight |

7,920 lbs. |

8,140 lbs. |

9,240 lbs. |

FAQs

How does a CNC Swiss machine work?

As the turning process begins on a CNC Swiss machine, the main spindle unchucks the workpiece, giving the operator the amount of stroke needed based on the length of the part. The guide bushing continues to feed material into the tooling to create the desired features. The close geometry construction of the machine allows the tool to work within millimeters of the workpiece, reducing chip-to-chip time to a second or less. Using a guide bushing allows a tool to take a heavier depth of cut on the part itself without jeopardizing tolerances. Then, the machine performs a pick off process with the sub-spindle side. If there are any secondary operations to be done on the back of the part, this can be achieved here at the sub. The part is then dropped into a conveyor, which ejects it out the front of the sub.

What is a guide bushing?

The rotary guide bushing, originally called an anti-friction guide bushing, was patented in 1963 to hold various diameters of bar stock for automatic screw machines. The guide bushing rotates the workpiece and pushes it into and out of the cutting tool. It was found to be particularly adaptable for use in a Swiss-type automatic screw machine, which are generally provided with a headstock movable axially to the machine frame while rotating the bar stock. Having an adjustable bushing allows for turning bar stock rigidly and close to the turning tools, which makes it possible to machine parts with high quality finishes and extreme accuracies. A rotary guide bushing rotates with the workpiece and is ideal for turning wider parts, with tolerances greater than +/-0.0005”. Fixed guide bushings remain stationary while the bar stock spins and are ideal for parts that require tighter tolerances.

How many axes does a Swiss lathe have?

While the number of axes can vary depending on the options, most conventional Swiss lathes have 7-9 axes. For instance, the Nexturn SA(XII) series feature up to 8 axes and up to 29 total tools, increasing to 9 axes with the B-axis.