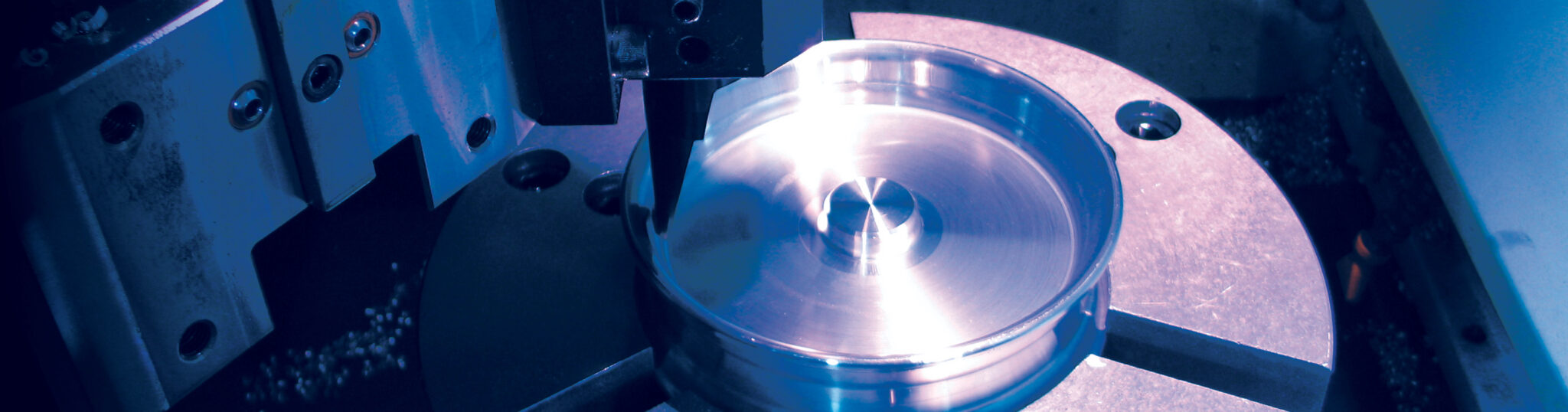

CNC Vertical Lathes & CNC Vertical Turning Centers

You Ji Vertical Turning Centers (VTCs) and Vertical Turning Lathes (VTLs) are heavy-duty CNC machine tools globally recognized for their solid, heavy-weight construction designed and engineered specifically for machining large, heavy, and often asymmetrical components. These machines are widely used across demanding industries such as aerospace, energy, transportation, and heavy equipment manufacturing. For applications beyond the capacities of their standard VTC and VTL lineup, You Ji offers customized machinery solutions, specifically designed, engineered, and built to meet unique and atypical requirements.

You Ji’s CNC Vertical Turning Centers are advanced multi-axis machines that offer exceptional versatility. Featuring live tooling and optional Y-axis capabilities, these machines enable complex milling, drilling, and tapping operations—all within a single setup. The vertical spindle orientation naturally supports heavy workpieces using gravity, while optional C-axis and Y-axis functionality allows for full contouring of intricate geometries. These machines are ideal for precision applications requiring both turning and milling processes. You Ji also offers vertical turning centers with standard CAPTO tooling systems and automatic pallet changer configurations, integrated horizontal side-head models for multitasking, extra large mill-turn centers, and 6-position vertical hex turret machines specifically for making large aluminum wheels or similar parts.

In contrast, You Ji CNC Vertical Turning Lathes are purpose-built for high-precision turning operations, particularly for large and oversized workpieces. Designed for straightforward turning tasks, these machines are available in single or dual ram configurations and can be equipped with various tool changer systems and grinding attachments to suit a wide range of production requirements.

Spindle Speed Variation to Disrupt Chatter and Achieve the Finest Finishes

Spindle Speed Variation (SSV) is a technique that periodically alters the spindle speed during cutting to disrupt the chatter that often occurs when machining at a constant speed. By breaking up harmonic resonance at the point of contact between the cutting tool and the workpiece, SSV helps achieve a smoother surface finish—without the need to reduce cutting parameters or spindle speed, thus maintaining high productivity. This feature is especially beneficial in deep boring or turning operations, as well as when machining long, slender workpieces or thin-walled parts that are prone to vibration.

SSV is a built-in feature on all FANUC Oi-TF Plus CNC controls, while FANUC Model B 16i, 18i, 21i, 30i, 31i, and 32i may require minor parameter configurations. Fanuc 15i, 20i, 160i, 180i, and 210i support SSV, but may be based on specific machine tool builder factory control configurations. Contact Absolute Machine Tools to learn more about integrating this feature to better enhance your company’s machining processes.

Eccentric Turning Operations

Unconventional turned parts — such as those with tapers, elliptical shapes, or varying radii—are ideally machined using Eccentric Turning (EC), a powerful feature from FANUC. Eccentric Turning enables precise machining of off-center workpieces, making it an excellent solution for components like cams, pins, threads, tapers, and other non-circular geometries. It offers outstanding accuracy and significantly reduces setup time.

Custom workholding is required for Eccentric Turning. This typically involves offset chuck jaws or specially designed chucks and faceplates with adjustable offsets to securely hold the part away from the main spindle centerline. For optimal performance, Eccentric Turning should be used in conjunction with Spindle Speed Variation (SSV). Together, these features help control vibration, reduce tool and spindle wear, and improve surface finish quality — especially on unbalanced or asymmetrical parts.

Even on machines without a Y-axis, EC can still be implemented, expanding its applicability across a wide range of turning platforms. Additionally, certain eccentric features can be machined using live tooling and milling operations, offering even greater flexibility.

You Ji’s vertical turning centers and lathes, available in both single and dual ram configurations, are equipped with advanced features like Eccentric Turning and Spindle Speed Variation. When paired with live tooling and Y-axis capabilities, these machines deliver exceptional versatility and performance — setting them apart from most CNC systems available today.

Contact Absolute Machine Tools to learn more about how You Ji machines can elevate your turning operations.

Vertical Turning Centers (VTCs)

Vertical Turning Lathes (VTLs)

What Advantages Are There to Using Automation with These Machines?

Automation allows for strategic advantages such as continuous operations, unattended overnight or weekend runs, and automated loading/unloading of parts. Adding a robotic arm or gantry loader allows for faster performance and more accurate repeatability, less handling and manual labor, consistent loading and unloading, reduced downtime, part probing, and addresses skilled labor shortages, especially in high-mix, low volume environments. Another advantage that automation offers is that one operator can then manage multiple VTCs or VTLs at a time, allowing for less hourly costs per job and increased profitability.

The TERMS Vertical Turning Center and Vertical Turning Lathe are often used interchangeably, but there are key differences. These machines may look similar and share some overlapping features, but serve different roles based on complexity, capability, and flexibility as they relate to different machining applications.

Vertical Turning Center (Complex Multi-Axis Turning & Milling Use) | Vertical Turning Lathe (High-Volume Simpler Turning Use) |

|---|---|

CNC machine often fully enclosed and used for turning, milling, drilling, tapping and other advanced capabilities such as Y-axis and C-axis capabilities for full contouring. | CNC machine designed primarily for turning large heavy-duty workpieces. |

Equipped with live tooling, automatic tool changers, C-axis for table rotation, and Y-axis for off-center milling and drilling. | Equipped with basic turning tools, turret-style tool changers, and optional attachments like grinding heads. |

Used for complex parts that require multiple operations in a single setup, thereby reducing changeover time and increasing accuracy necessary for aerospace, energy, and defense applications. | Used for simpler or repetitive turning tasks especially when milling is not required, and common for industries machining flanges, rings, and brake drums. |

Machine configuration is more advanced to support the demands of multi-axis machining. | Machine configuration is often single or dual column construction with a vertical ram for simpler setups. |

For nearly 50 years, You Ji has been a world-renowned leader of large customized CNC machine tools. Most notable are their vertical turning center and vertical turning lathes, however, the company also has a diverse lineup of vertical machining centers, table-type and floor-type boring mills, duplex machining centers, bridge mills, travelling column drilling and tapping centers, flat bed horizontal lathes, and horizontal turning centers.

Absolute has sold and installed thousands of You Ji vertical turning centers in the United States and around the world. Contact us today at sales@absolutemachinetools.com to learn more about our wide range of CNC lathes.