Our Current Machines In Stock

-

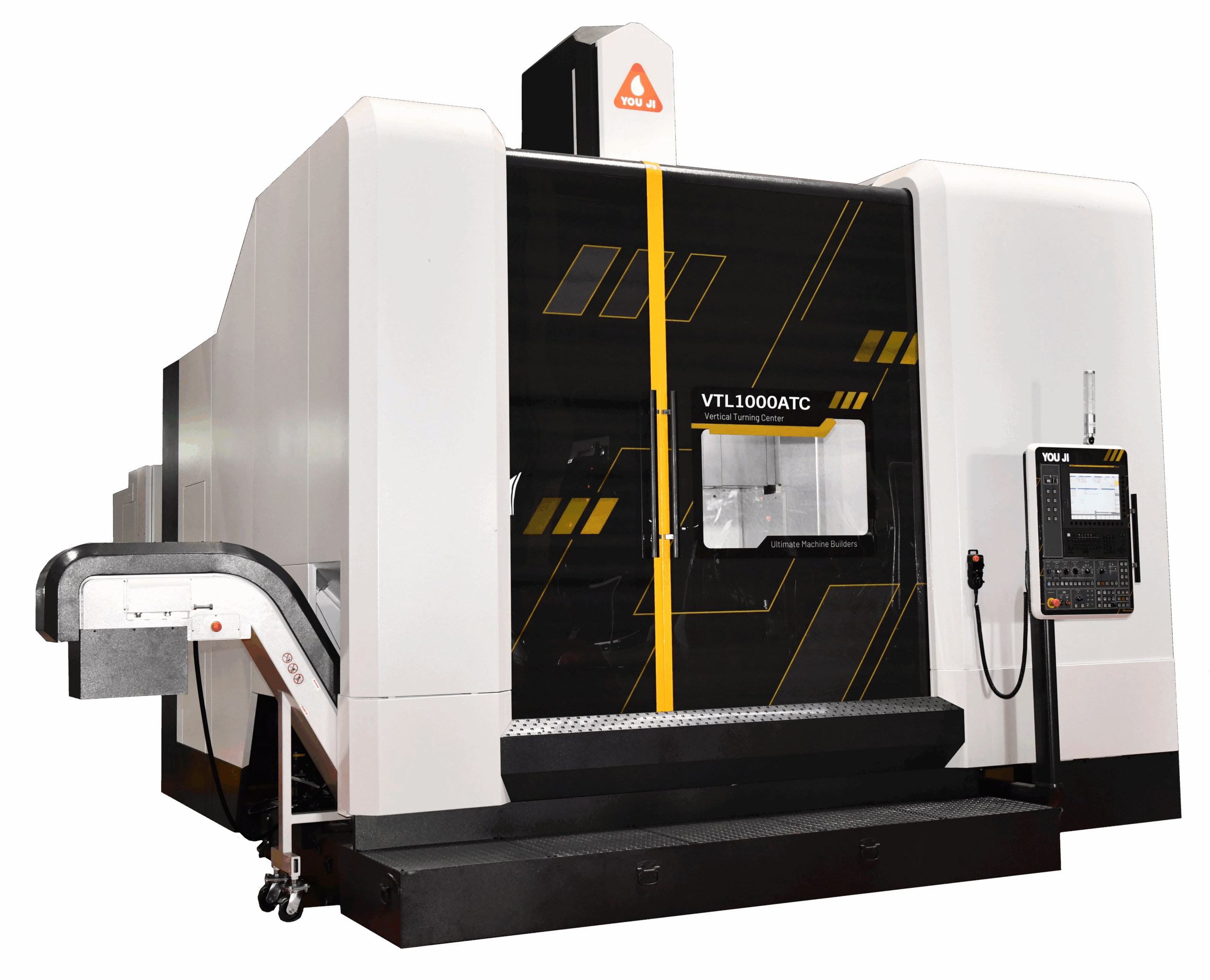

YV-800ATC Vertical Turret ATC Turning Center

-

VMT1000 Vertical Mill/Turn CenterBrand: You JiSerial #: 1VMT100TY09349

VMT1000+Y with Fanuc 31iTB PLUS w/ 15″ Color LCD and Manual Guide i, 40 Tool BT-50 Arm-type ATC, 32″ Hydraulic Chuck, High / Low Chuck Pressure, B-Axis Head: 5 degree index – 0-90 degrees, XYZ Axis Linear Scale, Chip Flush System, Auto Tool Setter, Auto Door with Light Curtain, 1000psi CTS, (2) Boring Bar, (2) Turning, (2) Facing, (1) Y-Axis RH, (1) Y-Axis LH