Mold & Die

Mold & Die Machining Solutions

Absolute Machine Tools delivers complete CNC solutions for the mold and die industry, built on six core technologies: 5-axis gantry-type machining centers, bridge mills, vertical turning lathes (VTLs), wire EDM, die sinkers, and deep hole drilling machines. These technologies form the backbone of modern mold and die manufacturing, providing rigidity, accuracy, and ultra-fine surface finishes. From oversized injection molds to intricate cavity work, Absolute helps shops reduce cycle times, extend tool life, and achieve unmatched precision.

Benefits for Mold & Die Manufacturers

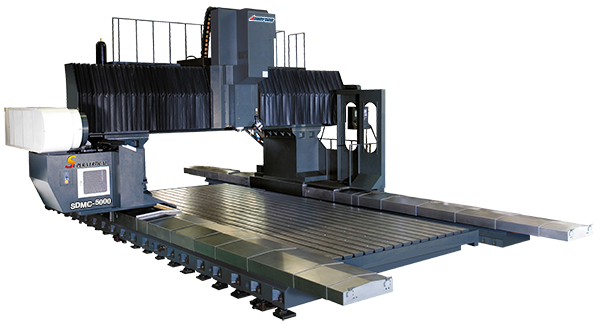

5-Axis Gantry-Type Machining Centers

APEC Gantry Mills (MT, MTH, GM, SK, SKM, HS series): High-speed, large-format 5-axis solutions for heavy roughing in tool steels and precision finishing of complex geometries.

Vertical Turning Lathes (VTLs)

You Ji Vertical Turning Lathes: Designed for large mold bases, round dies, and oversized components that require maximum stability and accuracy.

Deep Hole Drilling Machines

Precihole CNC Deep Hole Drilling Machines: Precision drilling of cooling channels, ejector pin holes, and long, straight bores in large molds.

AccuteX Hole Drilling EDM: Rapid starter holes for wire EDM and cooling channel operations.

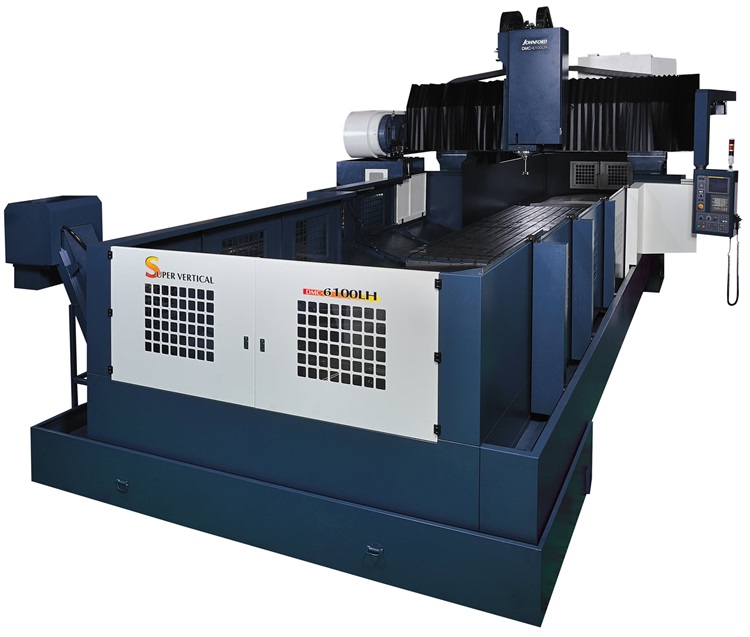

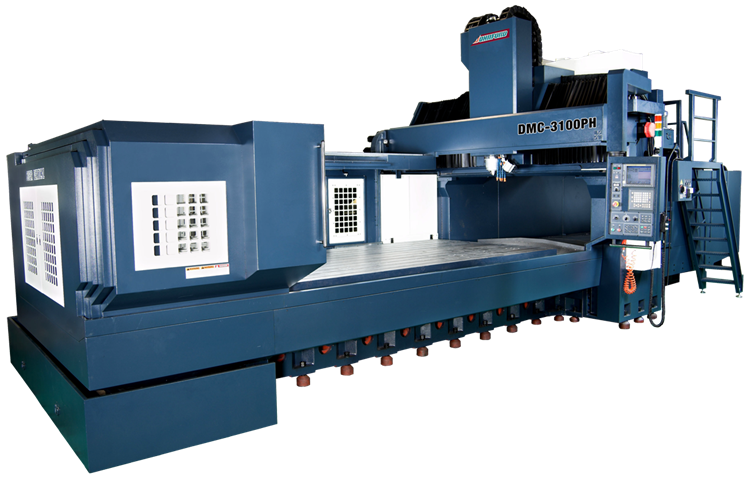

Bridge Mills

Johnford Double Column Bridge Mills (DMC Series): Rigid Meehanite castings, oversized tables, and 5-axis options for large molds and stamping dies.

Wire EDM

AccuteX Wire EDM Machines: High-speed cutting, advanced digital spark control, and automatic wire threading for mold inserts, cooling channels, and fine detail work.

Die Sinkers

AccuteX Die Sinking EDM: High-rigidity structures and advanced discharge control for cavity burning in hardened steels and superalloys with superior surface finishes.

Machines

Johnford Massive Fixed or Moving Table/Fixed Column Bridge Mills

5-Sided/5-Axis Options for Specific Johnford DMC Models

Ideal Mold & Die Applications

Why Absolute Machine Tools?

For decades, Absolute Machine Tools has provided CNC solutions that help moldmakers achieve net-shaped parts, reduce lead times, and boost profitability. With a comprehensive lineup of 5-axis gantry machining centers, bridge mills, VTLs, wire EDM, die sinkers, and deep hole drilling machines from trusted brands such as APEC, Johnford, You Ji, AccuteX, and Precihole, Absolute delivers the right technology to match your mold & die challenges.

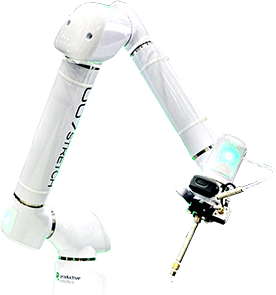

Revolutionize Your Workflow with Advanced Automation

Automation is the key to staying ahead in today’s competitive mold and die industry. Our A+ Automation Team specializes in integrating robotic automation solutions that seamlessly integrate into your manufacturing environment. By leveraging industrial and collaborative robotics, we empower you to achieve higher productivity, improved safety, and reduced downtime.

Let our expertise in robotics and automation help you streamline your operations and maximize your ROI

Take Your Die Mold Manufacturing to New Heights with Absolute Machine Tools

Ready to elevate your mold and die manufacturing processes to new heights? Partner with Absolute Machine Tools, the industry leader in providing top-notch machining solutions and advanced automation. Discover the difference that precision, efficiency, and reliability can make in your business. Request a quote today to explore our extensive range of products and services or contact our knowledgeable team to discuss your specific requirements. Together, we will shape a future of success for your mold and die operations.

Frequently Asked Questions

What is the die and mold industry?

The die/mold industry is a specialized sector involved in the manufacturing of molds, dies, and related components used for shaping and forming various materials, including metals, plastics, and composites.

What are molds and dies?

Molds are tools used to shape materials by injection molding, casting, or other processes. Dies, on the other hand, are tools used to cut, shape, or form materials through processes such as stamping or forging.

How are CNC machine tools used in the die/mold industry?

CNC machine tools play a critical role in the die/mold industry by precisely machining molds, dies, and related components. They enable complex shaping, drilling, milling, and cutting operations with high accuracy and efficiency.

What types of CNC machine tools are commonly used in the die/mold industry?

Common types of CNC machine tools used in the die/mold industry include CNC milling machines, CNC machining centers, CNC turning machines, EDM (Electrical Discharge Machining) machines, and grinding machines.

What are the advantages of using CNC machine tools in die/mold manufacturing?

CNC machine tools offer numerous advantages, including high precision, repeatability, and the ability to produce complex shapes and features. They improve productivity, reduce manual labor, and allow for faster production cycles.

What materials are commonly used in die/mold manufacturing?

Die/mold manufacturing works with a wide range of materials, including metals such as steel, aluminum, and copper alloys, as well as various types of plastics and composites.

How important is precision in die/mold manufacturing?

Precision is of utmost importance in die/mold manufacturing, as even minor deviations can affect the quality and functionality of the final product. Close tolerances and meticulous attention to detail are essential to meet industry standards and customer requirements.

What industries rely on die/mold manufacturing?

Die/mold manufacturing serves various industries, including automotive, aerospace, electronics, medical devices, consumer goods, packaging, and more.

How are molds and dies manufactured?

Molds and dies are typically manufactured using advanced machining techniques such as CNC milling, turning, and grinding. Additional processes such as EDM and wire cutting may also be employed.

Are CNC machine tools suitable for both small-scale and large-scale die/mold production?

Yes, CNC machine tools are highly versatile and can be used for both small-scale and large-scale production. They can handle single-piece prototypes as well as high-volume manufacturing.

How important is precision in CNC machining for die/mold manufacturing?

Precision is crucial in die/mold manufacturing, and CNC machine tools excel in delivering high levels of accuracy. They ensure consistent results, tight tolerances, and excellent surface finishes, meeting the demanding requirements of the industry.

Can CNC machine tools be integrated with other automation systems in the die/mold industry?

Yes, CNC machine tools can be integrated into automated production systems. They can be combined with robotic loaders, conveyor systems, and other automation technologies to streamline production and enhance efficiency.

How can CNC machine tools contribute to reducing lead times in die/mold manufacturing?

CNC machine tools offer faster setup times, rapid tool changes, and high-speed machining capabilities, all of which contribute to shorter lead times in die/mold manufacturing. Additionally, their precise and efficient operation minimizes the need for secondary operations, further reducing overall production time.

What are the challenges and needs in die and mold machining?

Die and mold machining involve long cycle times and single-piece applications of high-value workpieces. It requires maximum thermal stability, form accuracy, seamless blending, and optimum speed.

How does Absolute Machine Tools’ engineering and automation services address these challenges?

Our engineering and automation services aim to achieve unattended operation and reduced cycle times. We can help you create a stable process, capture unattended machining time, eliminate multiple setups and manual handling, and minimize the need to move parts between machines. Additionally, we can help you achieve a superior finish, eliminating the time-consuming step of hand polishing.

How does rigid machine construction benefit dynamic accuracy in die/mold machines?

Rigid machine construction provides stability and stiffness, minimizing vibrations and deflection during machining operations. This results in improved dynamic accuracy, better surface finishes, and enhanced overall performance of the die/mold machine.

OEMS

Johnford Bridge Mills, Boring Mills, & Large Lathes

Elevate your mold and die manufacturing with Johnford CNC machines. Engineered with cutting-edge technology, these machines deliver unparalleled precision and productivity. Whether it’s complex mold components or intricate die manufacturing, Johnford machines provide the accuracy needed for exceptional results. Built with robust construction and high-quality components, these machines are designed to withstand the demands of heavy-duty mold and die manufacturing. Their robust construction ensures durability and reliability, minimizing downtime and optimizing efficiency.

Seiki Multi-Axis, Multi-Spindle Mill-Turn Centers

Experience unparalleled accuracy as Seiki mill/drill/tap centers effortlessly handle a wide range of machining operations. From milling to drilling and tapping, these machines ensure precise execution, even for complex mold components and intricate dies.

Precihole Precision Deep Hole Drilling Machines

In the complex world of die and mold manufacturing, components often feature intricate shapes and require drilling holes at multiple angles. This not only demands exceptional operator skills but also increases process time. Enter Precihole machines, designed to cater to both large and small mold plates, revolutionizing the industry. Precihole’s 3-axis gun drilling machines are engineered to cater to the precise needs of prismatic parts that require multiple holes on the face. These cutting-edge machines are designed to drill angular holes in a wide range of components, including manifold plates, dies, capsule magazines, runner blocks, ejector pins, and more. With specially designed fixturing for specific components, cycle times are significantly reduced, optimizing productivity. In addition, Precihole provides column-type drilling machines specifically tailored for large mold bases and tube sheets. These machines can be easily configured to operate in either gun drilling mode or BTA mode, depending on the specific requirements of the application. The series of machines offers versatility with the option to incorporate 3 to 7 axes of CNC, allowing customization based on the desired features and functionalities.