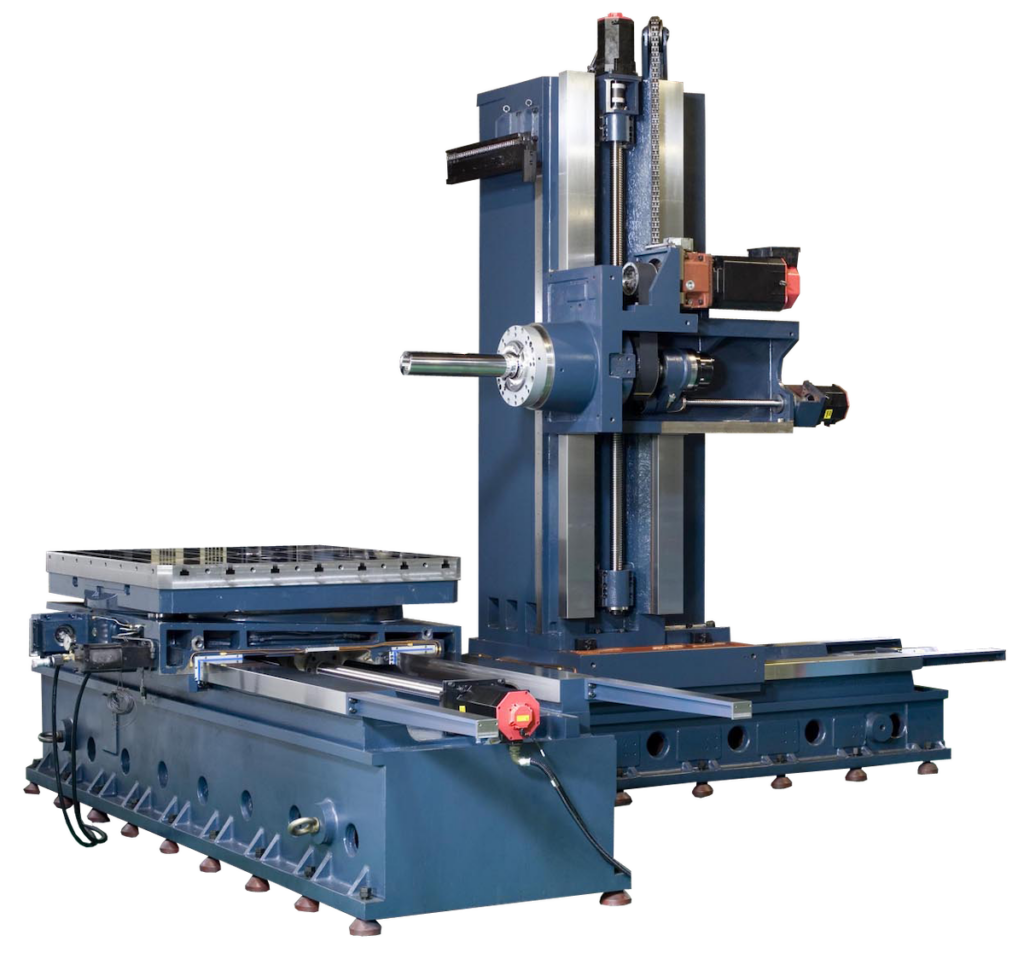

Johnford AHC-1600 Moving Column Table-Type Horizontal Machining Center

“Every job shop’s dream machine!” Tony Brandt, Brandt’s Custom Machining, Mansfield, Ohio

Combination Moving Column Table-Type Horizontal Machining Center

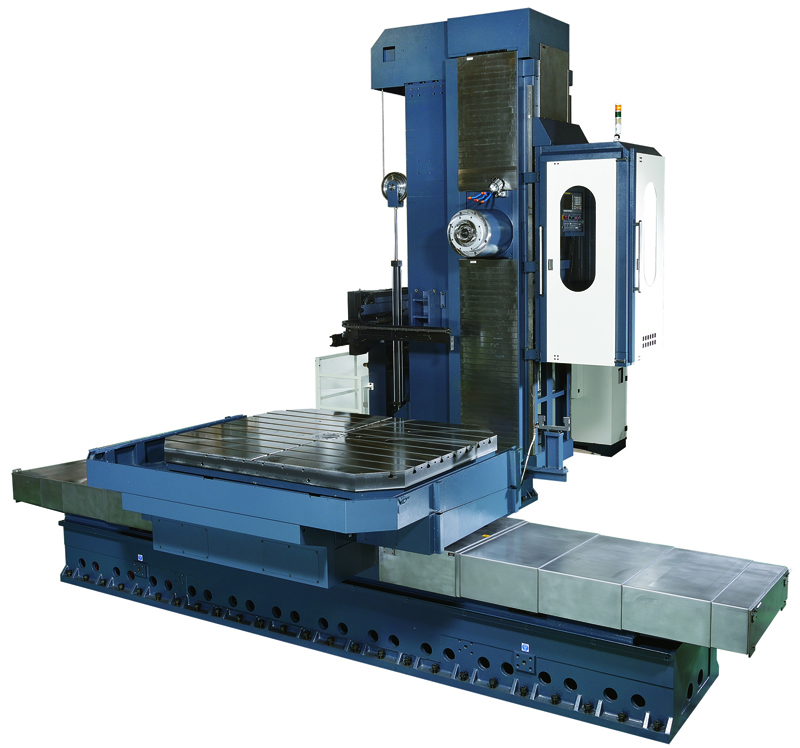

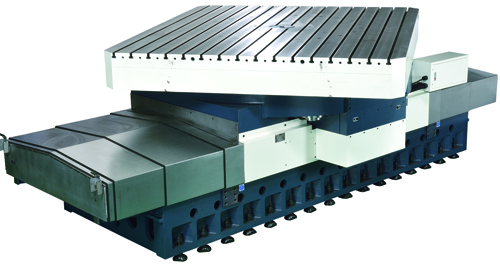

The Johnford AHC-1600 moving column table-type horizontal machining center is ideal for aerospace applications as well a wide variety of other industries. The machine features a moving column for the Z axis and a moving table for the X axis. The design provides maximum rigidity and accuracy as well as full support of the table over the complete X axis travel. The X axis is fully supported by the base with absolutely no overhang, eliminating any need for outriggers or outboard supports to handle high table loads. With standard accessories, the rigid Meehanite cast iron machining center weighs in at more than 40,000 lbs.

The AHC-1600 features precision-ground and induction-hardened box ways in the X, Y, and Z axes. All mating surfaces are coated with Turcite-B and hand scraped for fit. A pressurized automatic oil system force lubricates the ways. Large (2.0″/50 mm)-dia., pre-tensioned ballscrews and powerful servo motors achieve accurate positioning. Standard Heidenhain linear scales in all linear axes assure consistent accuracy.

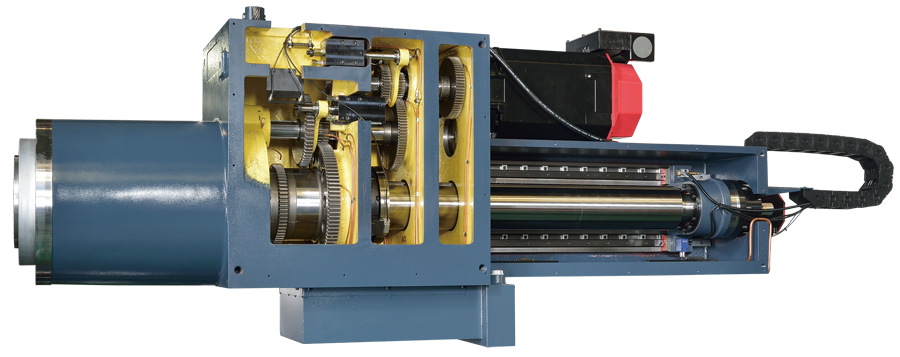

The standard 6,000 rpm 50-taper spindle has a 35 hp main motor and 2 speed gear drive. The spindle and gearbox are oil cooled for minimal thermal growth. Spindle options include 10,000 rpm direct drive 50-taper spindles and a high power 15,000 rpm HSK-100A spindle that provides 56 hp and 300 lb-ft of torque.

A stand-alone heavy-duty 40-tool arm-type automatic tool changer is standard, with 60, 80 and 120 tool capacity optional. Also standard is a comprehensive chip removal system, a high volume coolant system, full machine enclosure, and a combination 63″ x 32″ flat table with a built-in 800mm full B-axis rotary table. The standard Fanuc OiM-F Plus CNC control is suited for all types of machining applications up to 4+1. An optional Fanuc 31iM-B control handles more demanding high speed machining applications as well as 5 axis simultaneous contouring.

Specifications

| Item / Model |

AHC-1600

Request a Quote |

|---|---|

|

X Travel |

63″ |

|

Y Travel |

50″ |

|

Z Travel |

40″ |

|

Spindle Center to Tabletop |

5.5″ – 55.5″ |

|

Spindle Nose to Table Center |

7.9″ Min. / 47.9″ Max. |

|

Table Size |

63″ x 32″ (72″/79″/118″ Length opt.) |

|

Max. Workpiece Load |

10,120 lbs. |

|

4th (B) Axis Rotary Table Diameter |

31.5″ |

|

4th (B) Axis Max. Workpiece Load |

4,400 lbs. |

|

Spindle |

35 HP (40 HP opt.) |

|

No. of Tools |

40 (60/80/120 opt.) |

|

Spindle Drive |

2 Speed Gearbox |

|

RPM |

6,000 RPM |

|

ATC Capacity |

40 (60, 80, 120 opt.) |

|

Weight – base only |

44,000 lbs. |