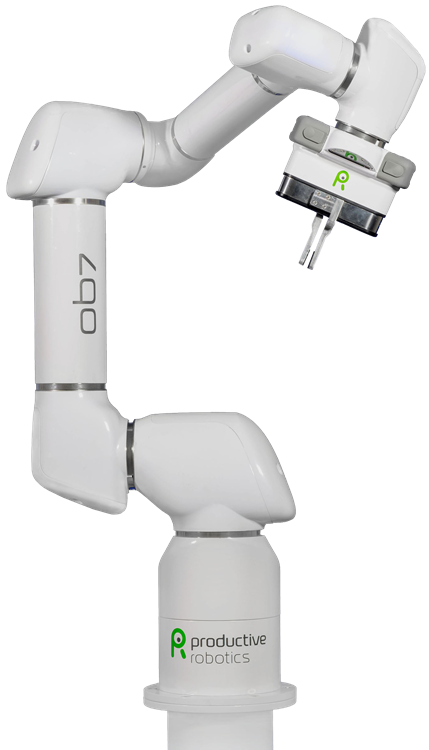

OB7 Family of Cobots from Productive Robotics

Absolute Machine Tools is proud to distribute and service OB7 Cobots from Productive Robotics, which formed in 2010 and focuses exclusively on designing and manufacturing Collaborative Robotic Systems. These smart true independent 7-axis collaborative robots use a “no programming” simple teaching platform. Simply show OB7 how to do the job and OB7 quickly learns.

The moment OB7 is delivered to your door, you have all the equipment needed to connect to your CNC machine. OB7’s simple setup and minimal integration requirements make it the most cost-effective solution for machine shops.

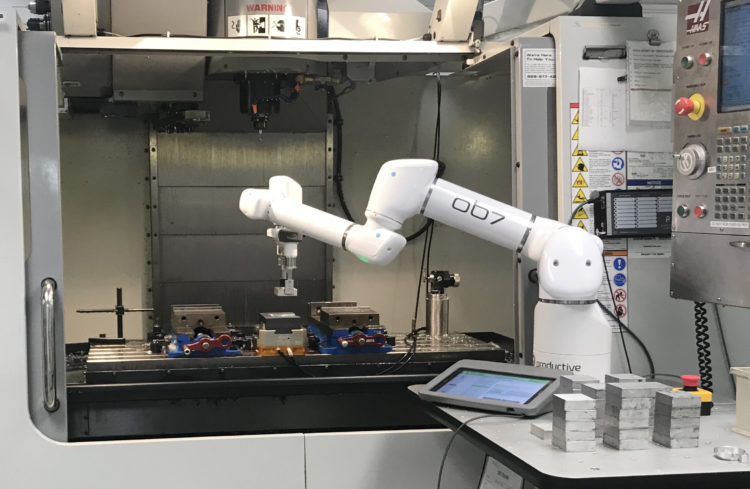

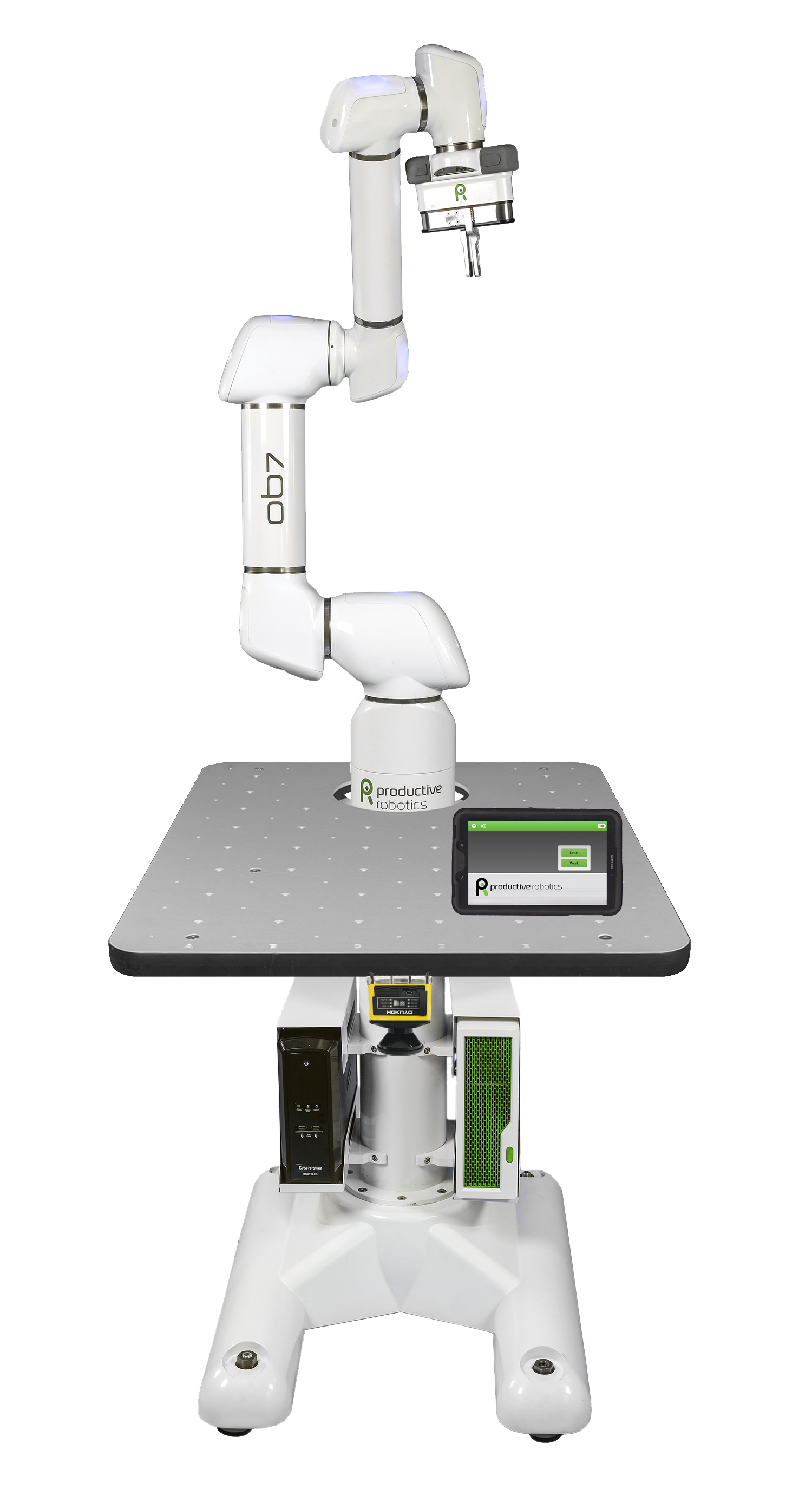

The 7th axis gives OB7 ultimate flexibility and dexterity to reach around objects or obstacles. This eliminates having to position the OB7 in front of the machine’s door and blocking both the work area and the operator. Each of OB7’s joints can rotate 360° in both directions allowing the cobots to work in more confined work spaces and areas.

OB7 Cobots integrate quickly and seamlessly into your existing operations, easily adding new automation possibilities to your existing production lines or machines. These collaborative robots are simple to set up with minimal learning time. They can handle small or large batch jobs and work safely without guarding. OB7 Cobots also reduce Bureau of Workers’ Compensation injury claims by helping to eliminate “continuous repetitive motions” that often affect employees.

Learn more about the benefits of OB7 Cobots and allow us to show you a real ROI by contacting Absolute Machine Tools at sales@absolutemachine.com!

Specifications

| Item / Model |

OB7

Request a Quote |

OB7-Stretch

Request a Quote |

OB7-Max8

Request a Quote |

OB7-Max12

Request a Quote |

|---|---|---|---|---|

|

Payload |

11 lbs. / 5 Kg |

8.8 lbs. / 4 Kg |

17 lbs. / 8 Kg |

26 lbs. / 12 Kg |

|

Reach |

1,000 mm (39″) |

1,250 mm (49″) |

1,700 mm (66″) |

1,300 mm (51″) |

|

Weight |

58 lbs. / 22 Kg |

58 lbs. / 22 Kg |

128 lbs. / 58 Kg |

127 lbs. / 58 Kg |

|

Flexibility |

7 Axes (Joints) |

7 Axes (Joints) |

7 Axes (Joints) |

7 Axes (Joints) |

|

Speed |

0 – 2+ m/sec. |

0 – 2+ m/sec. |

0 – 2+ m/sec. |

0 – 2+ m/sec. |

|

Joint Ranges |

± 360° (all) |

± 360° (all) |

± 360° (all) |

± 360° (all) |

|

Repeatability |

± 0.1mm, .004″ |

± 0.1mm, .004″ |

± 0.1mm, .004″ |

± 0.1mm, .004″ |

|

Safety |

ISO 10218-1 Compliant |

ISO 10218-1 Compliant |

ISO 10218-1 Compliant |

ISO 10218-1 Compliant |

FAQs

How is OB7 different from other collaborative robots?

OB7’s patent pending “teach without programming” means the user does not have to code or program. Simply show OB7 the job and it learns how to do it within minutes — both simple and complex jobs. It then saves and recalls stored automation jobs for use in the future. OB7 also has 7 joints, like a human arm. It has more freedom of movement (called degrees of freedom) so it is more maneuverable than most collaborative robots. It can reach around objects and obstacles in work areas that are not possible for cobots with fewer axes.

How is “teaching OB7” different from “easy programming”?

There is NO user programming with OB7. Common steps in a job — such as opening a door or pushing a button — are built in to OB7. Simply show it what to do. It learns in minutes and remembers the automated jobs for future use. It is the same for simple and complex jobs.

How do I make OB7 do what I want it to do?

Simply show OB7 how to do the job by moving it through the necessary steps. Specifics like the number of parts to put in a box, or how high to stack them can be entered on the tablet.

Does OB7’s “no programming” make it less capable than robots with programming?

Absolutely not! “No programming” just means that you teach OB7 what to do by moving it through the steps. It can learn as many steps as it needs to, and they can be as complicated as the job requires. Operations that don’t involvea movement (such as pausing or signaling an external device) are taught by touching an icon on the tablet.

How long does it take to “teach” OB7 a simple task?

About a minute. It’s easy AND fast!

How much training is needed to operate Ob7?

Very little training is needed. Basic teaching and operation of the robot is simple and quick to learn. A comprehensive manual and free telephone technical support are always available.

What are the benefits of a 7 axis joint?

OB7 has 7 joints, like a human arm, so it is more maneuverable than traditional collaborative robots. This means it can reach around objects and obstacles in work areas, which is not possible with fewer axes. It flexibly performs tasks such as loading or unloading parts around a machine door, or in tight work areas. Each of OB7’s 7 joints can rotate 360 degrees in both directions for unmatched maneuverability. One example is when tending a machine such as a CNC machine. 7 joints allow the robot to be placed to the side of the loading door instead of directly in front of it. This allows a person better access to the machine without having the robot in the way.

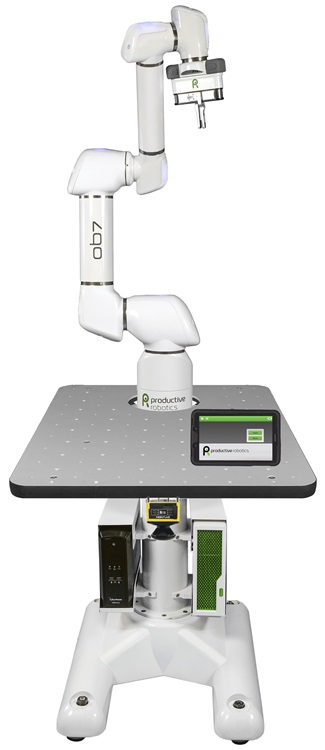

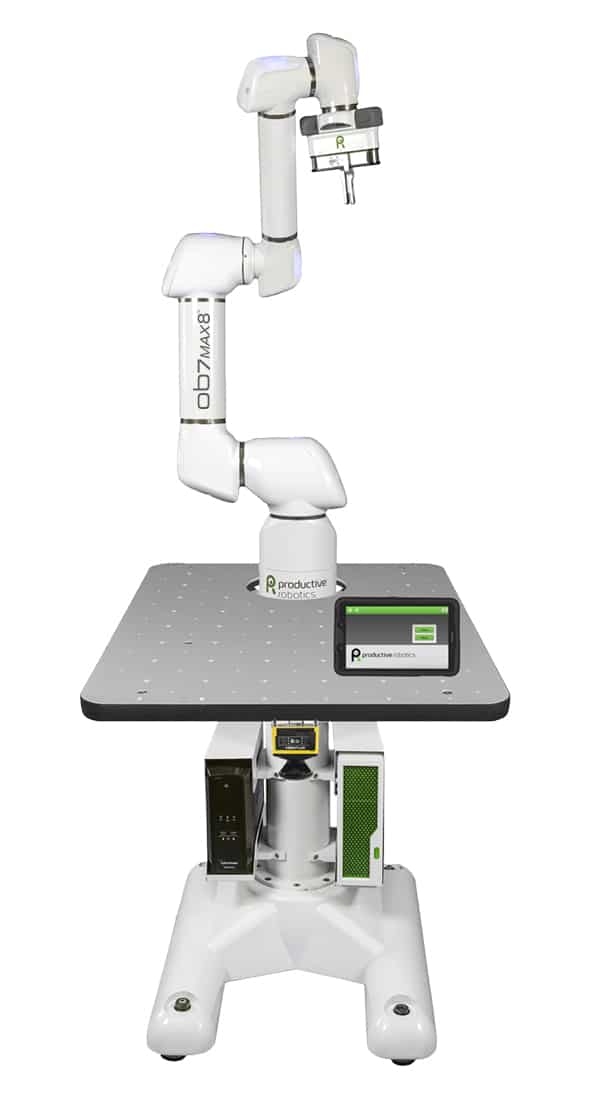

How do I install OB7?

In general, OB7 does not require “installation”. It arrives fully assembled, though the OB7 stand requires minimal assembly (approximately 20 minutes). Once that is done, simply roll OB7 up to the work area, lower its feet, and teach it the job.

What is the difference between an industrial robot and a collaborative robot?

Industrial robots are generally used in high volume manufacturing environments, requiring extensive setup and programming (sometimes taking months to complete). They lack force sensing capabilities required to allow them to operate safely among people. That is why they are locked in cages to keep people away from them. Industrial robot installations always require complicated programming and integration capabilities. Collaborative robots are more easily programmed so they are more flexible. They are designed to work safely with humans. They have force sensing capabilities necessary to have the robot stop when it bumps into something (e.g. a person). OB7 takes Collaborative Robotics to new heights by eliminating all forms of traditional programming.

How much weight can OB7 lift?

OB7 can lift 5kg, or about 11 lbs.

How can OB7 automate your existing production?

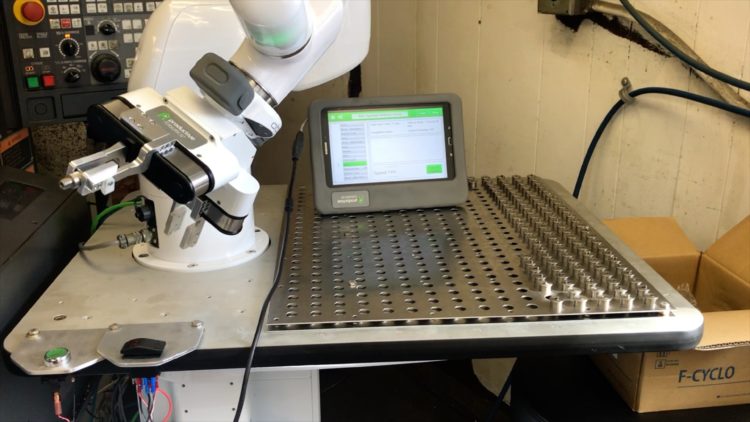

OB7 is capable of tending machines and processes that were previously manually handled. For instance, OB7 can be trained to load and unload parts from machines, pack items in boxes, or assemble products. By adding OB7 to a machine, it will maximize uptime and utilization and allow for running “lights out.” It can run 24 hours/7 days a week. Data and information are also available in real time.

Are there programming “templates”?

Some robots and computer programs use “templates” to simplify complex programming. Templates aren’t necessary for OB7 since it doesn’t require conventional programming.

What power is required for the OB7 cobot and controller?

All OB7 Products only require a 110-volt outlet. Plug into any standard machine and begin teaching it the job you want it to do!

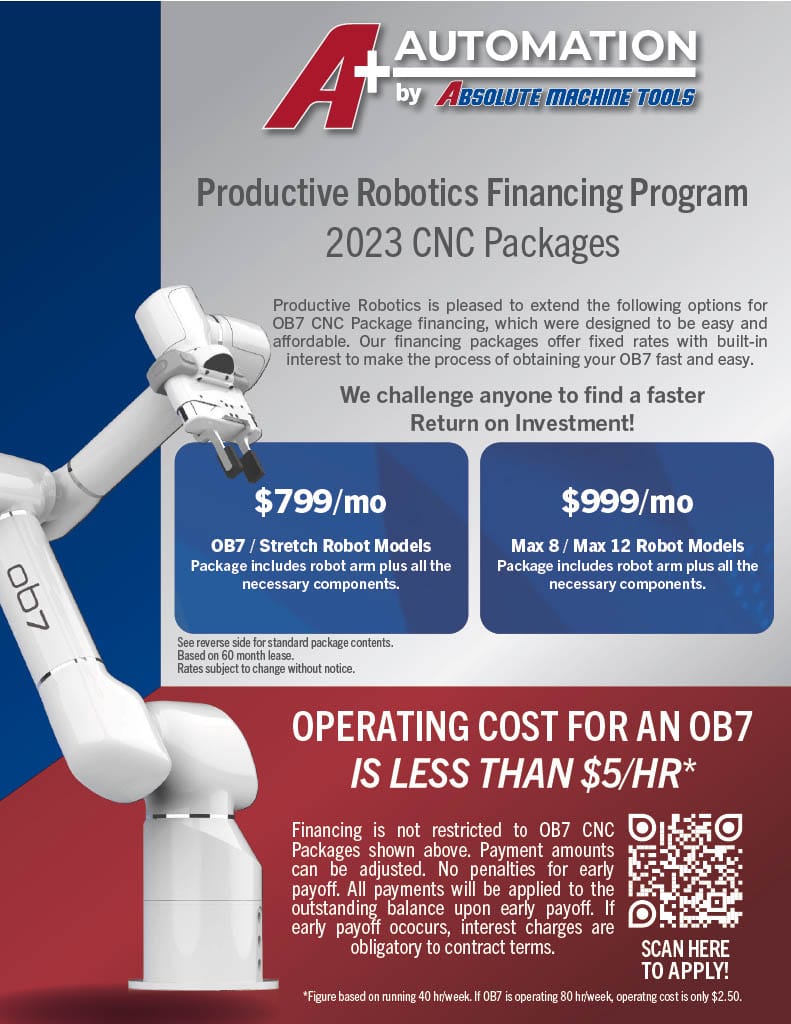

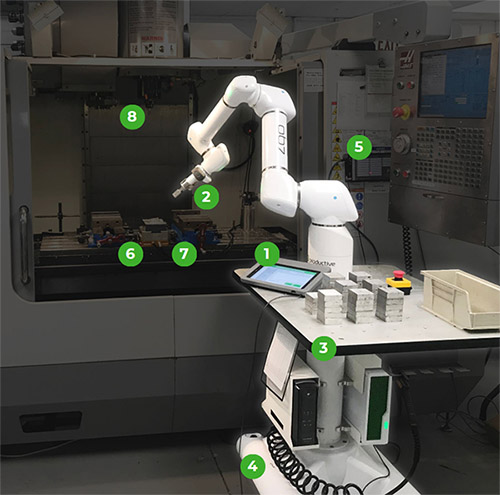

What is an OB7 CNC Package?

Absolute & Productive Robotics have specifically designed a CNC package for machine tool end-users.

A Fully Equipped CNC Package

Includes all the necessary components and accessories to begin automating instantly.

OB7 comes all-inclusive with the necessary accessories and equipment you need to connect to any type of CNC machine and begin automating on day one. The OB7 CNC Package makes it simple to work with all brands of CNC Machining Centers, Turning Centers, and other machines. As soon as OB7 arrives to your door, you can set it up and begin automating day one.

OB7 Cobot CNC Packages include:

Benefits of OB7-CNC Integration

OB7 Cobot News: