TJR

TJR (Tan Jia Precision Technology) Rotary Tables

TJR, or Tan Jia Precision Technology, is a well-established supplier of rotary tables to machine tool OEMs such as Doosan, DMG Mori, Mazak, Hardinge, YCM, Feeler, Leadwell, Bulova and Tongtai.

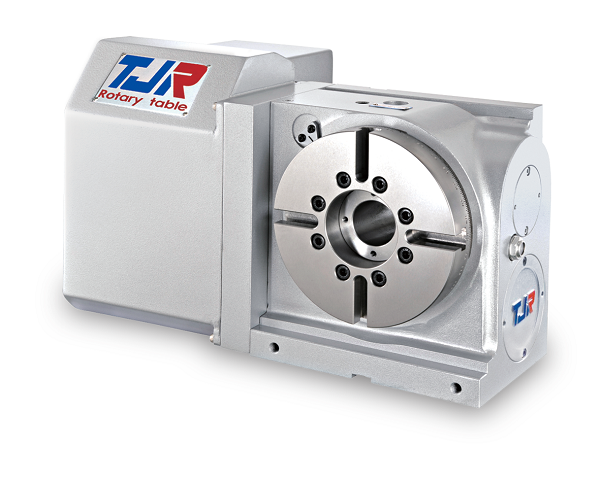

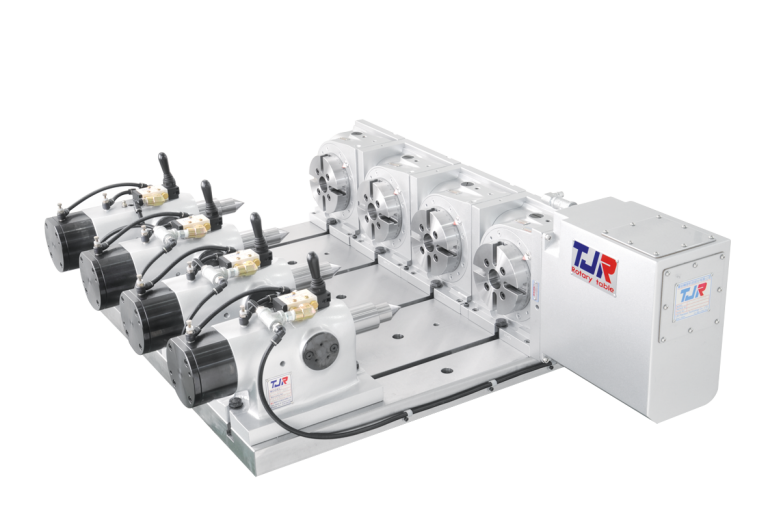

TJR supplies the most technically advanced rotary tables in the industry, with special emphasis on direct drive and 5c collet 4th axis series units.

The company originated as a rotary table sales and service agent prior to establishing TJR as an OEM in 2009. After much success, the company grew to having the largest market share of machine tool accessories in China. Today TJR is a top OEM with offices all around the world. Their rotary tables are built with high quality features such as an anti-wearing worm gear and shaft made of high tensile brass for durability. Further, encircling braking systems use a large clamping range to prevent displacement during heavy-duty cutting. For tilt rotary tables, TJR offers a 2+1 independent braking system and large diameter radial and axial preloaded bearings for rigid support during 4th and 5th axis cutting on both single and dual arm rotary tables. A 3-year parts warranty is standard for all new TJR rotary tables.

To learn more about TJR, see our rotary tables section in our site or visit www.tjr.com.tw.

TJR CNC Rotary & Index Table Core Technology

TJR takes pride in producing high-quality parts for their rotary tables and indexers. Here are three main parts of a rotary table that demand high accuracy and high quality:

1. Dual-lead Worm and Worm Gear

TJR rotary tables feature a dual-lead worm and worm gear made in Japan made from high tensile brass with abrasion resistance of 25.1 mg/cm2 per 10,000m. It has estimated wear life of 10 years, more than twice the wear life of components made from aluminum bronze.

2. High Performance Braking Mechanism

The high performance braking and clamping mechanism is designed with full 360∘circumference hydraulic clamping that is synchronized for the entire table. Having the clamping area on the entire circumference of the table allows for improved rigidity, making it an ideal feature for heavy cutting application. With a higher clamping force than conventional disk braking systems, the mechanism’s proximity to the worktable reduces deviation during cutting.

3. Radial-axial preloading bearing

TJR uses Radial-axial preloading bearings. The axial component of these bearings has an axial cylindrical roller and cage assembly, an outer ring, L-section ring and shaft locating washer and is axially preloaded after fitting. The radial component is a full complement preloaded cylindrical roller set. The outer ring, L-section ring and shaft locating washer have fixing holes. The unit is located by means of retaining screws for transport and safe handling. The Radial-axial preloading bearings offer static rigidity and high durability for heavy cutting both horizontally and vertically.