Guide bushings are what separates a CNC Swiss lathe from a conventional lathe. First called an anti-friction guide bushing, the rotary guide bushing was patented in 1963 to hold bar stock of different diameters to be machined in an automatic screw machine. The guide bushing rotates the bar stock and pushes the workpiece into and out of the cutting tool.

This was particularly adaptable for use in a Swiss-type automatic screw machine. Such machines are generally provided with a headstock movable axially to the machine frame while rotating the bar stock, and the adjustable bushing makes it possible to support turning bar stock rigidly, and at all times close to the turning tools. This provides for the making of parts at high quality finishes and extreme accuracies.

Rotary or Fixed: Which Type of Guide Bushing Is Preferred?

A rotary guide bushing rotates simultaneously with the workpiece and is best used when turning wider parts, with tolerances greater than +/-0.0005”. Fixed guide bushings remain stationary while the bar stock spins and are best used for parts where tighter tolerances are required.

There are uses for both types of guide bushings; however, most are for use with a rotary guide bushing. The rotary guide bushing acts as a slave to the material as it’s spinning and runs with the main spindle. This prevents the material from slipping in the guide bushing as long as the rotary guide bushing is set properly.

A fixed guide bushing remains static as the bar in it spins. This is not typically popular because there is a tendency for the fixed guide bushing to damage the material it is holding. For instance, if you are making a part that you are turning the OD, you don’t want your fixed guide bushing to leave marks on the outside of your material. For excellent surface finish, you always want your material to spin with the guide bushing, so it stays in contact with the part, minimizing the amount of marring or scratching.

Are There Any Reasons Not to Use a Guide Bushing on a Swiss Lathe?

Since the guide bushing is one of the best attributes of a Swiss lathe due to the rigidity is offers, there really isn’t a reason why a shop would buy a Swiss lathe without a guide bushing. So, if a shop doesn’t see the need for the guide bushing, then they are better off buying a conventional lathe for less money.

However, there are applications out there where you can remove the guide bushing and just use the headstock itself, but then you are going to have the same issues you have on a conventional lathe as previously mentioned. Applications for removing the guide bushing may be for profiling stock that would not be efficiently turned using a guide bushing. Just because the machine can do it, doesn’t mean you should, but if the Swiss lathe is the only lathe in the shop, then a removable guide bushing may be useful, especially if you have to run a part at that particular moment and don’t have any other options.

Has Every Swiss Shop Eventually Evolved Towards Purchasing Machines with Guide Bushings?

Yes. Even though there are machines out there that are marketed as being able to remove the guide bushing as a selling point, almost all Swiss OEMs today sell their Swiss lathes with guide bushings in them. In the end, removing the guide bushing defeats the purpose of buying a Swiss lathe.

A Swiss lathe is used when there is length to diameter ratio of parts being made. Length-to-diameter ratio (L/D) is the ratio of the length of the part to its outer diameter. So, a long thin part being machined is best turned being held by a guide bushing on a Swiss lathe as opposed to a conventional lathe holding the workpiece in a chuck and allowing the cutting tool to move further and further away.

Frequently Asked Questions About Swiss Lathes

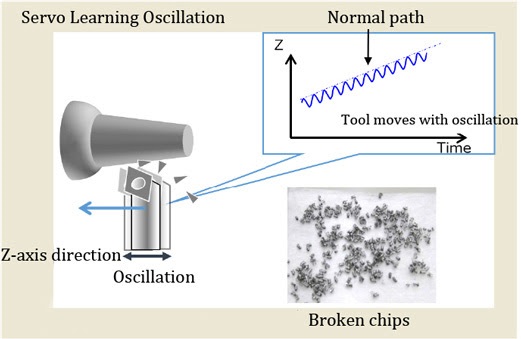

What is “Breaking the Chip” on a CNC Swiss Lathe?

During the machining process, chips tend to pile up around the part or tool, destroying the cutting tool or scratching the outside finish of the part. Servo Learning Oscillation is a feature on Nexturn Swiss lathes that eliminates these long stringy chips from collecting. Applying this feature during the cutting process is how the phrase “Breaking the Chip” was born. Continually changing frequencies through the X, Y, and Z axes, along with interrupting cutting on the part, allows the chips to break away cleanly for flawless cutting. This feature is best used on materials such as aluminum or stainless steel.

Can Swiss lathes be automated?

Yes! Swiss lathe automation can be achieved through the use of a bar feeder. Automatically feeding 12’ long bar into a Swiss lathe will dramatically increase your shop’s efficiency and throughput. Planning for families of parts in which the same bar size can be used for multiple applications will also decrease time wasted changing to different bar sizes between applications.

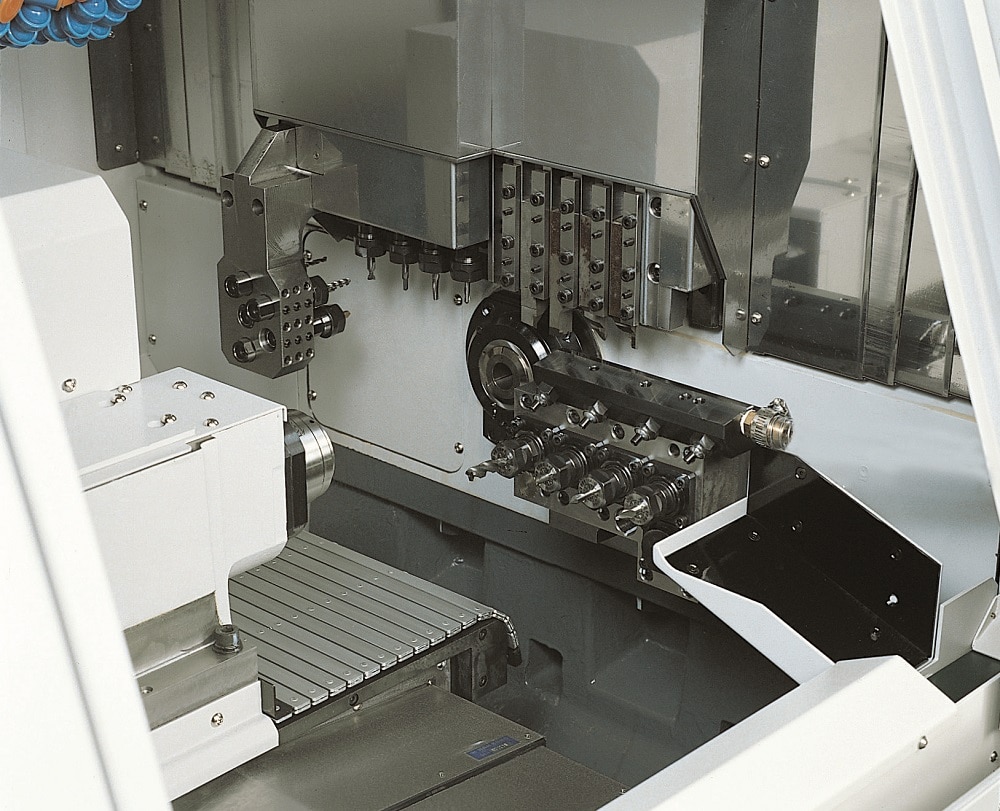

Why is the Swiss machine tooling capacity significant?

CNC Swiss machines can accommodate 20 or more tools in the tool zone, many with live tooling. Combined with a sub-spindle and backworking stations, this means the need for secondary operations on complex parts is virtually eliminated, often allowing for production of finished, ready-to-ship parts.

Learn More About Swiss Lathes Today

Absolute Machine Tools has been the U.S. distributor for Swiss lathe manufacturer Nexturn for years. We provide factory-trained service personnel and technical support to ensure superior long-term support. We also stock a full range of tooling and accessories for Swiss Turning applications and offer training solutions to get your team up to speed quickly and efficiently.

Email us today at info@absolutemachine.com or call (800) 852-7825 to discuss how Swiss Turning could benefit your business.