Barrel Rifling Processes Explained: Broach, Cut and Button

Every weapon that has a barrel needs to be rifled in some way. The precision of a barrel’s rifling is pivotal in defining its accuracy and performance. With methods as varied as the firearms they create, understanding the nuances of button, cut, and broach rifling can set your operations apart. Absolute Machine Tools is proud to import and distribute all three of Precihole Machine Tools’ innovative barrel rifling machine lines to North American manufacturers.

The Art of Barrel Rifling: Button, Cut, and Broach

Rifling is the art of carving spiral grooves inside the barrel, a critical step that when done well ensures accuracy and precision.

Button Rifling: The Efficient Innovator

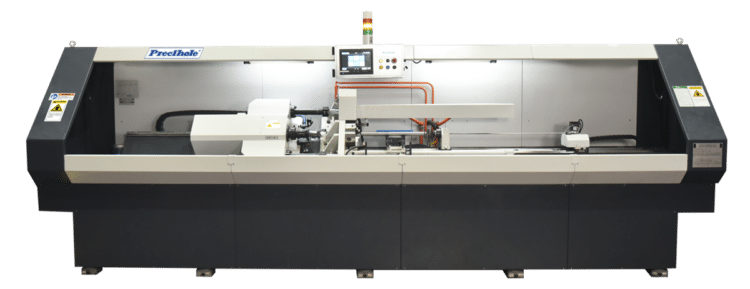

Button rifling stands out for its efficiency and precision, especially suited for small caliber firearms where cost and production speed are critical. The process involves a rifling button that’s precisely pushed, pulled, and rotated through the barrel, displacing metal to form the rifling grooves. This technique not only ensures a high degree of accuracy but also stabilizes the projectile by imparting a spin during its flight. Key to this method are the state-of-the-art machines equipped with anti-backlash helical guides and rotary encoders that ensure the perfect interpolation of linear and rotary motions, making it ideal for mass production of sporting and recreational firearms.

Cut Rifling: The Precision Maestro

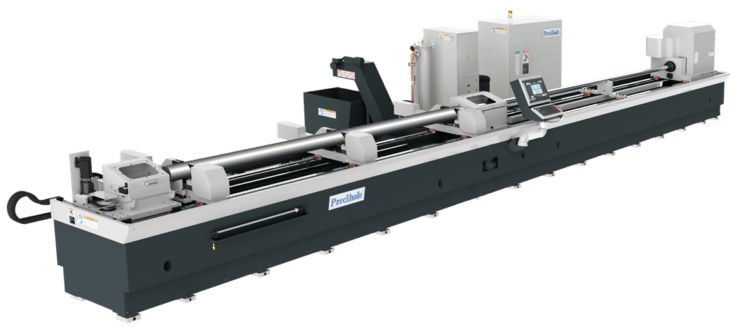

Cut rifling is synonymous with custom precision and tight tolerances, preferred for high-quality barrels where each groove is cut with unmatched accuracy. This labor-intensive process starts with securing the barrel in a vice, followed by the precise cutting of grooves using servo-controlled mechanisms for indexing and pulling. Cut rifling excels in creating barrels for sniper rifles and competition firearms, where precision is non-negotiable. The meticulous nature of this method allows for unparalleled customization and repeatability, often finished with lapping or honing for a smooth bore.

Broach Rifling: The Powerhouse

Broach rifling, efficient for medium to large caliber barrels, employs a long broach tool with cutting teeth to carve the rifling grooves. This method shines in its ability to produce rifled barrels en masse, offering a cost-effective solution for high-volume production without sacrificing quality. The broach is designed to gradually increase in diameter, ensuring a tapered shape of the rifling grooves, controlled by servo-driven and ball screw or rack and pinion mechanisms. While it may not reach the precision level of cut rifling, its efficiency makes it indispensable for large-scale operations.

Making the Choice: Tailoring Barrel Rifling Technology to Need

Each barrel rifling technique serves a unique purpose, influenced by factors such as the intended use of the firearm, production efficiency, and cost considerations. Button and broach rifling are often favored for their efficiency in mass production, while cut rifling remains the choice for applications demanding the highest precision. Understanding these methods allows manufacturers to select the most appropriate technology based on their specific needs.

Achieve Deep Hole Drilling Excellence with Help from Absolute Machine Tools

Absolute Machine Tools, in partnership with Precihole Machine Tools, champions the advancement of deep hole drilling and barrel rifling technology in North America. With over four decades of innovation, Precihole has earned a global reputation for delivering solutions that meet the exacting demands of the firearms industry. Absolute Machine Tools’ commitment to excellence is evident in their support for Precihole’s state-of-the-art machine tools, ensuring customers have access to the best in precision engineering. Contact us today to explore our comprehensive range of products and experience the unparalleled support we provide to our valued customers.