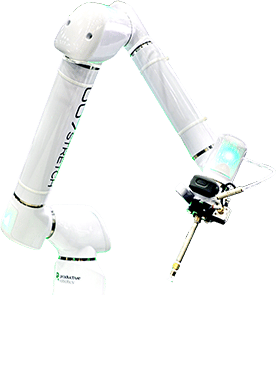

Gun Drilling & Finishing Machines

Gun Drilling or deep hole drilling is a hole making machining process that generates holes that can be up to 200 times longer than the diameter of the hole. Applications in today’s industry demand deep hole drilling in exotic materials or hard super-alloys while maintaining accuracy and productivity. Maintaining straightness of holes with good tolerances and surface finish requires the proper machine. Gun drilling machines from Precihole perfectly fit the mold of extraordinary quality machines with superb precision, tolerance, and surface finish. Browse our extensive range of Precihole Series to find one that exactly meets your needs.

Precihole — The Leader in Deep Hole Drilling and Hole Finishing Equipment and Solutions

As one of the most recognized machine tool distributors, Absolute Machine Tools remains committed to supplying customers with the highest quality tools and equipment from reputable manufacturers worldwide.

With the most complete range of deep hole drilling and finishing solutions, Precihole is easily the leading provider of such equipment, catering to the requirements of diverse segments and companies across the world. Their expertise in this niche technology has earned them the enviable position of the leading brand across the globe.

Precihole offers custom engineering solutions to meet the specific demands of over 150 varied types of applications in more than 20 sectors. Oil & gas, automotive, aerospace, defense and firearm, medical implants, die and mold, seamless tube manufacturing, energy, and hydraulic cylinders are some of the most crucial domains for which they design highly effective gun drilling machines.

In addition, they also cover other application areas including but not limited to BTA (STS) / ejector drilling, pull boring, counter boring, honing, pull reaming, roller burnishing, and bottle boring. Moreover, as an ISO 9000-certified company, it maintains strict compliance with quality standards. A focus on product optimization by increasing ease of use, accuracy, performance, workmanship, and aesthetics makes adherence to the highest quality benchmarks easy. Their consistent optimization efforts have resulted in a tremendous improvement in key performance metrics such as hole straightness, bore tolerance and surface finish.

Machines