The Challenge: Demand Outpacing Production

As a full-service machine shop, True Precision Machining promises quality control, quick turnaround time and innovative solutions to meet their customers’ challenges and requirements. However, even with their highly trained and skilled team, it was challenging to meet certain deadlines.

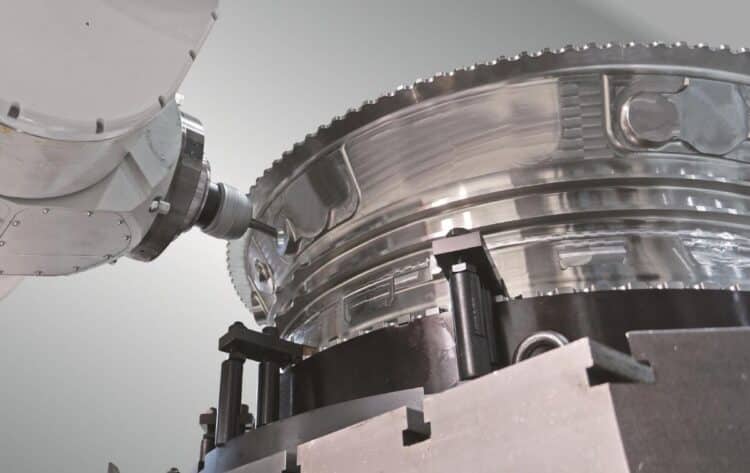

Producing parts fast enough on their wire EDM machine is just one example of this challenge.

“We typically run two shifts per day for five days, totaling 80 production hours per week,” explained Marvin Rodriguez, vice president of True Precision Machining. “A 500-part job would take at least a week to finish working at that pace—and that’s not accounting for downtime or breaks. To stay competitive and meet our customers’ high demands, we need to be faster than that.”

Rodriguez recognized that the existing production schedule took advantage of only 80 of the 168 hours in a week. What if True Precision could operate at a higher capacity, taking advantage of all available hours, unhindered by machine downtime?

The Solution: 24/7 Production with OB7

Discovering OB7

During their extensive research of collaborative robotics, True Precision discovered Productive Robotics’ OB7 at a tradeshow and taught it a task on the spot.

“We were impressed by the no-programming user interface and how simple it was to teach the cobot tasks. This would be a solution that we could develop on our own without hiring outside integration,” stated Rodriguez.

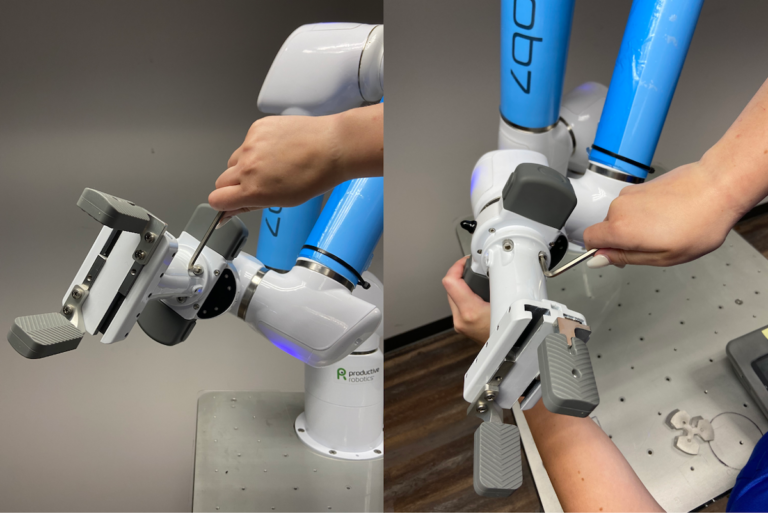

True Precision was also drawn to OB7’s seven axes, which provide greater flexibility and the ability to work in confined spaces.

“We saw how well OB7’s 7th axis worked during the CNC demo, and we wanted that in our shop,” emphasized Rodriguez.

The 7th axis is an especially desirable feature for machine shops because it allows operators to place OB7 to the side of a machine door, rather than directly in front of it. The OB7 can reach around into the machine, freeing up space for machine operators to work.

It was clear that OB7 is an easily teachable robot and one with the flexibility to fit the physical needs of True Precision’s shop—and what’s more, it would allow them to expand their hours of production through working “lights out” or around-the-clock even when employees are not at the facility.

Ready, Set, Assemble!

Now on the road to faster production, it was time to install the OB7 Alpha Wire EDM 5 axis machine. With their skilled staff, True Precision set up the automation work cell entirely on their own.

“We did not have any prior experience with cobots, but we were able to create the necessary tooling and configure our environment to work with OB7,” stated Todd Ackert, President of True Machining. After the few days spent planning the work cell, the team turned to assembling the OB7 and had it up and running in a matter of hours.

“OB7’s intuitive user interface made the process simple. We physically moved the robot control handle to introduce a task and customized our waypoints on the tablet interface for more precision,” stated Rodriguez.

The simple teaching platform is a key benefit to working with OB7 for many teams—it enables fast job teaching and requires absolutely no programming.

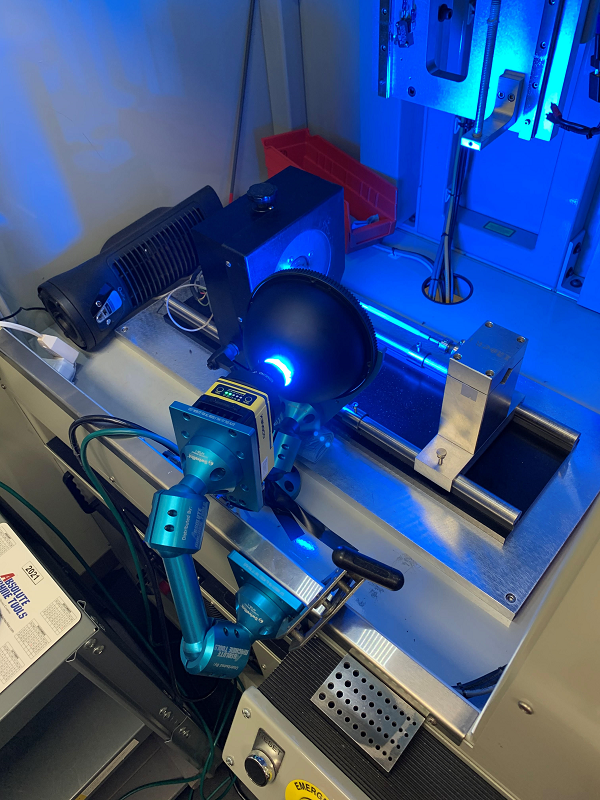

The 500-part job on the wire EDM machine was soon working 200% faster and could continue to operate round-the-clock.

“We finished a job in 3.5 days that would have taken a week to complete” said Rodriguez. “Working ‘lights out’ with OB7 allows us to go home and return the next morning with a job completed, ready to start the next. OB7 has saved us significant time and money, while increasing quality and precision.”

True Precision also recognized the valuable and reassuring role of Productive Robotics’ dedicated support team.

“If we had a question, we called Productive Robotics’ support team. They would help us over the phone or come out to our facility,” added Ackert.

The Future: Expanding Implementation of OB7 to Grow Business

True Precision attributes its success over the years to effectively introducing modern machinery and state-of-the-art equipment to deliver quality results. Implementing OB7 is a prime example.

“People think that robots take away jobs, but it has actually helped grow our business, become more competitive and better utilize the talents of our team,” stated Ackert.

OB7 allowed True Precision to bring in more work, meet deadlines faster, and simultaneously allow their workers to focus on other highly valuable tasks. The success of OB7 was so immediate, simple, and effective, that looking forward, True Precision plans to implement OB7 on multiple other machines in their facility.

“Working with OB7 has been a highly rewarding experience,” emphasized Ackert. “And in the process, we learned to strategize more efficient, creative, and innovative methods for automating future jobs with collaborative robots.”

“People think that robots take away jobs, but it has actually helped grow our business, become more competitive and better utilize the talents of our team.”

Boost Your Productivity with OB7

Absolute Machine Tools is a proud distributor of the OB7 Collaborative Robot in the United States. Please don’t hesitate to call us today at 800-852-7825 to learn how a Collaborative Robot can add new automation possibilities to your existing production lines or machines. We continue to provide A+ sales, service and support and are here to answer questions about your OB7 Cobot!