Horizontal

Machining Centers

CNC Horizontal Machining Centers (HMCs) – Powerful Multi-Side Precision for Demanding Production

Horizontal machining centers (HMCs) are built for speed, accuracy, and continuous operation in high-volume environments. With horizontal spindle orientation and integrated pallet changers, HMCs allow for multi-sided machining in fewer setups, superior chip evacuation, and significantly reduced idle time. These machines are the go-to choice for manufacturers who need rugged construction, thermal stability, and lights-out performance.

Many of today’s HMCs can be seamlessly integrated with dual-pallet changers, linear pallet systems, pallet pools, and robotic automation — enabling flexible, unattended, and high-mix production. Whether you’re cutting lightweight aluminum or heavy-duty steel, horizontal machining centers deliver the throughput, repeatability, and automation readiness that modern manufacturers demand.

Benefits for Metal Cutting Manufacturers

Machines

Solutions from Absolute Machine Tools

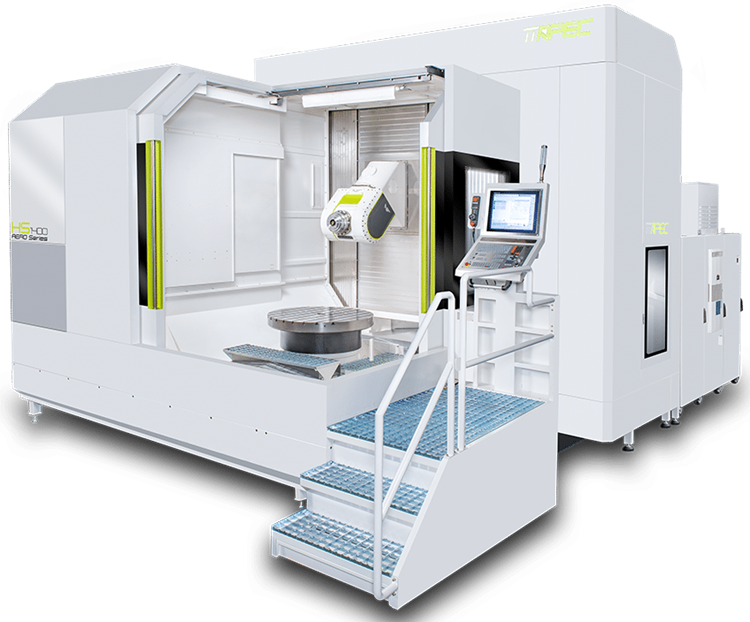

APEC Horizontal Machining Centers

APEC (Asia Pacific Elite Corporation), a Tong Tai TTGroup subsidiary, builds high-speed 5-axis horizontal machining centers for aerospace, automotive, and mold & die industries.

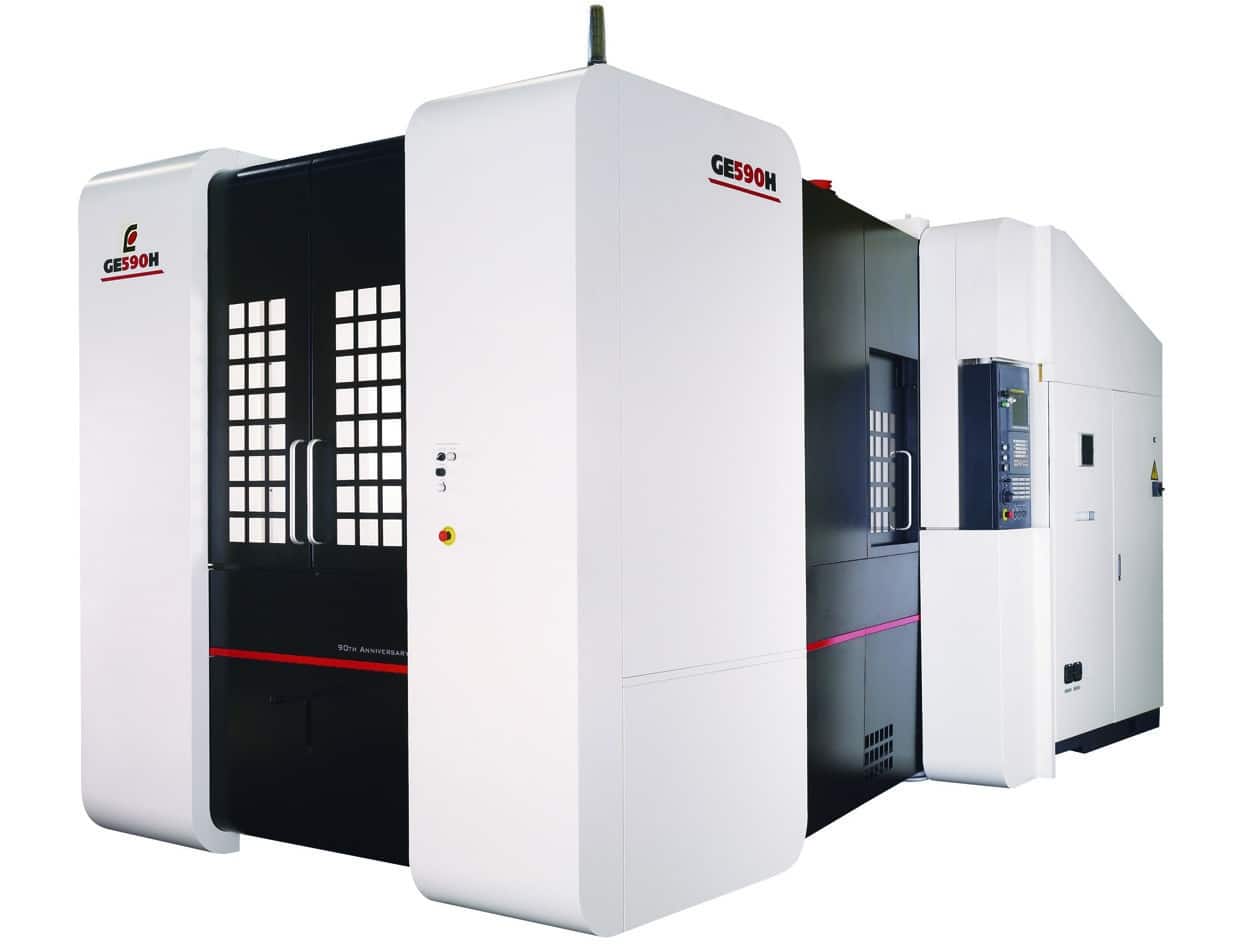

Enshu Horizontal Machining Centers

Enshu’s GE Series is known for Japanese precision, uptime, and unmatched thermal control.

Johnford Horizontal Machining Centers

Johnford, a trusted Taiwanese brand since 1979, delivers large-capacity, high-rigidity solutions for shops that require customized configurations.

Let’s Build Your Next Horizontal Machining Solution

Ready to take your production to the next level? Whether you need high-speed 5-axis machining, heavy-duty cutting capability, or fully automated palletized workflows, Absolute Machine Tools has the right solution. Contact us today to speak with our engineering team and discover how we can deliver a turnkey horizontal machining system tailored to your performance, part, and process goals.