Tongtai

Machinery

Tongtai Horizontals & High Automation

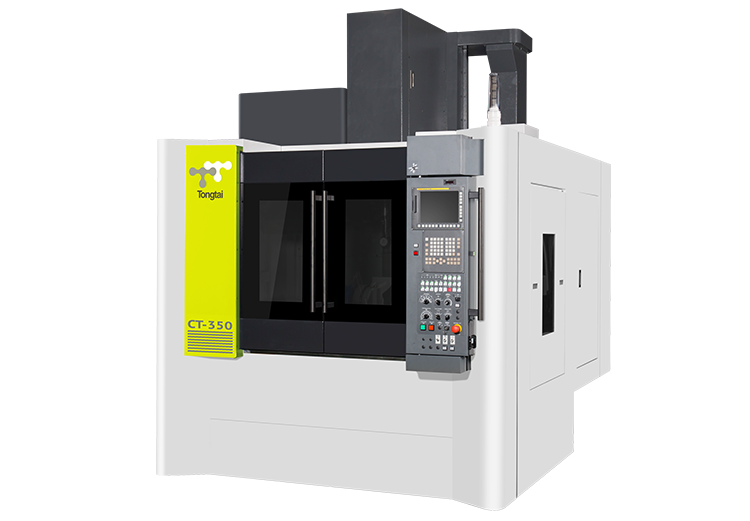

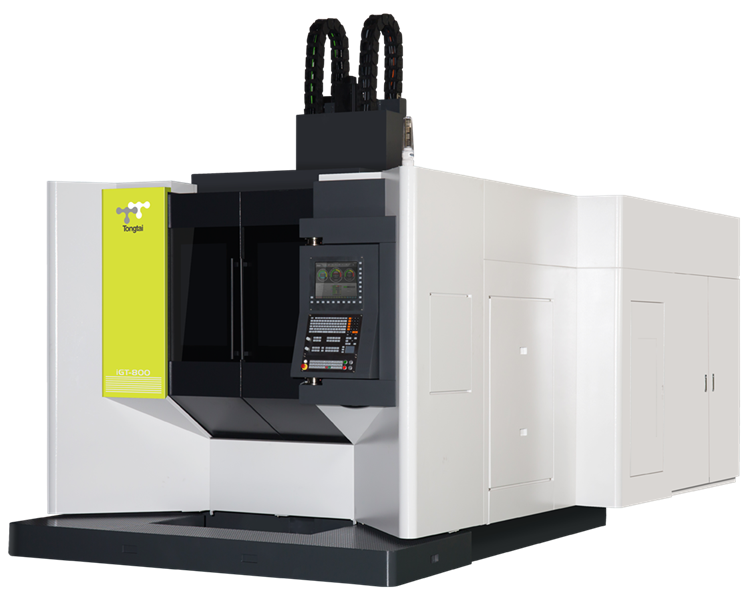

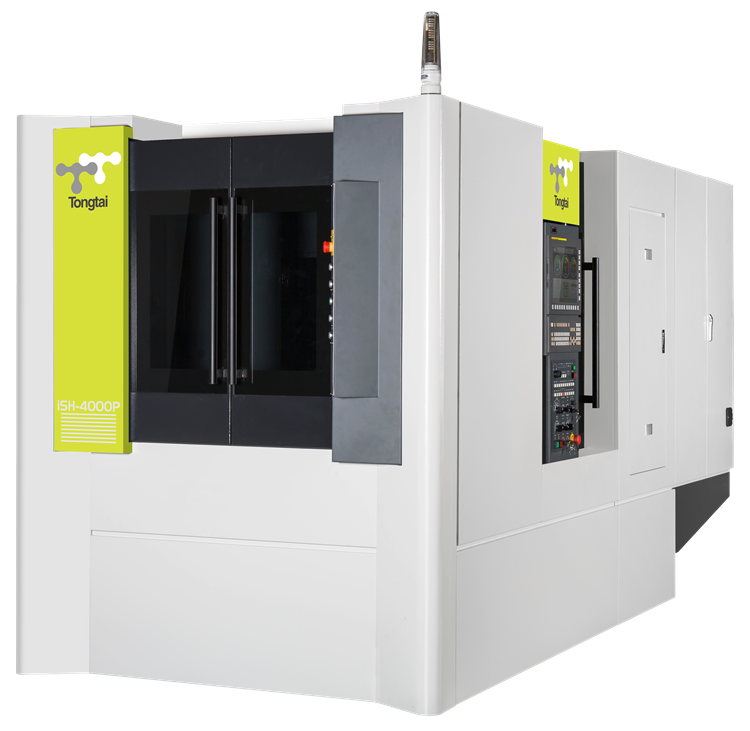

As the Taiwanese OEM for Hitachi Seiki for many decades, Tongtai knows how to build state-of-the-art horizontal machining centers, multitasking lathes, 5-axis machining centers, and multi-axis mill/turn centers.

Tongtai will exceed the demands of any manufacturer with high volume, high precision machining needs, as their machines feature heavy cast iron construction combined with blazing speed. They are proven to deliver more parts per hour than competitive machines costing thousands more. Tongtai offers Japanese quality and performance for only a fraction of the cost!

Tongtai Products Include

Machines

Tongtai Partners with Fanuc to Create a Production Management Tool for Real-Time Monitoring

TIMS, an acronym for Tongtai Integrated Monitoring Systems, is a new software initiative created between engineers and technology experts from both Tongtai Machine Tools and FANUC. TIMS is software geared more towards process and machine tool management, rather than production monitoring. The software enables management to monitor real time and historical parameters on each machine within a cell, and the production line as a whole, from anywhere on the intranet or internet. The data collected is downloadable from the software and can be extrapolated into Excel for analyzing, sharing, and emailing purposes.

There are 4 main functions in TIMS: Machine Situations Monitoring, Production Line Management, Operation History Recording and Alarm History Recording. Machine Situations Monitoring is used by team members to check the real time machine conditions pertaining to spindle speed, loads on axes, and the current program number in operation. Production Line Management assists production managers in monitoring cycle times on all machines within a cell, monitors operations for comparison of cycle times and statuses of jobs. Management can fully inform themselves as to if the job is currently on time and running to full capacity, or needs improvements to meet deadlines and quality control specifications. Operation History Recording allows for comparing variances of functionality with the machine that can potentially affect capacity and volume. This function helps both management and maintenance understand where problems are arising that are affecting the machine’s performance. And finally, Alarm History Recording tracks the CNC control alarms which will assist in resolving potential issues before they become a serious problem.

These 4 functions together create the perfect production line information base for proper factory management in real-time. Another benefit is that it can be used by sales to secure additional production jobs by offering data and security to customers ensuring their job will be properly supervised and controlled for exceptional quality and timeliness. TIMS is now being utilized by many large manufacturing facilities here in the United States. It’s a smart tool, for smart business, for today’s competitive environment and it is solely offered by Tongtai brand machines from Absolute Machine Tools.