Seiki

Powered by Ugint

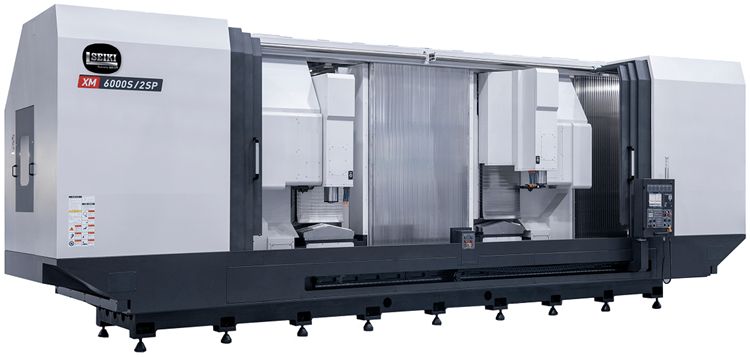

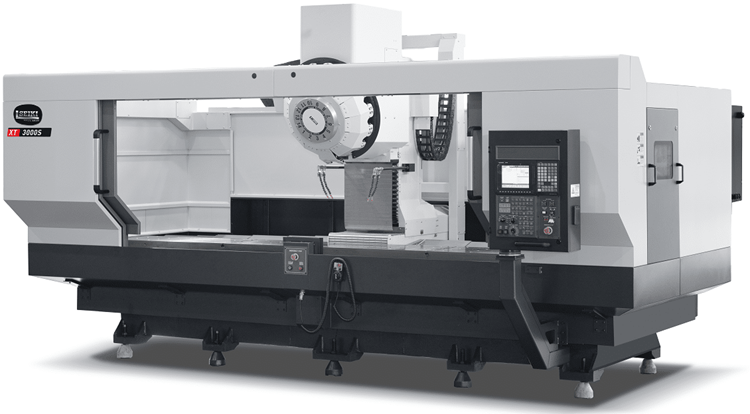

Seiki High Production Mill/Drill/Tap Centers

Seiki has specialized in manufacturing high speed, high precision CNC drilling and tapping centers since 1991. Since then, the company has strived for continuous technology development and quality improvement and has succeeded in establishing rapport with customers worldwide.

Seiki has grown with innovative management, creative developers, and efficient manufacturers, and has been pursuing the concept of quality first. Seiki’s product line include high-speed, high-production vertical tapping centers, cost-effective machining centers, special purpose machine tools, and more.

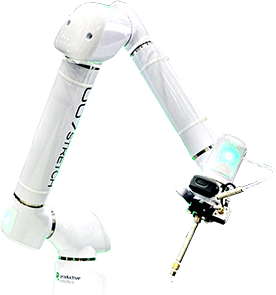

Embracing Automation

Our A+ Automation team offers simple and affordable solutions for CNC machine automation