Accutex GA Series – Moving Table, Submerged-Type, Small Footprint Linear Motor Wire EDM

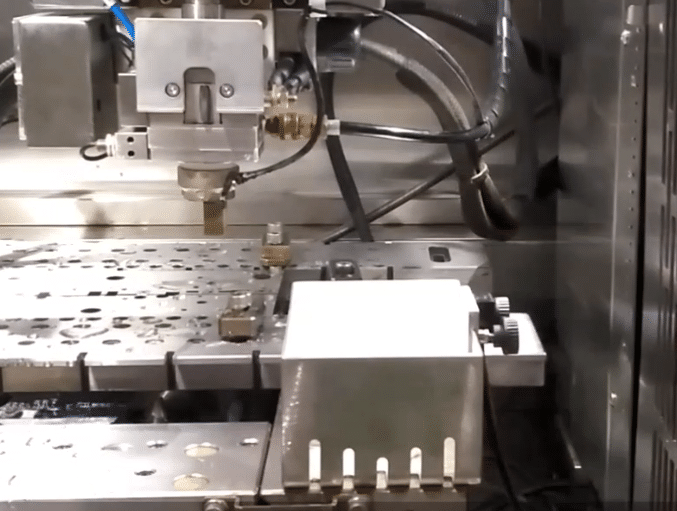

The Accutex GA Series Wire EDM machines are designed as moving-table, submerged-type EDMs that deliver high accuracy and cutting speed within a compact footprint. Available in both ball-screw and linear motor models, the GA Series offers manufacturers a flexible, economically priced solution for precision machining. Its rigid gantry construction, sub-micron feedback system, and Windows-based UeX10 CNC control ensure exceptional stability and accuracy. Engineered for aerospace, medical, automotive, and mold & die industries, these machines combine speed, precision, and cost-effectiveness to meet the demands of today’s high-performance manufacturing environments.

The GA Series wire edm machines compete directly with Mitsubishi, Makino, GF AgieCharmilles, Sodick, and Fanuc, offering world-class performance, accuracy, and reliability at an exceptional value.

Key Features

- Accutex Linear Shaft Motor System: In-house linear motor delivers maintenance-free, backlash-free motion and 10% faster servo response than ball-screw drives.

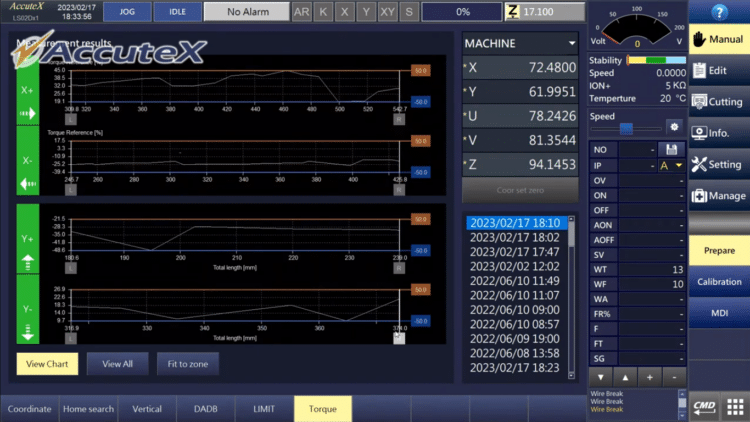

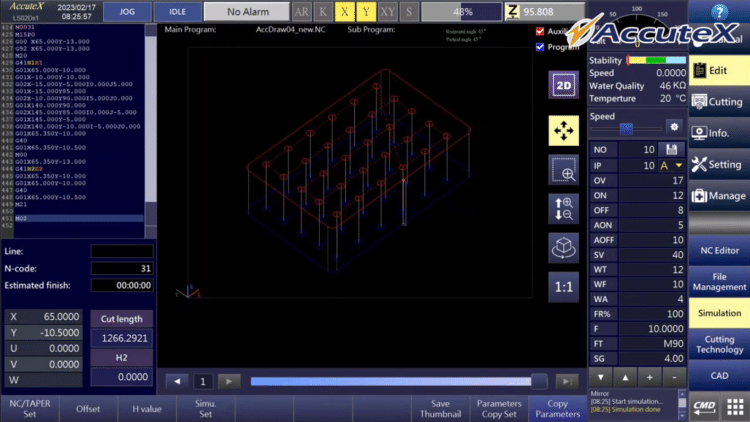

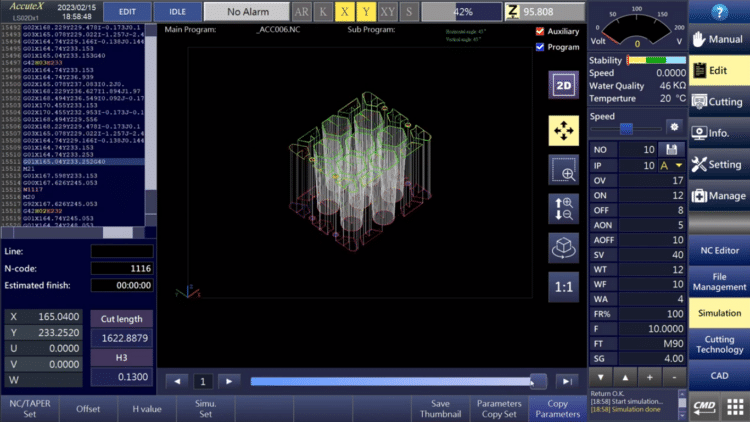

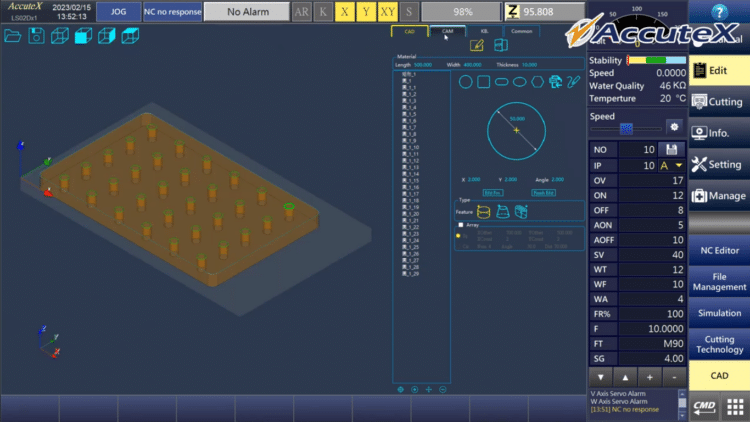

- UeX10 64-bit Windows CNC Control: Intuitive touchscreen interface with real-time 3D graphics, adaptive discharge control, and AI learning.

- High-Rigidity Gantry Structure: Symmetrical, FEA-validated casting ensures superior stiffness and geometric accuracy.

- Fagor Glass Scales (0.000004”): Closed-loop feedback on all axes guarantees sub-micron positioning and repeatability.

- Automatic Wire Threading (AWT): Patented annealing and break-point re-threading for reliable submerged operation.

- SD Master Stable Discharge Circuit: Proprietary technology for consistent spark energy, improved surface finish, and reduced electrode wear.

- Advanced Dielectric Management: Temperature-controlled chiller and multi-stage filtration maintain stable cutting conditions.

- Full Submerged Machining: Reduces wire vibration, enhances straightness, and improves surface quality.

- Ergonomic 21.5” Touchscreen Interface: Modern user layout with guided menus and diagnostic support for efficient operation.

Specifications

| Item / Model |

GA-43AL

Request a Quote

|

|---|---|

|

X Axis Travel |

15.75″ |

|

Y Axis Travel |

11.81″ |

|

Z Axis Travel |

8.66″ |

|

U Axis Travel |

2.36″ |

|

V Axis Travel |

2.36″ |

|

Table Feed Rates |

40.0 IPM |

|

Max. Taper Angle |

±45° |

|

Max. Workpiece (XYZ) |

29.52″ x 24.80″ x 8.46″ |

|

Max. Workpiece Weight |

1,067 lbs. |

|

Wire Diameter |

0.006″ – 0.013″ |

|

Wire Spool Feed Rate |

60 – 787 IPM |

|

Wire Tension |

300 – 2,200 grams |

|

Start Hole Diameter |

0.020″ ∅ |

|

Max. Wire Spool Weight |

22 lbs. |

|

Positioning Accuracy |

0.00012″ |

|

Repeatability (XY) |

0.00008″ |

|

Total Power Required |

15 KVA |

|

Deionized Resin Tank |

935 0.4 cu/ft Fiberglass Bottle |

|

Tank Capacity |

220 Gallons |

|

Floor Space |

94″ x 108″ x 78″ |

|

CNC Control Screen |

21″ Color Monitor |

|

CNC Control Device |

ueX10 Windows 10 PC |

|

Weight |

5,830 lbs. |