Accutex AU-iA Series – Fixed Table Moving Column Submerged-Type Extra Large Capacity Wire EDM

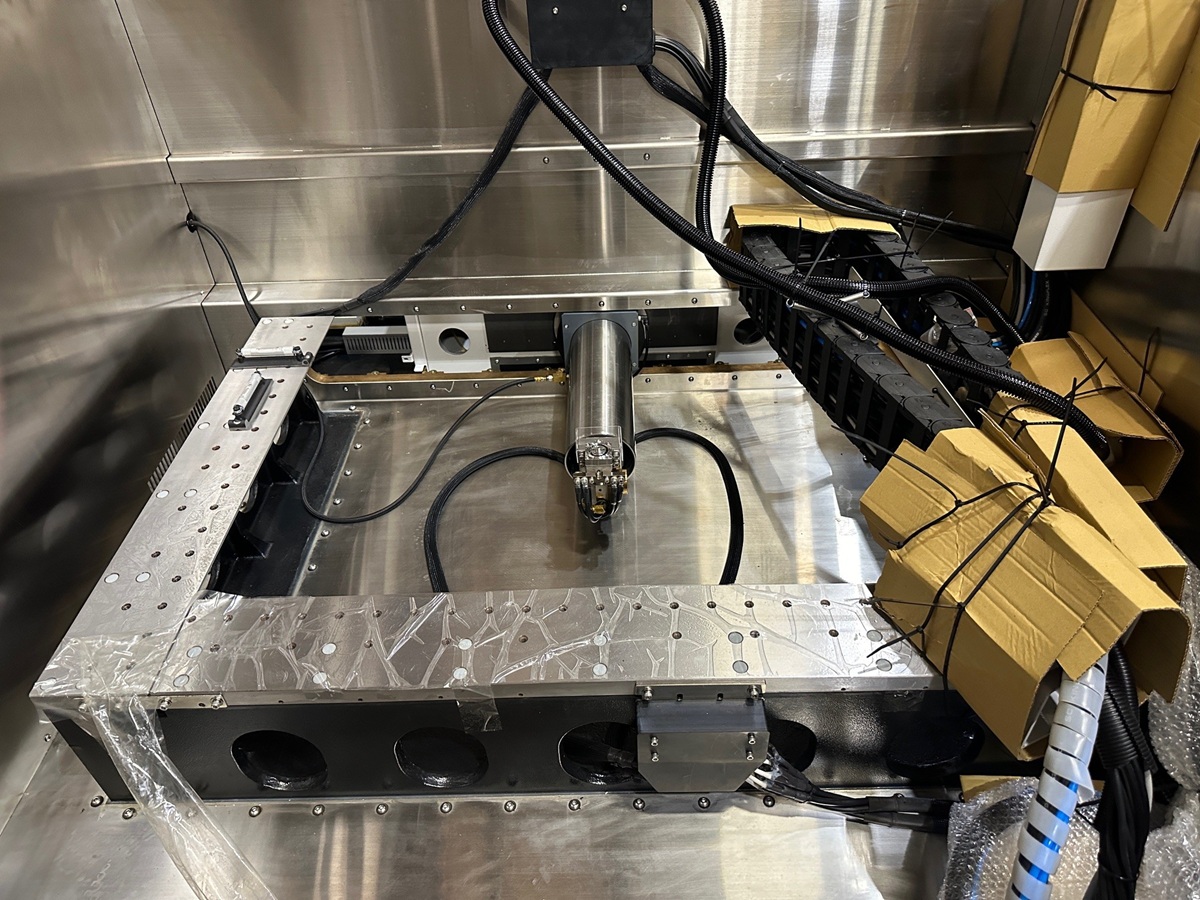

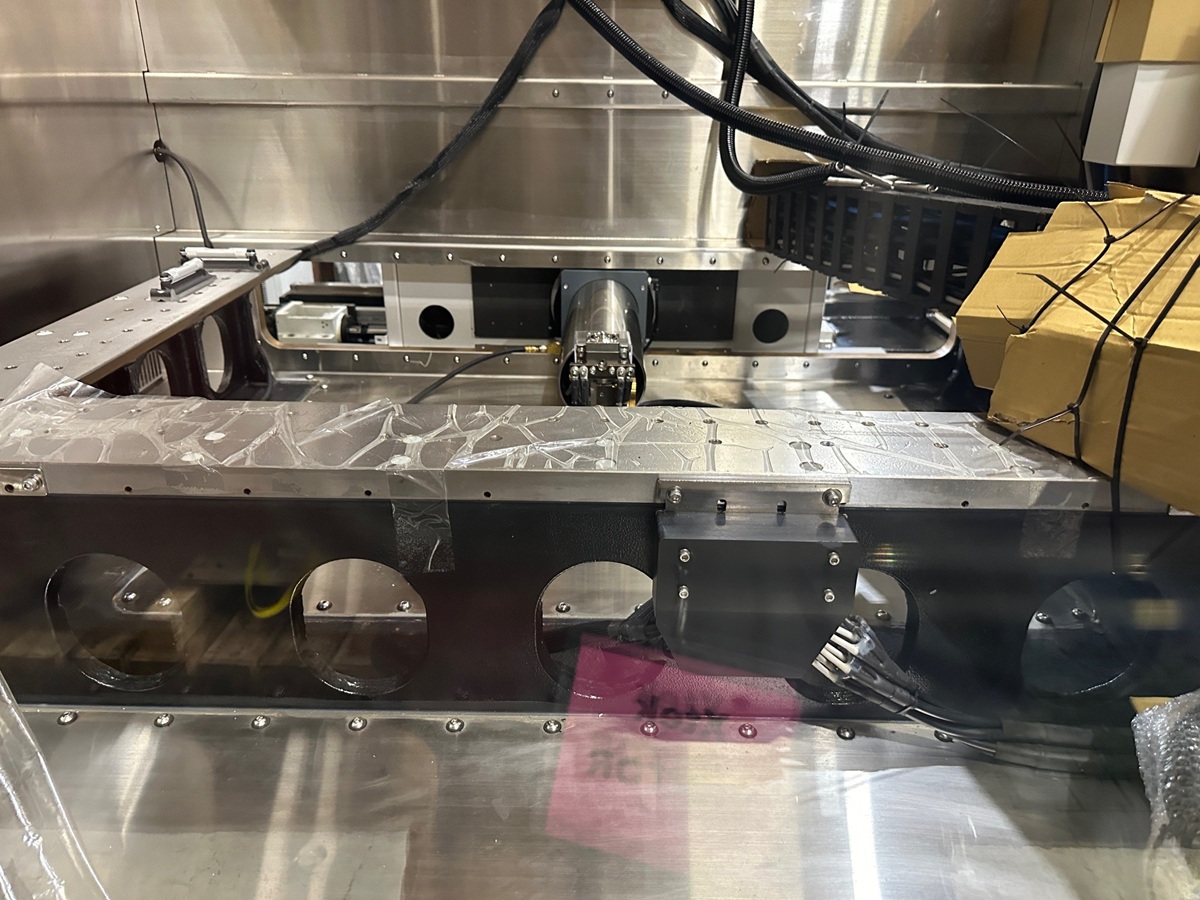

The AccuteX AU-iA Series are large fixed-table, submerged-type, extra-large capacity wire EDM machines designed to handle heavy workpieces with exceptional cutting performance and precision. Uncommon in today’s market, the AU-iA Series delivers massive-scale capacity and features automatic wire threading over the full stroke, accommodating workpieces up to 31.3 inches in height.

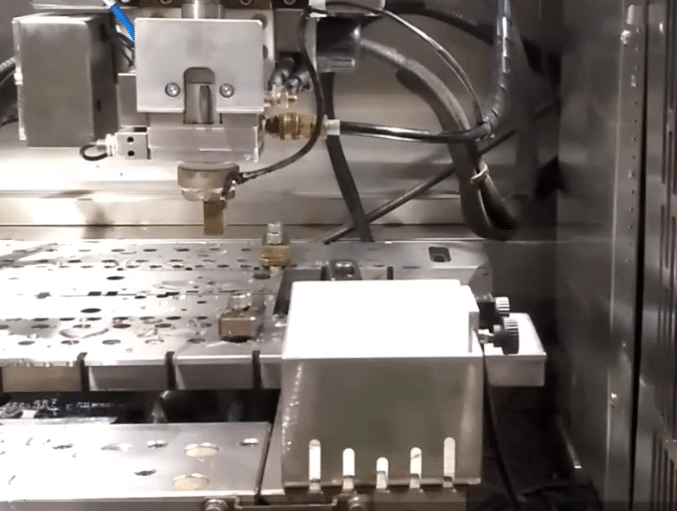

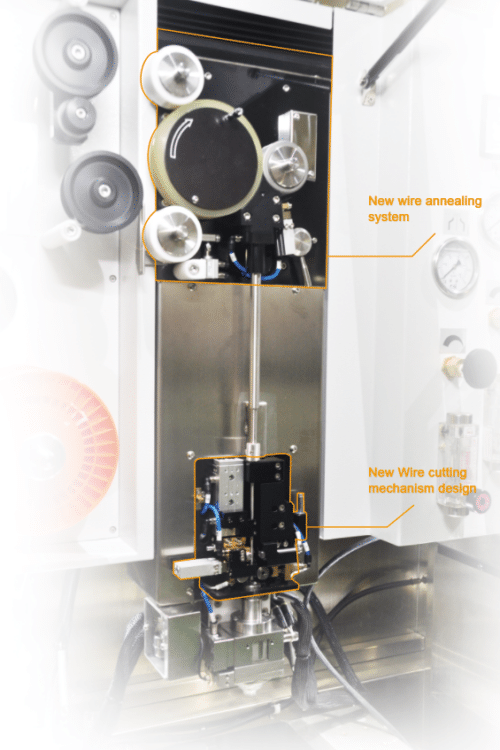

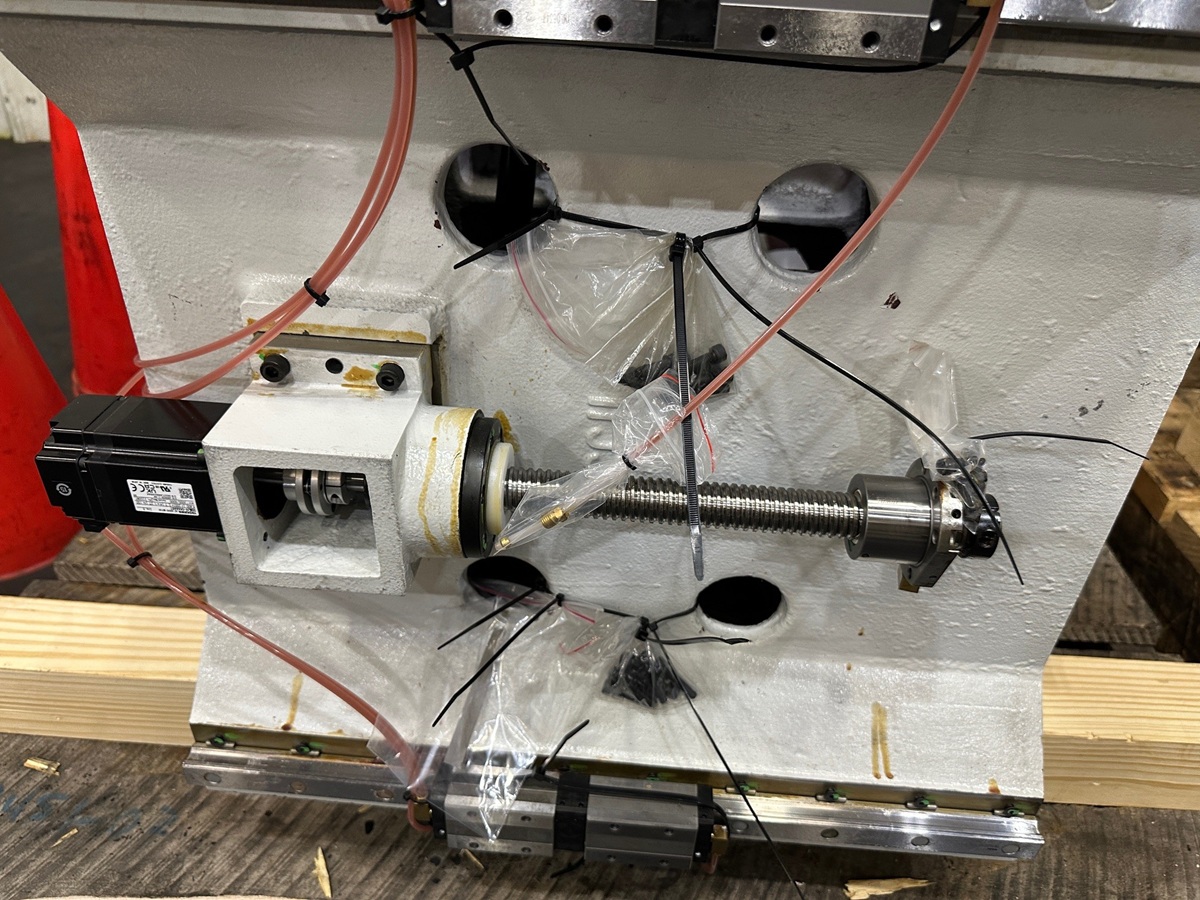

Each machine is designed using Finite Element Analysis (FEA) for maximum structural integrity, featuring a Meehanite honeycomb-type base, heavily ribbed column, and reinforced lower arm that ensure rigidity and long-term accuracy under heavy-load conditions. Combined with AccuteX’s Intelligent AWT system, C1-class ball screws, and linear glass-scale feedback, the AU-iA Series achieves sub-micron precision, ultra-fine surface finishes, and reliable unmanned operation for demanding aerospace, medical, and mold & die applications. Competing directly with Mitsubishi, Makino, GF Machining Solutions, Sodick, and Fanuc, AccuteX offers a powerful, cost-effective alternative for precision EDM manufacturing.

Key Features

- Large fixed-table, submerged-type design for heavy workpieces up to 31.3″ tall

- FEA-optimized Meehanite honeycomb base for rigidity and vibration damping

- Oversized UVZ axes with C1-class ball screws and reinforced lower arm

- Hiwin linear guideways for smooth, low-friction motion

- Fully closed-loop servo control with 0.000008″ feedback resolution

- ±45° taper cutting capability (optional wide-angle guides)

- Intelligent AWT System with annealing and scrap-wire disposal

- SD Master EPGA discharge circuit for stable spark control and fine finishes

- 64-bit Windows CE CNC control with 15″ color touch screen

- Ergonomic swivel operator panel with USB, Ethernet, and RS-232C ports

- Dual dielectric system with automatic temperature and conductivity control

- Optional W-axis rotary table for multi-face or cylindrical machining

Specifications

| Item / Model |

AU-860iA

Request a Quote

|

AU-1000iA

Request a Quote

|

AU1000iA+Z800

Request a Quote

|

AU-1400iA

Request a Quote

|

AU-1400iA+Z800

Request a Quote

|

|---|---|---|---|---|---|

|

X Axis Travel |

31.5″ |

43.3″ |

63.7″ |

55.1″ |

55.1″ |

|

Y Axis Travel |

23.6″ |

25.6″ |

39.8″ |

31.5″ |

31.5″ |

|

Z Axis Travel |

15.75″ (23.6″ opt.) |

15.75″ (23.6″ opt.) |

31.3″ |

7.9″ |

31.5″ |

|

U Axis Travel |

5.9″ |

5.9″ |

5.9″ |

5.9″ |

5.9″ |

|

V Axis Travel |

5.9″ |

5.9″ |

5.9″ |

5.9″ |

5.9″ |

|

Table Feed Rate |

40.0 IPM |

40.0 IPM |

40.0 IPM |

40.0 IPM |

40.0 IPM |

|

Max. Taper Angle |

±45° |

±45° |

±45° |

±45° |

±45° |

|

Max. Workpiece (XYZ) |

52.4″ x 39.8″ x 15.55″ |

63.78″ x 39.8″ x 15.55″ |

63.78″ x 39.8″ x 15.55″ |

68.5″ x 42.5″ x 7.7″ |

70.5″ x 42.5″ x 31.3″ |

|

Max. Workpiece Weight |

11,000 lbs. |

11,700 lbs. |

11,700 lbs. |

8,800 lbs. |

22,000 lbs. |

|

Wire Diameter |

0.008″ – 0.013″ |

0.008″ – 0.013″ |

0.008″ – 0.013″ |

0.006″ – 0.013″ |

0.006″ – 0.013″ |

|

Wire Spool Feed Rate |

60 – 787 IPM |

60 – 787 IPM |

60 – 787 IPM |

60 – 787 IPM |

60 – 787 IPM |

|

Wire Tension |

300 – 2,200 grams |

300 – 2,200 grams |

300 – 2,200 grams |

300 – 2,200 grams |

300 – 2,200 |

|

Start Hole Diameter |

0.020″ ∅ |

0.020″ ∅ |

0.020″ ∅ |

0.020″ ∅ |

0.020″ ∅ |

|

Max. Wire Spool Weight |

35 lbs. |

35 lbs. |

35 lbs. |

35 lbs. |

35 lbs. |

|

Positioning Accuracy |

±0.00016″ |

±0.00016″ |

±0.00016″ |

±0.00016″ |

±0.00020″ |

|

Repeatability |

±0.00010″ |

±0.00010″ |

±0.00010″ |

±0.00010″ |

±0.00010″ |

|

Total Power Required |

15 KVA |

15 KVA |

15 KVA |

15 KVA |

15 KVA |

|

Deionized Resin Tank |

935 0.4 Cubic Ft. Fiberglass Bottle |

935 0.4 Cubic Ft. Fiberglass Bottle |

935 0.4 Cubic Ft. Fiberglass Bottle |

935 0.4 Cubic Ft. Fiberglass Bottle |

935 0.4 Cubic Ft. Fiberglass Bottle |

|

Tank Capacity |

705 Gallons |

768 Gallons |

770 Gallons |

640 Gallons |

910 Gallons |

|

Floor Space |

154″ x 142″ x 116″ |

172″ x 142″ x 116″ |

172″ x 142″ x 124″ |

167″ x 147″ x 97″ |

201″ x 160″ x 134″ |

|

CNC Control Screen |

15″ Color Touch |

15″ Color Touch |

15″ Color Touch |

15″ Color Touch |

15″ Color Touch |

|

CNC Control Device |

64-Bit Windows CE PC |

64-Bit Windows CE PC |

64-Bit Windows CE PC |

64-Bit Windows CE PC |

64-Bit Windows CE PC |

|

Weight |

14,300 lbs. |

18,700 lbs. |

18,850 lbs. |

18,920 lbs. |

20,900 lbs. |

Benefits for Metal Cutting Manufacturers

These benefits help manufacturers achieve higher part accuracy, reduced cycle times, and repeatable quality, maximizing throughput and profitability.