Press Releases

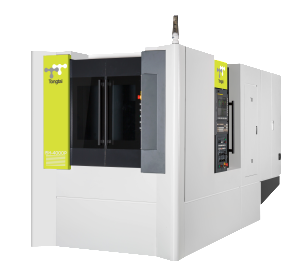

Tongtai’s NEW Ultrasonic iVU-5 Assisted Machining Center to debut at IMTS 2016 Booth S-8536

Tongtai’s brand new iVU-5 is a rotary assisted ultrasonic machining center that operates as a dual function vertical machining center combined with rotary ultrasonic assisted machining of advanced materials. Absolute Machine Tools will be unveiling this new machine in its IMTS 2016 booth S-8536.

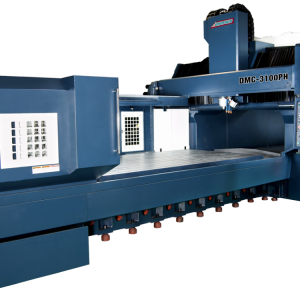

AT IMTS 2016 — Johnford DMC Series Bridge Mills Offer Large Load Handling with Maximum Stability in a Smaller, Expandable Footprint

Johnford DMC Series double-column moving table bridge mills are created from a one-piece Meehanite® cast iron bridge/column assembly that takes up 30 percent less floor space than comparable C-frame vertical machining centers. IMTS 2016 visitors can see this machine in action in booth S-8536.

Absolute Machine Tools, Inc., travels to Taiwan to Attend Tongtai Machine & Tool Company, Ltd.’s International Open House

Tongtai Machine & Tool Co. Ltd. hosted a worldwide open house, bringing together more than 1,000 of its customers, suppliers and media from around the world to its headquarters in Kaohsung, Taiwan recently to showcase the company’s commitment to R&D, innovation, technology application, and service. Its North American importer and distributor, Absolute Machine Tools, Inc., sent several of its sales and dealer teams to learn more about Tongtai in its native Taiwan.

Absolute Machine Tools Acquires Chicago-Area Distributor Machine Tool Technology-21

Absolute Machine Tools, Inc. has reached an agreement to acquire Chicago area distributor Machine Tool Technology – 21, Inc. (MTT-21) into its operations to better serve its customers in Illinois and Wisconsin.

New 4-Axis Vertical Turning Center for High-Volume Wheel Production and Similar Parts

The You Ji YV-600E2T Vertical Turning Center is designed for large lot-size machining of big aluminum wheels or similar parts. This compact, high-precision, heavy-duty machine is designed to operate as a stand-alone machining cell or to be integrated with other machines to form a complete flexible manufacturing system.

Introducing the Johnford SV-60H Vertical Machining Center – Large Load Handling for Heavy Cutting Applications

The Johnford SV-60H vertical machining center is capable of handling heavy cutting applications due to a large work envelope, a two-speed gearbox spindle, and all box way construction. The SV-60H’s C frame, constructed from heavily ribbed Meehanite FC-30 cast iron, is instrumental in eliminating vibration and ensuring smooth surface finishes and long cutting tool life.

Introducing the Tongtai CT-350 VMC – High-Speed Five-Axis Machining in a Small Footprint

The new CT-350 five-axis Vertical Machining Center from Tongtai features state-of-the-art performance in a small footprint. The CT-350 boasts high-end machine construction and performance at an affordable price.

Johnford DMC Series Bridge Mills Offer Large Load Handling with Maximum Stability in a Smaller Footprint

Johnford DMC Series double-column moving table bridge mill is created from a one-piece Meehanite® cast iron bridge/column assembly that takes up 30 percent less floor space than comparable C-frame vertical machining centers. Available in both moving table and sliding column (fixed-table) versions, the bridge mills have a long base casting with complete support of the table over the full 51 inches of Y-axis travel, allowing massive loads to be machined.

Absolute Machine Partners with ServiceMax for Improved Service Program

Absolute Machine Tools, Inc., has teamed up with ServiceMax, the leading field service software solution provider, to improve upon its ISO-certified Preventative Maintenance Program by offering customers answers to their service-related questions at any time. The ServiceMax cloud-based solution allows engineers and technicians access to a facility’s plant maintenance plan at all times via an iPad or Windows-based PC app, providing real time service and solutions to machinery breakdowns and other related problems.

Introducing the Tongtai SH-4000 HMC – FMS-Ready, Compact and Quick for Aluminum Alloy Parts Production

The New SH-4000 Horizontal Machining Center from Tongtai was developed for mass production line formation and fast aluminum alloy parts machining. The new compact machine has a 35% smaller footprint than the previous model, allowing for maximum shop floor utilization throughput. By integrating a robot on either a floor-type motion axis rail system or overhead gantry, manufacturers are able to catapult production and streamline manpower costs.