In the world of precision manufacturing, vertical and horizontal honing processes play a critical role in creating some of the most intricate and vital components. These methods are the unsung heroes in the manufacturing of high-quality gun barrels, a cornerstone in both the firearms and defense industries.

Precihole Machine Tools has spent the past 40 years perfecting the art of both vertical and horizontal honing processes for finishing a large range of bore sizes and lengths. For nearly 15 years, Absolute Machine Tools has partnered with Precihole to bring these machines to the North American manufacturing market.

How Vertical and Horizontal Honing Machines Elevate Firearm Manufacturing

Honing machines play a vital role in perfecting the interior surface of cylindrical shapes. In the firearm and defense industries, this precision honing is integral for preparing gun barrels for rifling, ensuring impeccable precision.

The quality of the surface texture, finish, and taper obtained through the honing process is outstanding. Vertical honing machines in particular are equipped to significantly improve the quality of gun barrels, enhancing their precision. This honing technique is often applied to bores or holes in a wide range of components.

Beyond defense, these honing processes are also critical in the energy, automotive, aerospace, and heavy machinery industries. Notably, they’re instrumental in the medical sector for components like small bone screws and rods.

In the firearm industry, vertical and horizontal honing machines are key to boosting the efficiency and reliability of firearm parts, including barrels. Here’s a guide to understand when to utilize each method:

When Vertical Honing Machines Are the Right Choice

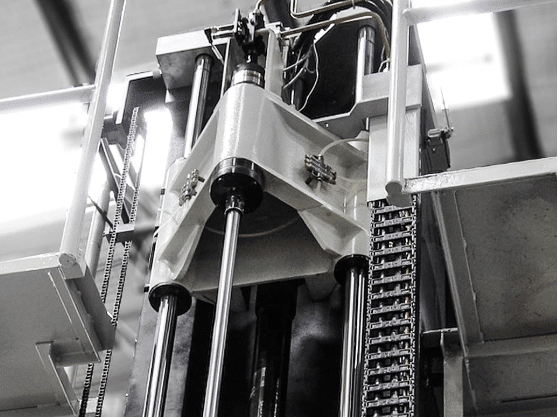

Vertical honing is typically chosen for components needing stringent adherence to specifications, such as long bores where maintaining straightness and uniformity is key. With Precihole’s precision tooling, these machines yield exceptionally smooth holes with submicron-level straightness, roundness, and cylindricity.

Gun Barrel Honing

In the context of firearms, vertical honing is essential for creating barrels with unparalleled accuracy. This process allows for the gun barrel to be mounted vertically, ensuring that honing is uniform across the entire length. This uniformity is critical for achieving consistent bore diameter and a smooth surface finish, which are key factors in enhancing the accuracy and performance of firearms. The precision in honing directly influences the bullet’s trajectory, making it a critical step in barrel manufacturing.

Chip Evacuation

The vertical orientation also offers a strategic advantage in chip evacuation. During the honing process, chips and debris are produced, and the vertical setup facilitates their efficient removal. This not only ensures a cleaner process but also contributes to the overall quality of the honing.

Applications Across Other Industries

Vertical honing is not just pivotal in firearm barrel manufacturing; it also has extensive applications across a wide range of industries:

These diverse applications underscore the versatility and importance of vertical honing in various sectors, beyond its critical role in firearm barrel manufacturing.

When Horizontal Honing Machines Are the Right Choice

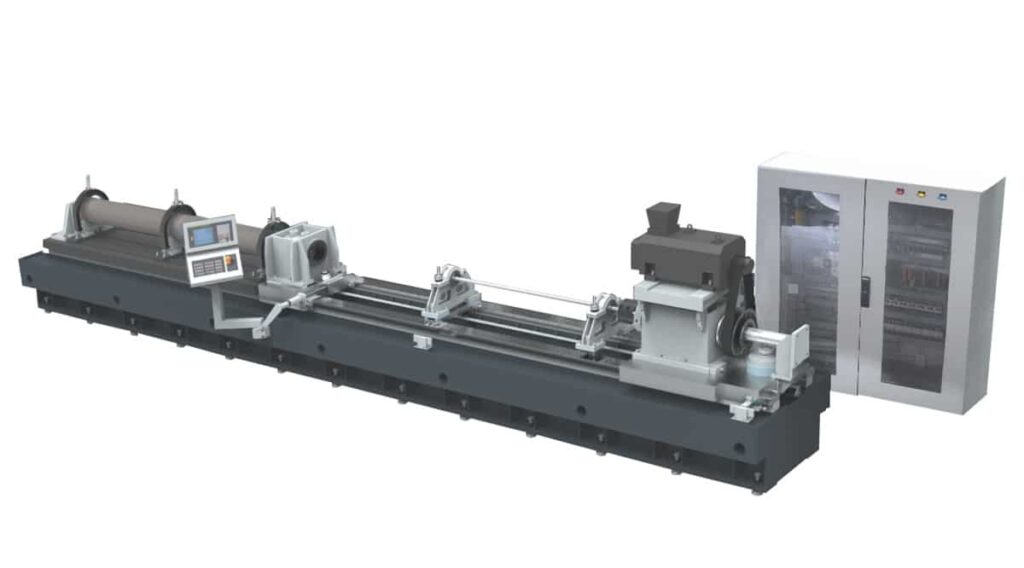

Horizontal honing is ideal for a range of cylindrical components, especially when the horizontal layout is more practical or the bore length is less critical. It’s notably efficient for large bore artillery barrels, offering ease of handling and flexibility for various components.

Large Bore Artillery Barrels

In the firearms industry, horizontal honing machines are particularly suited for large bore artillery barrels, ranging from φ30mm to φ205mm. These machines can accommodate barrel lengths up to 10,000mm, making them ideal for honing artillery pieces. The horizontal setup allows for fast loading and unloading, which is crucial when dealing with such large and heavy components.

Ease of Operation

The design of horizontal honing machines facilitates ease of handling for operators. This is especially important when working with heavy or unwieldy components, as it ensures efficiency and safety in the machining process.

Flexibility for Various Parts

These machines offer flexibility in honing various parts, making them suitable for different components that may not require a vertical setup. This adaptability is vital in industries that work with a diverse range of cylindrical parts.

Small Components

Horizontal honing is ideal for smaller firearm components such as cylinder bores and chambers. The horizontal orientation is often more suitable for parts that are easier to handle and process in this position.

Applications for a Wide Range of Industries

Horizontal honing has many applications outside of the firearms industry, including:

Precihole and Absolute Machine Tools – Your Partners in Precision Honing

Precihole Machine Tools stands as a leader in high-precision deep hole drilling and finishing technology. In partnership with Absolute Machine Tools, they offer innovative solutions tailored to the unique needs of the firearms and defense industries.

Together, we provide a comprehensive range of advanced drilling and finishing machines, backed by expert service and engineering support. This collaboration is at the forefront of technological advancement in deep hole drilling, continually pushing the boundaries of precision and quality.

For manufacturers seeking unparalleled precision in gun barrel production and other critical components, Absolute Machine Tools is the go-to partner for all deep hole drilling and deep hole finishing requirements. Contact us to learn more.