Vertical Turning Centers (VTCs) and Vertical Turning Lathes (VTLs) are like horizontal turning machines but stood up vertically. VTCs are fully enclosed compact systems designed for stand-alone applications or easy integration into production lines. These machines are ideal for manufacturers looking to expand production capabilities into castings, such as brake discs, pump housing, or aircraft parts.

Vertical turning centers and lathes are ideal for cutting large heavy workpieces for a variety of industries.

Vertical Turning Center Benefits

Vertical turning provides several benefits to manufacturers looking to expand their capabilities and tackle larger parts.

More Affordable, Quick ROI

First, the machines are more affordable than ever before – often approaching the cost of a conventional horizontal turning center. In addition, high demand for vertically turned parts from industries such as energy, aerospace, and construction ensure manufacturers see a quick return on investment.

Working With Gravity

The second advantage of vertical turning centers is that they work with gravity rather than fighting against it. With horizontal turning centers, operators must load, fight, and fixture heavy big parts. This adds time to the production cycle and can lead to operator injuries. With a vertical turning center, operators simply load the part on the table. Often, relatively light clamping holds the part in place. This is an important benefit when working with thin-walled parts where clamping can induce warpage.

Better Cycle Times

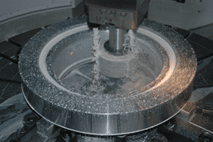

In terms of productivity, vertical turning centers typically improve cycle times because manufacturers can be more aggressive with their cuts. Why? Again, it’s Physics 101: Gravity helps hold parts on the table so manufacturers can use the full power of the machine to remove material.

Smaller Footprint

Vertical turning machines also take up less floor space than their horizontal counterparts. Manufacturers can place two machines closely together in a right/left configuration, essentially gaining twice the productivity of a horizontal turning center in the same sized footprint.

Manufacturers can do OP 10 on one vertical turning center and have the robot transfer the part to the other for OP 20.

More Productive

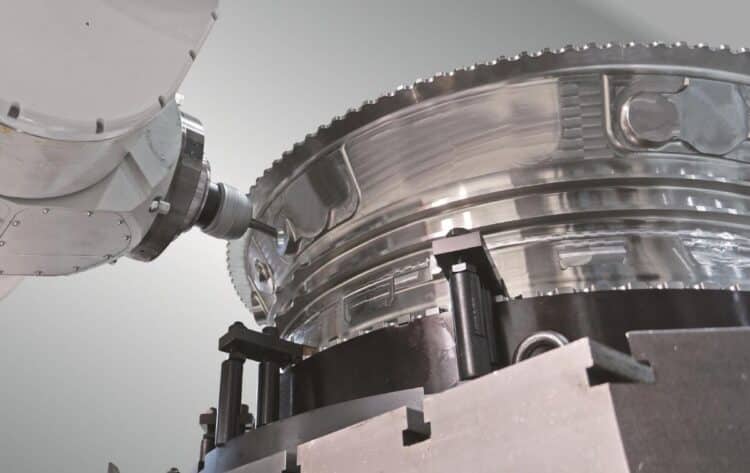

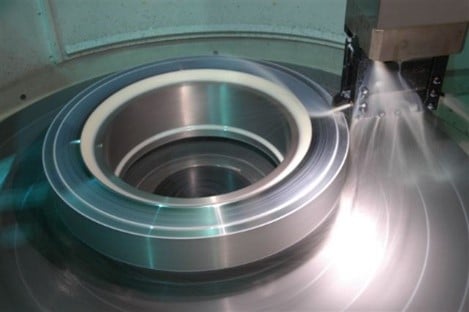

Live tooling also makes vertical turning more productive than ever. Manufacturers can mill, drill, and tap. They can even equip the machines with grinding wheels for deburring, and where tolerances are acceptable, for actual grinding operations. For complex milling, Y-axis is available on a variety of models. B-axis (tilting) heads are also available. The combination of these features can make the machine a 5-face or 5-axis milling machine for done-in-one capability.

A grinding attachment adds versatility to a You Ji VTL.

Product Offerings from Absolute Machine Tools

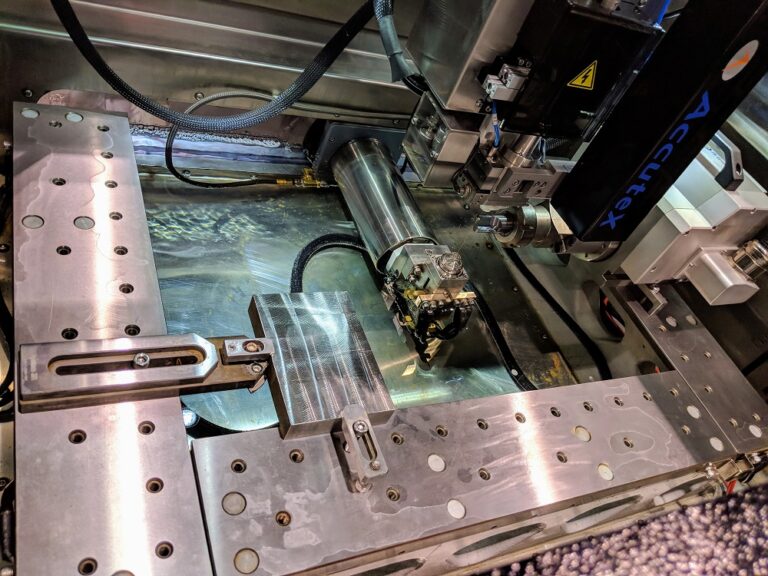

Absolute Machine Tools sells both Vertical Turning Centers (VTCs) and Vertical Turning Lathes (VTLs). These machines are quite different and are machines that serve separate markets.

Absolute’s You Ji vertical turning centers deliver productivity and precision in a single machine. They have a smaller footprint versus horizontal turning centers, and a very solid frame for superior finishes. Manufacturers with a limited amount of floor space can place two vertical turning centers closely together in a right/left configuration, essentially gaining twice the productivity of a horizontal turning center in the same sized footprint. You Ji VTCs are available with maximum swings ranging from 16” to 48” and cutting diameters from 10” to 40”.

Absolute’s larger You Ji vertical turning lathes are for heavy-duty high-power cutting of medium and large parts, particularly aerospace, construction, and energy applications. These machines are very rigid, featuring cast iron frames and box ways. They also boast geared table drives that generate tremendous torque. In addition, high horsepower spindle motors deliver high torque for heavy duty machining and high speeds for fine finishing. You Ji VTLs have maximum swings from 43.3” to 354” and cutting diameters from 41” to 350”.

Need to go bigger? Absolute also offers the VTH-8000, the largest vertical turning center on the market. The You Ji VTH-8000 is built with a 315” table, 354” max swing, and 350” cutting diameter.

Vertical Turning Technology

The key to machine performance is a rock-solid foundation. Therefore, manufacturers should seek out vertical turning centers that are strong, stable, and extremely rigid to ensure the best performance for turning large parts. Machines should be heavily weighted with cast iron construction that damps vibration. Rams and columns should be built strong to withstand heavy duty cutting forces.

Ready to take your manufacturing to the next level? Contact Absolute Machine Tools today to discuss your vertical turning needs!