The aerospace industry is synonymous with groundbreaking innovation, precision engineering, and pushing the boundaries of what is possible. At the heart of this industry’s success lies the critical role played by machine tools. These advanced manufacturing systems are instrumental in producing the intricate components and structures that power modern aircraft. In this blog post, we will explore the crucial role of machine tools in the aerospace industry, highlighting their impact on precision, efficiency, and innovation.

Precision Engineering for Aerospace Components

Precision is non-negotiable in aerospace manufacturing, where even the smallest deviation can have significant consequences. Machine tools deliver exceptional precision, enabling the creation of intricate components with tight tolerances. From turbine blades and aircraft frames to landing gear and control surfaces, machine tools provide the accuracy required to meet the industry’s stringent standards.

With our deep understanding of the aerospace industry, Absolute Machine Tools offers a range of cutting-edge machine tools designed to meet the demands of precision engineering. Our machines incorporate advanced features such as high-speed machining, multi-axis capabilities, and superior control systems, ensuring that your aerospace components are manufactured to the highest degree of accuracy.

Driving Efficiency and Productivity

Efficiency is paramount in aerospace manufacturing, where strict deadlines and cost considerations are constant challenges. Machine tools enable high-speed and high-volume production, significantly reducing manufacturing times. Advanced automation features, such as robotic loading and unloading, further enhance productivity by minimizing downtime and maximizing machine utilization.

At Absolute Machine Tools, we understand the importance of efficiency in aerospace manufacturing. Our range of machine tools is optimized for speed, reliability, and automation, empowering you to streamline your production processes and meet demanding delivery schedules. By partnering with us, you gain access to cutting-edge technology designed to enhance your operational efficiency.

Enabling Innovation and Advancements

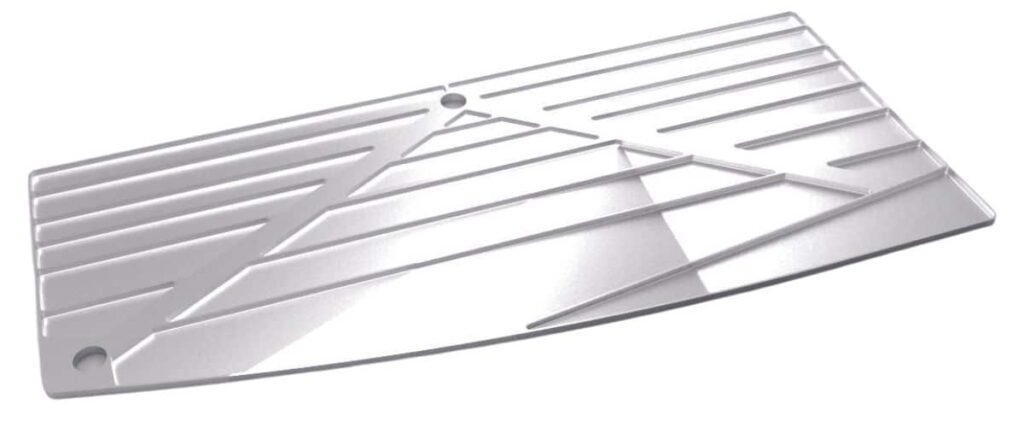

The aerospace industry thrives on innovation, constantly pushing the boundaries of what is possible. Machine tools play a pivotal role in enabling this innovation by facilitating the development of new materials, advanced designs, and novel manufacturing techniques. From 3D printing and composite machining to complex 5-axis machining, machine tools empower aerospace manufacturers to explore new frontiers.

As a leading provider of machine tools, Absolute Machine Tools is committed to fueling innovation in the aerospace industry. Our machines are at the forefront of technological advancements, offering features like additive manufacturing capabilities and multi-tasking functionalities. By leveraging our cutting-edge equipment, you can stay at the forefront of aerospace innovation.

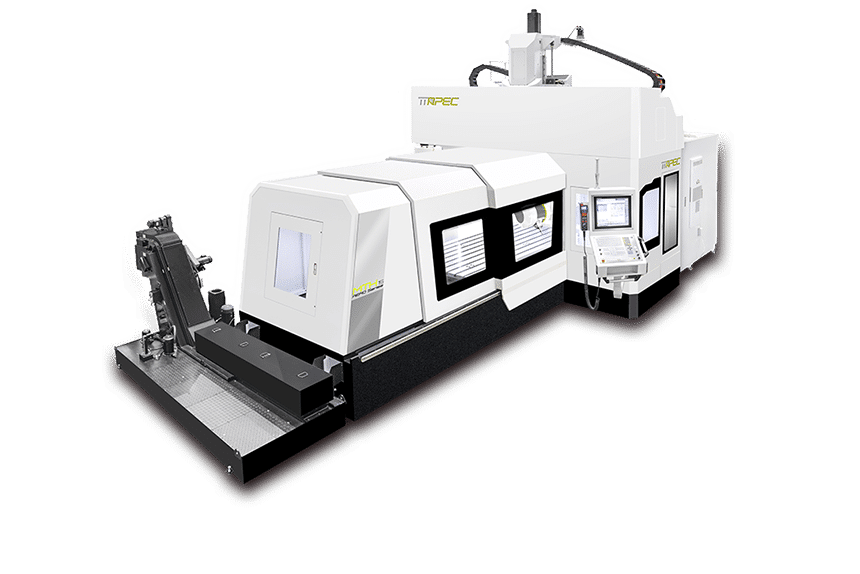

APEC Machines Designed Specifically for Aerospace

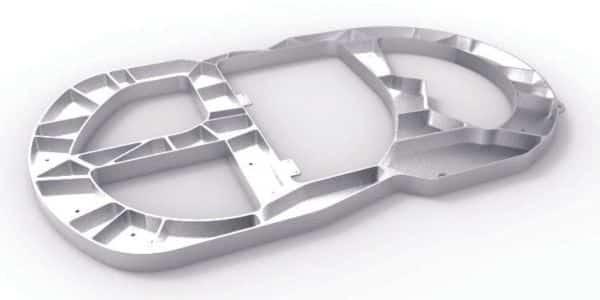

The APEC MTH15RT 5-axis aircraft turbine engine casing machining bridge mill center is specifically designed for high-tensile titanium and super alloy parts.

The APEC SK 5-axis high speed gantry machining center is specifically designed for complete machining of aluminum parts for the aerospace industry.

The APEC SKM 5-axis high speed gantry machining center is similar to the SK-5 Series but employs Box-in-Box structure features, full force flow and thermal symmetry, along with DCG (driving at the center of gravity). The DCG is an excellent feature that improves surface finish.

Bombardier Inc. & the APEC CM4050 5-Axis High-Speed Gantry Machining Center

Founded in 1942, Bombardier manufacturers both airplanes and locomotives, and is considered to be one of the largest airplane manufacturers in the world. APEC began it’s partnership with Bombardier in 2018 and is one of only a limited few Asian machine tool builders approved as a supplier to their world-class supply chain.

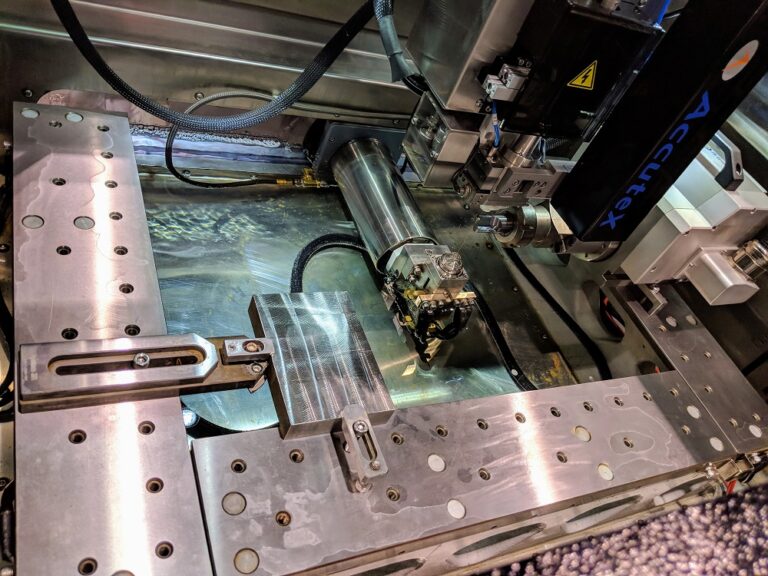

Together, Bombardier and APEC designed and developed the CM4050, a 5-axis high speed gantry-style machining center dedicated to machining aerospace composite components. These machines are also equipped with a special highly efficient dust collecting and filtering system, ensuring a clean work envelope both around the part and at the spindle nose.

The top of the machine is also equipped with a special sliding cover that is used to prevent oil mist and dust from spreading beyond the processing area ensuring operator health and good air quality throughout the rest of the facility.

Thyssenkrupp Aerospace UK Ltd. & the APEC G2560+G3030 5-Axis High-Speed Gantry Machining Centers

Thyssenkrupp Aerospace is an important partner to some of the world’s largest airplane manufacturers including Boeing, Rolls-Royce and Bombardier Aerospace. Like Bombardier, APEC is an approved supplier to the Thyssenkrupp Aerospace component supply chain.

Thyssenkrupp invested in both an APEC G2560 and APEC G3020 machining center to reduce processing hours while still maintaining the highest quality component production possible. The APEC G Series of 5-axis high-speed gantry-style machining centers is unique with its casting-made saddle, ram, and base ensuring extremely high stability and rigidity throughout the component part-making process. It’s one-piece U-shaped structure facilitates the shortest transmission of force flow while evenly distributing cutting forces and dampening vibration for parts requiring the highest of standards in the aerospace industry for finish and tolerance.

Learn More About Our Advanced Aerospace Manufacturing Solutions

Absolute Machine Tools knows that machine tools are the backbone of the aerospace industry, and are dedicated to providing you with state-of-the-art equipment designed specifically for aerospace applications. Contact us today to explore our range of machines and experience the transformative power they bring to the aerospace industr