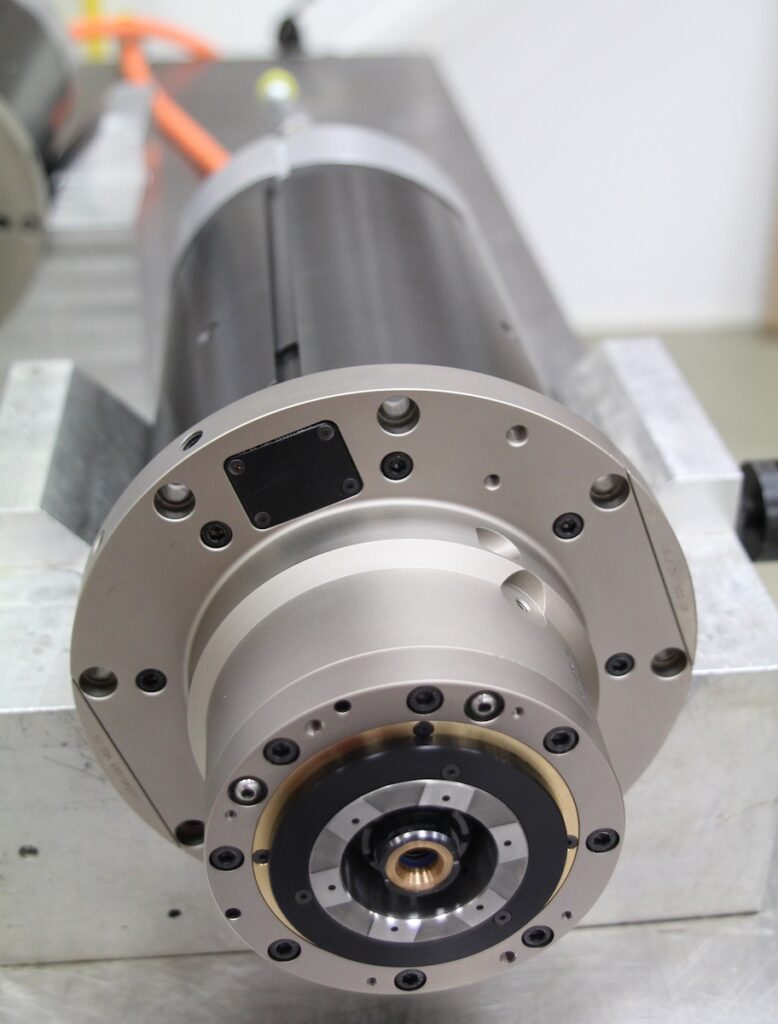

In September, Absolute Machine Tools partner PCI-SCEMM introduced at EMO 2019 a new electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality.

The e-SPINDLE was developed in France in collaboration with the Technical Centre for Mechanical Industry (Cetim) and the Aix-en-Provence campus of the French Arts et Métiers engineering and research graduate school.

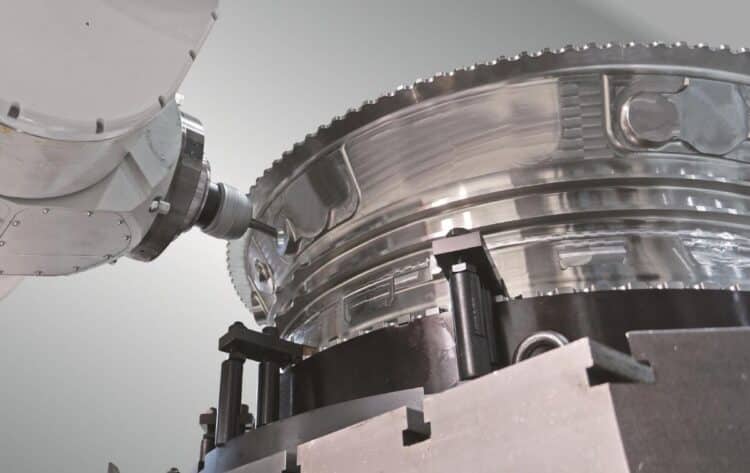

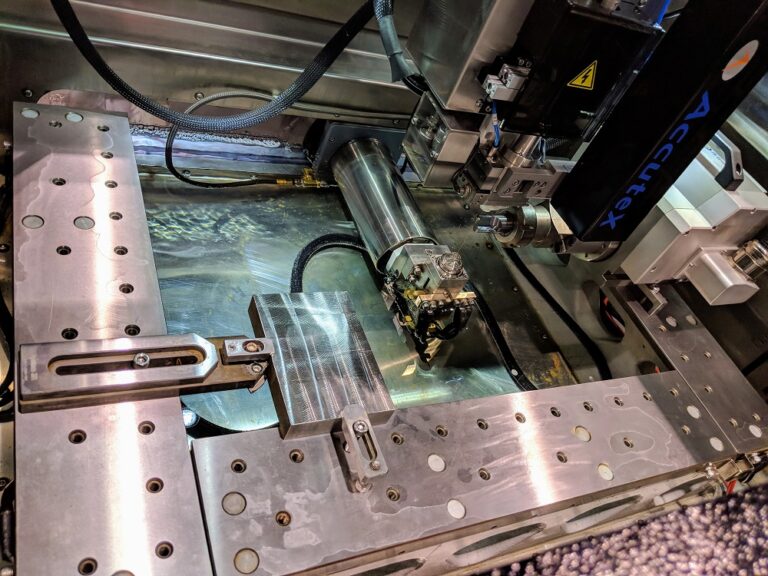

At the show in Hannover, Germany, PCI demonstrated three e-SPINDLE applications that showcased smart machining technology:

“e-SPINDLE technology from PCI is another way Absolute Machine Tools enables its customers to participate fully in smart manufacturing, the IIoT, and Industry 4.0,” said Absolute Machine Tools president Steve Ortner.

About PCI

Based in Saint-Etienne, France, PCI-SCEMM (a Tongtai company) manufactures CNC machine tools, with a focus on providing manufacturers with:

Absolute Machine Tools works with PCI to provide North American manufacturers with the most technologically advanced engineering solutions available. Our relationship with PCI and Tongtai allows us to provide the most valuable options and cost-effective solutions to boost profitability for even the largest and most demanding end-customers.