Absolute Machine Tools is proud to introduce the NEW Accutex GA Series linear motor CNC wire EDM machines with NEW ueX10 CNC control. The new GA series is like the previous GE series except for the new ueX10 CNC control. The ueX10 control is a result of a 5-year development project between Accutex EDM (Taiwan) and Absolute Machine Tools.

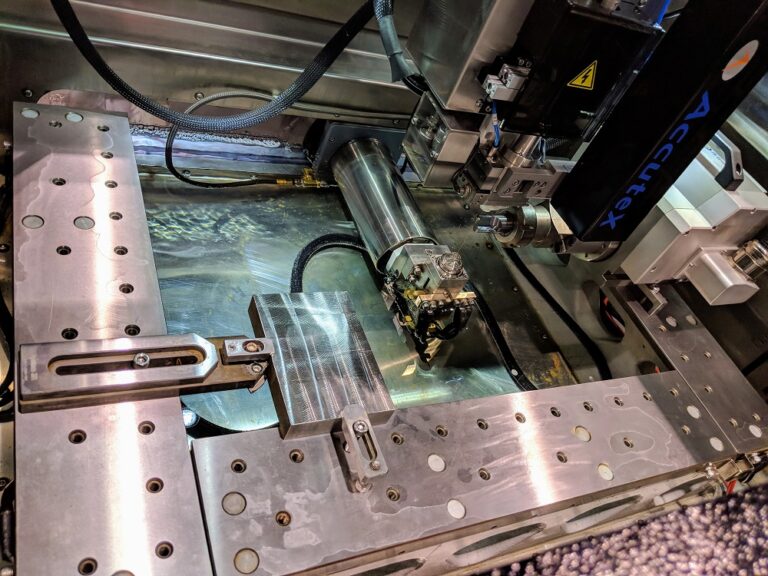

The new Accutex GA series employs an ergonomic space saving design, drop door, 3-sided table (back rail optional), patented fully annealing automatic wire threader and submerged machining capabilities of up to 8″ or 195mm. All GA series machines are available in both traditional ballscrew-style and linear motor motion systems.

Wire EDM CNC Control Design Focuses on User Experience

The new ueX10 CNC control is designed with a “USER-EXPERIENCE” focus that is advantageous for new and experienced operators and allows manufacturers the ability to remain current in Industry 4.0 and beyond. Running on a Microsoft OS platform, the ueX10 is more user friendly than most CNC controls in the market today.

This control easily integrates with the latest technical advancements in EDM machining. Using a 21″ touch screen and Windows 10 OS, the ueX10 is fully supported and will be easily updated with future Windows Operating Systems. The ueX10 features cloud-based applications, automation, and network monitoring to provide an all-in-one package for manufacturers.

The NEW ueX10 Wire EDM CNC control was designed with improvements such as:

Motor Torque Monitoring System

A 100% automatic torque measuring function that ensures interference-free smooth motion over the full stroke of the machine.

Processing History Library

Detailed recording of items such as speed, gap voltage, and other machining details critical to overall performance especially corner and arc processing.

Fast Simulation Performance

Ultra-fast simulation with 2D or 3D rendering of large NC programs allows the operator to inspect program paths efficiently and thoroughly, verifying accurate toolpaths from post processing.

Built-in Delta CAD/CAM Onboard

This feature comes standard with quick user-friendly geometry creation so operators can go from print to program in minutes. Full network and cloud capable CAD files can now be uploaded with toolpaths for highly efficient and flexible use on the shop floor.

Automatic Alignment Templates

The automatic alignment templates allow the user to preconfigure calibration and part alignment operations that can be saved and selected for future redundant tasks. Using these proven templates increases productivity and dramatically reduces operator error across operators and shifts.

Integrated EtherCAT Motion Control

EthertCAT is a fieldbus that meets the needs of standard high-performance industrial communication protocols based on an Ethernet network. Another way to describe EtherCAT is that it is the latest and greatest way to control machine tool drive motion.

EtherCAT offers exceptional performance with flexibility through multiple connections to servo drives, integrated safety features for network architecture, simple to integrate yet robust, and reduces the cost of hardware and repair. Another attribute is the use of the Linux OS to drive the EtherCAT. The Linux kernel is a widely ported operating system kernel, available for devices ranging from mobile phones to supercomputers, and is the perfect choice for stable high-speed use in industrial applications.

Learn More About the Accutex GA Series

For more information or a quote on the latest Accutex EDM GA series CNC wire EDM machines with ueX10 CNC control, email Absolute Machine Tools at info@absolutemachine.com or call 800-852-7825.