IMTS 2018 is rapidly approaching, and with more than 2,000 exhibiting companies, we know your week will be busy. We want you to know a few of the reasons why Absolute Machine Tools Booth 338536, South Building, should be at the top of your list to visit!

Here are a few of the demos we have lined up for IMTS:

Showing Our Creative Side

Today’s tradeshow exhibits have evolved into a far more creative beast than in past decades, and it’s a trend that Absolute is embracing. At the center of our IMTS booth will be a massive screen that is sized and shaped to replicate the front of a Meteor-brand 5-axis machine from PCI.

PCI is a French company owned by Absolute partner Tongtai (formerly Hitachi Seiki OEM). On-screen “doors” will open to reveal a video that presents two horizontally mounted spindles processing different parts independently.

Consolidation is Key

The Meteor demo isn’t the only demonstration to showcase the trend toward consolidating operations onto fewer platforms. Other demos at our booth will show how multi-slide CNC screw machines can offer a cost-effective alternative to multi-spindle machines.

With three tools in the cut at the same time (two OD tools and one ID tool), this process ensures efficiency and prolongs tool life in these difficult applications.

In one, a fitting typically made on a multi-spindle machine is instead produced on a LICO multi-slide CNC screw machine. This machine is capable of cutting with three tools at once, which reduces costs while maintaining the same cycle time. On another LICO machine, drills and reamers from Dayton, Ohio-based Greene Tool Systems, Inc. will create accurate square corners in a simultaneous drilling and pinch-turning process.

Ideal Geometry

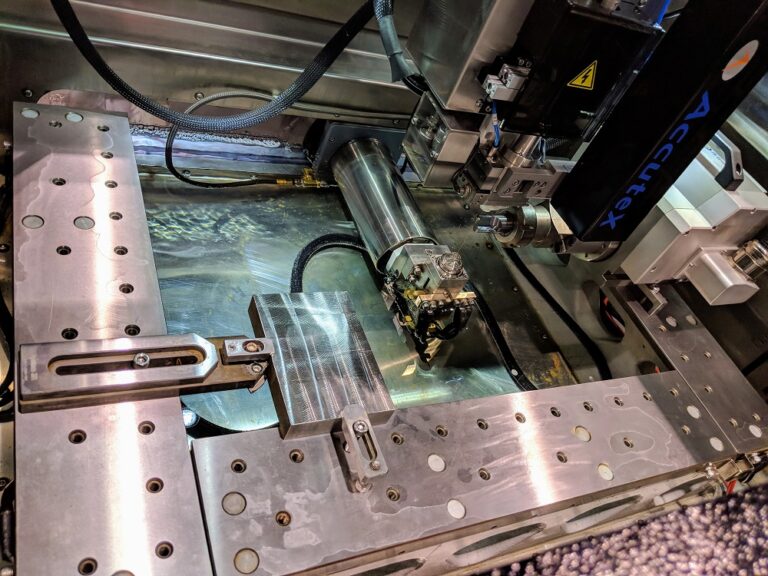

Another demonstration involves the AccuteX AL-600SA wire EDM. At the center of this profile-cutting process is not a paper blueprint, but a 3D model representing the ideal geometry of a solid carbide cutting tool inserted with polycrystalline diamond (PCD).

First, the operator uses a macro in Esprit CAM software to program an on-board Marposs probe to take data from select points on the part. Comparing the real-world part to the virtual ideal reveals the inherent surface inaccuracies that result from the PCD brazing process.

From there, the conversational macro uses the probe data to guide the operator through wire-path adjustments that ensure the real-world cutter matches its digital twin.

Happy 30th, Absolute!

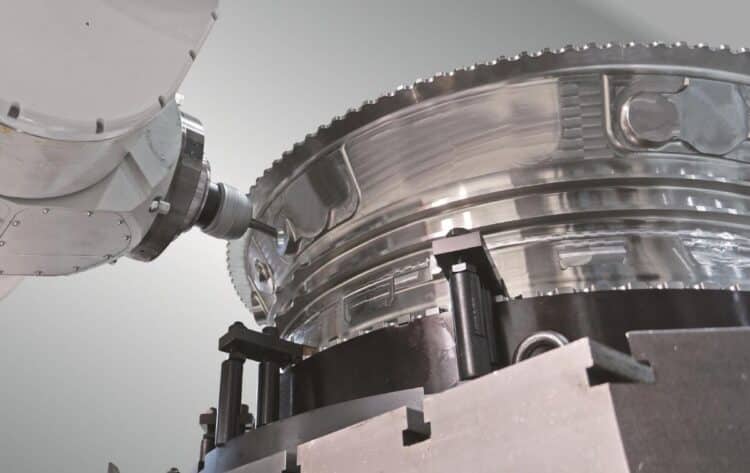

Of all the demos we have lined up, this one is a little special to us. In honor of our 30th year in the machine tool industry, a Tongtai SH-4000P horizontal machining center will cut a 6-inch-wide, 10-inch-high 30th anniversary logo that will decorate our four North American Technical Centers.

Fittingly for an era when importing and distributing machines requires automation expertise, the application utilizes a pallet changer and dual tombstones to rotate the aluminum blocks to a 45-degree angle.

Click here to learn more about what to expect from Absolute Machine Tools at IMTS 2018, the 32nd edition of the premier manufacturing technology show in North America!