Why is the C-frame VMC is not as useful as a bridge mill or gantry mill?

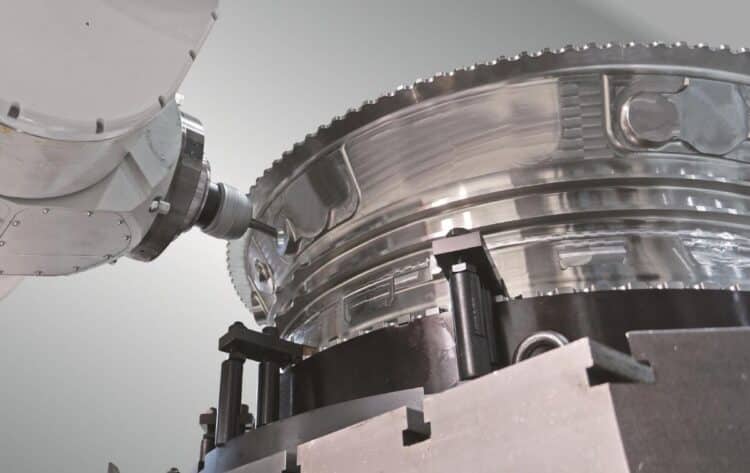

1. Ergonomics is a big issue (as pictured here) and so is safety.

On a CNC bridge mill, the part can be mounted anywhere on the table and multiple workpieces can be set up at one time. The C-frame design is not as flexible because you have limited access to the table.

2. The spindle — thus the cutting tool — is supported by two columns on a bridge or gantry mill instead of one column on a VMC.

The spindle centerline is very close to the Y axis on a CNC bridge mill, as opposed to the spindle centerline, which is a long distance away from the column on a C-frame vertical machining center. This greatly increases the rigidity and stability of the machine tool to significantly reduce vibrations, tool deflection and, thereby, hold tighter tolerances while enabling the machine to operate at optimum spindle speeds.

3. Chip removal is clearly superior on a CNC bridge mill.

Virtually all chips cleanly exit the machine with very little manual cleaning. A large VMC is inherently not as cleanly. Manual cleaning is necessary.

4. The closer the spindle is to the column of the machine, the higher the machine accuracy.

Because the table can move between the columns on a CNC bridge mill, the cutting forces are more stable. On a single column VMC design, stability is more difficult to achieve because the Z axis slide is further away from the spindle and the cutting point.

5. Dual column designs reduce vibration, resulting in less wear on machine tool components.

This can save a company a lot of money by avoiding future costly repairs and maintenance. And who doesn’t like to save money??

6. A C-frame VMC is less expensive but not as versatile.

A C-frame VMC may cost slightly less than a dual column bridge mill, but the ergonomics and versatility of a bridge mill machine is a huge advantage because you can run a multitude of part types more efficiently. Improved efficiency means higher production and bigger profits!

7. CNC bridge mills consume 40% less floor space than a similar size VMC.

Floor space is expensive. Save money with a bridge mill machine.