In its July issue, Production Machining magazine recognized the young talent in the precision machined parts industry. These men and women are making strides in shaping the future of our industry, and we’re pleased that our own Phillip Judt was among those recognized!

Phillip is an applications engineer here at Absolute Machine Tools who got his first experience in the production turning industry working as a front-line machinist at a Swiss machine shop. He then became an Applications Engineer in the Swiss turning industry before going back to the job shop world, running both CNC Swiss and CNC fixed headstock screw machines.

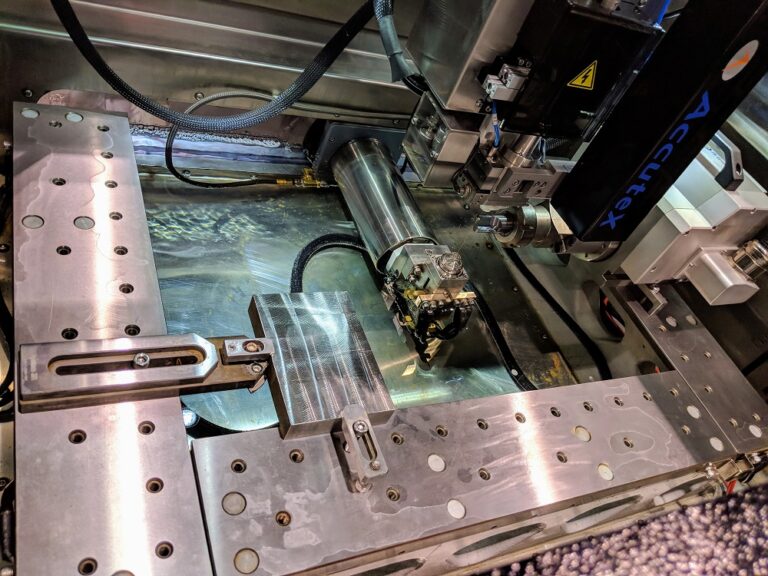

Upon joining the team at Absolute Machine Tools, Phillip has been exposed to an even wider variety of CNC screw machines. He demonstrates to customers the advantages and disadvantages of various modern methods of production machining and has been instrumental in assisting companies to advance from cam-operated equipment to new, productive CNC screw machines, becoming more profitable as a result. Phillip has demonstrated to many customers who would typically run a part on our Nexturn Swiss machines that those parts may be a better fit on a fixed headstock, CNC screw machine.

He added QuickTECH hybrid mill/turn centers to his repertoire and now has multiple solutions that can fit almost any production needs. The QuickTECH machines excel at parts that require more live tooling than most CNC fixed headstock machines can provide.

Knowing the nuances of these machines is critical to Phillip’s job of helping to advance the precision production industry. He is accomplished at applying and teaching the principles of overlapping tools, both on sliding headstock and fixed headstock CNC machines. Today, Phillip provides training for programming, setup, and operation of sliding and fixed headstock, multi-axis, multi-slide equipment and CNC mill/turn centers to all our production turning customers. The experience and knowledge in these applied practices have allowed him to demonstrate his comprehensive machining background, which has helped customers explore the best possible methods for processing parts.

Phillip understands that transition is not always easy, and having someone with his level of experience and knowledge is a tremendous asset that is vital to our customers’ futures. We are proud that he is a part of our team!