Absolute Machine Tools’ vice president of sales, Klaus Miller, recently shared insights about bridge mills in Advanced Manufacturing article “Bridge Mills: A Bridge to Success”.

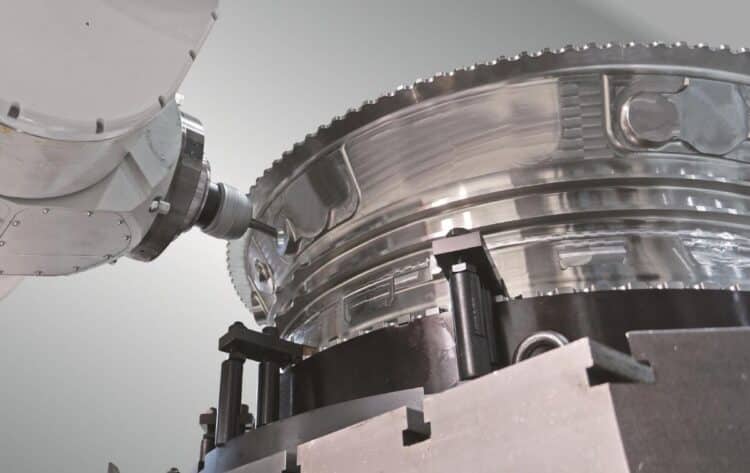

In the article, Miller discusses the benefits of bridge mills versus C-frame vertical machining centers, noting that the higher vibration levels in a C-frame machine wreak havoc on tool life, spindle bearings and other moving components.

“I don’t think most people recognize this. They try to take the same depths of cut and feed rates as they would on a bridge mill, which can take a far heavier beating. Because of that, we find there’s a lot more maintenance on a standard C-frame type VMC [than on a bridge mill].”

In addition to providing improved rigidity and thermal stability; better tool life and part quality; and increased metal removal rates, Miller also noted that bridge mills offer superior chip flow. This can eliminate hours of manual shoveling and cleaning each week. He also says that bridge mills are more flexible, because the operator can mount parts anywhere on the table and still have easy access.

Miller also shared a recent customer success story from a job shop in Dayton, Ohio, which has a dozen or so C-frame verticals. “The owner told me during a recent sales call that he would never purchase another one after investing in a Johnford DMC-2100H machining center,” he said. “From the standpoints of ergonomics, maintenance costs, and overall rigidity, [the owner] said there was simply no comparison.”

Finally, Miller noted that shipping costs are helping to narrow the price gap between bridge mills and VMCs.

“The ocean container for a C-frame VMC is quite wide, which due to the recent increases in ocean freight means a significant increase on the sticker price over a double-column machine. In fact, for the first time ever, we’ve begun ordering small DMC-series machines such as the DMC 1200H and 1500H for stock. Part of this is due to more competitive pricing, but it’s also because more and more shops are seeing the light on bridge-style machines.”

Get Help Choosing the Right Machine Tool for Your Needs

For over 30 years, Absolute Machine Tools has provided advanced metalworking solutions and comprehensive services for production machining, mold/die machining, high-speed machining, conventional turning, Swiss turning, wire EDM, die sinkers, hole poppers, and deep hole drilling/finishing. We help machine shops and manufacturing facilities improve their production processes to be more competitive. Contact us today to learn more.