After World War I, the only method used to make a hole in a gun barrel or tube was to deep hole drill it using a gun drilling machine. Since then, barrel manufacturers have developed other methods for drilling holes for specific applications efficiently, and pull reaming is one of them. However, each hole drilling process had to be developed and perfected for various applications. Barrel and tube manufacturers could not efficiently build a machine for each specific use. This would have been far too expensive to achieve and take too much time. That is when companies such as Precihole Machine Tools began to design and develop machine tools that specialize in the pull reaming process.

Precihole Machine Tools has spent the last 40 years perfecting the art of drilling and finishing holes in barrels for the firearms and defense industries, tubes and cylinders for the energy and heavy equipment industries, and medical components used in the medical industry for items such as bone screws and rods for internal human use. Nearly 15 years ago, the company partnered with Absolute Machine Tools to represent them in the North American manufacturing market.

Understanding Pull Reaming’s Contribution to the Firearms Industry

Pull reaming gun barrels refers to a machining process used in the industries mentioned above. Reaming is a precision machining operation that involves enlarging and smoothing the internal surface of a gun barrel or large tube to improve the bore’s dimensions, finish, and alignment. The process is accomplished by “pulling” a “reaming” tool through the barrel or tube to achieve the desired results.

Pull reaming helps ensure that the bore has the correct diameter, is straight, and has a smooth ID surface finish. All 3 results are crucial for the proper functioning and accuracy of the products being manufactured. The technique of pull reaming is used by gunsmiths and barrel manufacturers, and is an essential step in the production of high-quality, precise, and reliable firearms.

The Process of Pull Reaming from Start to Finish

Pull Reaming is a precision machining method and may vary slightly depending on the specific firearm, reaming tool design, and equipment used in the process of manufacturing. Manufacturers, such as Precihole Machine Tools in cooperation with Absolute Machine Tools, follow the steps below to ensure that the production of barrels meet the necessary standards for accuracy and performance as set by the industry they are serving:

Absolute Machine Tools and Precihole: Your Deep Hole Drilling and Finishing Partner

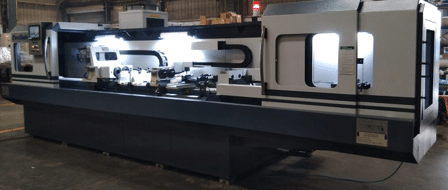

Precihole Machine Tools stands at the forefront of delivering high-precision technology for deep hole drilling and finishing. With a partnership spanning over a decade, Absolute Machine Tools has been a proud collaborator with Precihole in their specialized offerings for the defense and firearms sectors. Precihole’s dedication to this specialized area has garnered international acclaim for their innovative approaches and a steadfast commitment to client satisfaction. Their distinctive edge comes from their custom engineering solutions, tailored to meet specific project needs, thereby ensuring project success.

The field of deep hole drilling technology has been a game-changer in precision engineering across various industries. Its unmatched accuracy, surface finish, and hole integrity are crucial in manufacturing intricate parts for essential applications. At Absolute Machine Tools, our extensive knowledge and cutting-edge solutions make us your go-to partner for all deep hole drilling and finishing requirements. Contact us today to discover our full product range and experience our exceptional customer support.