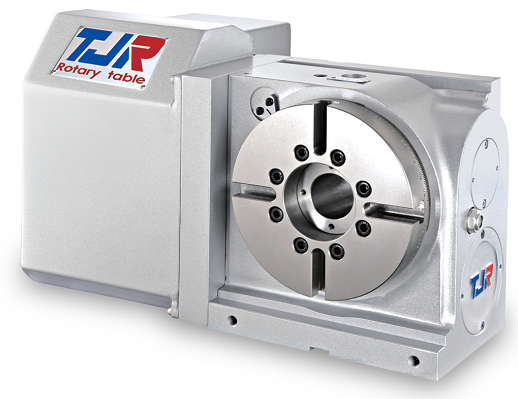

TJR AR Series Left Side

The AR-Series is TJR’s standard 4th axis rotary table. The models featured here are for Left side motor mounting and range from 125mm (4.92”) to 250mm (9.84”) face plate diameter.

They are capable of being used as a full 4th axis that is integrated into the CNC machine control or as an indexer with the use of TJR’s SAC (Single Axis Controller). These units are capable of being mounted in both the vertical and horizontal position. In addition, they are also offered Right Handed and Rear (Back) motor configuration with a powerful pneumatic braking system.

The AR series is manufactured with a radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting. The AR-Series uses a dual lead worm shaft and worm gear to ensure long term indexing accuracy in both directions.

Specifications

| Item / Model |

Unit

|

AR-125L

Request a Quote |

AR-170L

Request a Quote |

AR-210L

Request a Quote |

AR-250L

Request a Quote |

|---|---|---|---|---|---|

|

Table Diameter |

mm |

Ø 125 |

Ø 170 |

Ø 210 |

Ø255 |

|

Diameter of Table Central Hole |

mm |

Ø 35H7 |

Ø 67 |

Ø 67 |

Ø 67 |

|

Inner Diameter of Mandrel Sleeve |

mm |

– |

Ø 40H7 |

Ø 40H7 |

Ø80H7 |

|

Diameter of Center Through Hole |

mm |

Ø 25 |

Ø 40 |

Ø 40 |

Ø 40 |

|

Center Height (Vertical) |

mm |

110 |

135 |

160 |

160 |

|

Table Height (Horizontal) |

mm |

152 |

152 |

152 |

160 |

|

Table T-slot Width |

mm |

12H7 |

12H7 |

12H7 |

12H7 |

|

Guide Block Width |

mm |

14h7 |

18h7 |

18h7 |

18h7 |

|

Min. Increment |

deg. |

0.001 |

0.001 |

0.001 |

0.001 |

|

Indexing Precision |

sec. |

40 |

20 |

20 |

20 |

|

Repeatability |

sec. |

4 |

4 |

4 |

4 |

|

Clamping System (Pneumatic) |

kg/cm2 |

6 |

6 |

6 |

6 |

|

Clamping Torque |

kg-m |

13 |

31 |

31 |

31 |

|

Servo Motor Model (FANUC) |

Taper shaft |

α2i / ß4is |

α4i / α8i / ß8is |

α4i / α8i / ß8is |

α4i / α8i / β8is |

|

Servo Motor Model (MITSUBISHI) |

Taper shaft |

HF-75 / 105 |

HF-54 / 104 |

HF-54 / 104 |

HF-104 / 154 |

|

Speed Reduction Ratio |

– |

1:60 |

1:90 |

1:90 |

1:90 |

|

Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

83.3 |

44.4 |

44.4 |

44.4 |

|

Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

2 |

5.4 |

8.3 |

11.7 |

|

Allowable Workpiece Load (Vertical) |

kg |

50 |

75 |

75 |

75 |

|

Allowable Workpiece Load (with Tailstock) |

kg |

100 |

150 |

150 |

150 |

|

Allowable Workpiece Load (Horizontal) |

kg |

100 |

150 |

150 |

150 |

|

Allowable Load with Rotary Table Clamping (F) |

kgf |

1000 |

1450 |

1450 |

1450 |

|

Allowable Load with Rotary Table Clamping (FxL) |

kgf.m |

45 |

100 |

100 |

100 |

|

Allowable Load with Rotary Table Clamping (FxL) |

kgf.m |

13 |

31 |

31 |

31 |

|

Strength of worm gears (Rotary axis) |

kg.m |

9 |

18 |

18 |

18 |

|

Net Weight (servo motor excluded) |

kg |

34 |

50 |

55 |

58 |