How OB7’s Smart CNC Integration Elevates Production

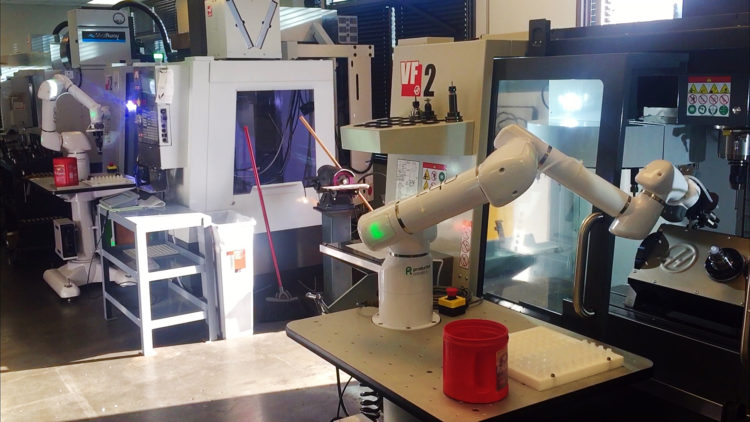

The manufacturing landscape is on the cusp of a new dawn, where the synergy between man and machine isn’t just a sci-fi premise — it’s a daily reality. The OB7 collaborative robot from Productive Robotics is at the forefront of this revolution, redefining the integration of automation in CNC operations. It’s not just a robotic arm; it’s a productivity powerhouse, a beacon of efficiency in the modern workshop. Here are 8 reasons why:

1. Running Lights Out Is a Manufacturing Game Changer

Picture a production line that never sleeps — where the hum of productivity is ceaseless, and the rhythm of production is uninterrupted. OB7 brings this vision to life with its ‘lights out’ production capability. By ensuring that spindles keep turning, OB7 allows manufacturers to enjoy the fruits of 24/7 operation. Downtime becomes a relic of the past, as does the worry of breaks, absences, or production stoppages.

2. A Swift Journey to Return on Investment

The promise of a fast ROI in the realm of industrial automation has often been elusive—until now. OB7 changes the narrative with its rapid deployment and ease of operation. Setting up the OB7 doesn’t require weeks of complex programming and integration. In fact, it’s a matter of hours before it’s up and running, starting its journey of boosting your bottom line. With financing options designed to accelerate ROI, OB7 isn’t just an investment — it’s a catalyst for growth.

3. “No-Programming” Operation: Simplicity Meets Sophistication

In an industry where programming complexity can be a significant barrier, OB7 stands apart with its “no-programming” operation. The intuitive, tablet-like interface takes the complexity out of the equation. Operators can ‘teach’ OB7 the required tasks with simple movements, a feature that not only saves time but also democratizes the use of advanced robotics across all skill levels.

4. Unmatched Flexibility with 7-Axis Movement

Where traditional cobots end, OB7 begins. With its seventh axis, OB7 boasts maneuverability that’s unmatched in the cobot space. This additional axis allows it to reach around obstacles and into tight spaces with human-like dexterity, offering unparalleled reach and flexibility.

5. Scalability and Versatility: OB7 Adapts to Your Needs

Whether you’re switching between multiple short runs or diving into mass production, OB7 adapts to the task at hand. Its compact design does not compromise on capability, handling payloads up to 12 kg and reaching up to 1700 mm. This adaptability makes OB7 an ideal partner for any production volume or mix.

6. Seamless CNC Integration

Integration with existing CNC setups is a breeze with OB7. It’s compatible with a vast range of machine types and OEMs, allowing for a swift and straightforward “plug and play” setup. Rolling OB7 into place and teaching it a job can be done in moments, offering instant CNC automation without the headaches.

7. Collaborative Safety: A Core Philosophy

Safety in automation is paramount, and OB7 is designed with this in mind. It works alongside your employees without the need for safety fences or cages, fully compliant with ISO 10218-1 standards. This collaboration ensures that OB7 is not just another member of the team but a safe, interactive coworker.

8. Embracing All Production Sizes

OB7 shines in any production scenario. Its intuitive integration and versatile performance mean it’s as comfortable with low-volume, high-mix applications as it is with high-volume production runs. Automation with OB7 is as efficient for ten pieces as it is for ten thousand.

Client Success with OB7: Swiss Productions’ Story

Swiss Productions, a Ventura, California-based precision machine shop, faced a bottleneck in maximizing spindle time. Their search for efficiency led them to the OB7 cobot, known for its 7-axis dexterity. General Manager Timo Lunceford noted the immediate fit:

“When we discovered OB7, we knew the 7th axis for us is key. We are going in, grabbing the parts, moving sideways with them, and then blowing out the collets that we are using to hold our parts. We need a quick turn radius because we also have to teach it to close the door and then double check that the door is closed, and then be able to pivot to press the start button, which is a complete 180° from where it was,” Lunceford said.

The OB7 integration was quick and transformative, significantly increasing machine running time without the need for additional staffing.

“The employee that would normally sit at the machine before OB7 is now able to run two of our smaller lathes at the same time. Previously, the cycle time wouldn’t allow for that between all three machines,” Lunceford said.

The impact of OB7 on Swiss Productions has been profound. With two OB7 units now in operation, they continue to explore new avenues for improvement and expansion.

The Next Step in CNC Automation Awaits

Are you ready to witness how OB7 can transform your CNC operations? Contact us to schedule a demonstration and step into the future of collaborative robotics. Let OB7 take the wheel of your production line, driving efficiency, and innovation, paving the way for a smarter manufacturing world.

For more on how OB7 can streamline your production, reach out to Absolute Machine Tools at info@absolutemachine.com.