Experiencing Chip Challenges?

LAST MODIFIED ON: August 22, 2024

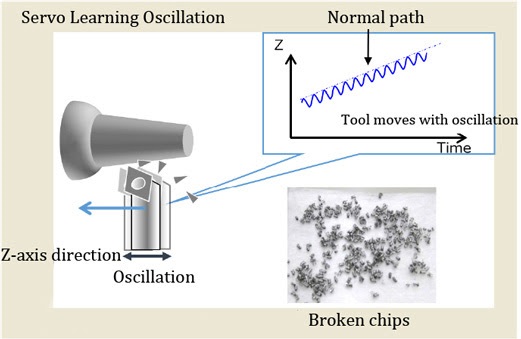

Servo Learning Oscillation Is the Ultimate Chip Control Technology

The main purpose of Servo Learning Oscillation is to eliminate long, stringy chips from gathering around the part and cutting tool during the machining process. By constantly changing frequencies through the X, Y, and Z axes combined with interrupting cutting on the part, the chips will break away clean allowing for continual flawless cutting.

Swiss machines have a small work area, which can make chip ejection a common problem. Chips tend to get entangled around the part or the tool, which can increase cutting resistance, increase cutting heat (causing built-up edges), cause surface damage and scarring, damage the cutting tool, and clog the tool flutes, all of which are undesirable effects.

Applying this feature during the cutting process is how the phrase “Breaking the Chip” was born. The Servo Learning Oscillation feature on Nexturn Swiss CNC lathes is best used on any hard-to-machine materials including aluminum or stainless steel.

Benefits of the Servo Learning Oscillation Feature

- Increased productivity because it prevents chip problems such as hanging chips and birds’ nests, so your machines can operate continuously with no operator intervention ultimately leading to reduced production time overall

- Ideal solution for problems such as chip entanglement and built-up edges in hard-to-cut materials like Inconel, surgical stainless and copper

- No additional hardware needed (just software)

- Accuracy of the part is not compromised

- Stable part quality

- Improved tool life and reduced equipment costs

Email info@absolutemachine.com or call us at (800) 852-7825 to learn more!