OB7 Cobot Software Update Adds 50 Operational and Ease-of-Use Features

A new OB7 cobot software update added 50 operational and ease-of-use features to the Productive Robotics line of collaborative robots. The software updates enhance the cobots’ connectivity, expedite efficient integration with other equipment, and facilitate real-time status monitoring.

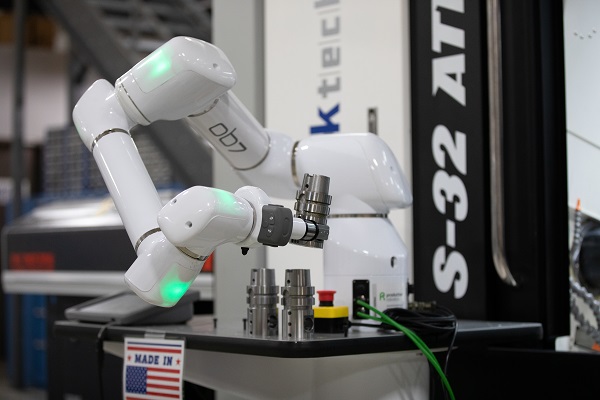

The family of four different OB7 collaborative robots all have 7 axes, which allows for extended flexibility and enables them to reach around obstructions and operate in confined workplaces. OB7 is engineered to accomplish simple to complex tasks for various payloads and sizes.

The list of new and upgraded features includes full linear control that broadens the cobots’ “no-programming, no coding,” simple-to-teach intelligence.

The OB7 software updates also improved the OB7s’ ability to directly monitor and control the machines they work with by:

“Productive Robotics is an innovative leader in the development of next-generation collaborative robotics technology,” said Courtney Ortner, chief marketing officer at Absolute Machine Tools. “With this new software launch, Productive Robotics reinforces that the OB7s are the smartest, simplest to use, and easiest to deploy 7-axis cobots on the market.”

OB7 Sales & Support

Productive Robotics, together with Absolute Machine Tools, is committed to providing comprehensive engineering assistance for custom-tailored automation, robotics and turnkey machining solutions aimed at reducing manufacturing costs. Because they are manufactured in the U.S., Productive Robotics cobots benefit from fast, reliable technical support and part supply services.

Call Absolute Machine Tools at 800-852-7825 or email us at info@absolutemachine.com today to learn how a Collaborative Robot can add new automation possibilities to your existing production lines or machines. We are here to provide A+ sales, service and support!