What to Consider When Buying a Precision CNC Machine

In 2019, job shops are expected to spend around $7.750 billion, much of it on trying to improve production efficiency. This means buying new precision CNC machines or upgrading old equipment.

If you’re among those job shops looking for a new machine tool this year, Absolute Machine Tools has the production turning solutions you’re looking for. However, there are many things to consider before buying new equipment.

Before You Buy, Ask Yourself “Why?

This seems like an obvious step, but it’s one that can’t be ignored. Investing in a new precision machine tool is a large financial undertaking, but one that can pay for itself over and over if you choose the right equipment.

Before you consider a particular purchase, ask yourself why you need a new machine. Will it help streamline your current production? Will it allow you to secure new contracts or pursue new types of jobs? Will it improve your job shop’s production efficiency or quality?

Find the Right Machine for the Job

How this new equipment will be used — that will guide you in choosing the right type of precision CNC machine tool and lead you to the specific model for your needs.

Consider questions like:

The last question is perhaps the most important one, as the geometry of the parts you are machining will dictate the type of holding device or fixtures you’ll need, whether you’ll need a 4th or 5th axis, the size and number of cutting tools you’ll need, and more.

Get 2nd Opinions

Deciding to buy a machine that costs more than most houses is not a decision that should be made quickly and without comprehensive thought. Seek input from the different departments that will be involved in and responsible for the operation and upkeep of the machine. Talk to engineers, maintenance, production and any other applicable departments to get their thoughts, ideas and questions.

The larger the company, the more departments you’ll likely be seeking input from, but even in a small operation it’s can be important to consider input from any other personnel directly involved in the machine’s operation.

Talk to the Experts at Absolute Machine Tools

When you’re trying to choose the right precision CNC machine for your job shop, talk to the sales and applications engineers at Absolute Machine Tools. Our No. 1 goal is to find innovative cost-effective engineered solutions to your manufacturing challenges. And while many OEMs have lead times of 12 months or more on new equipment, Absolute has over 100 machines in stock for immediate delivery.

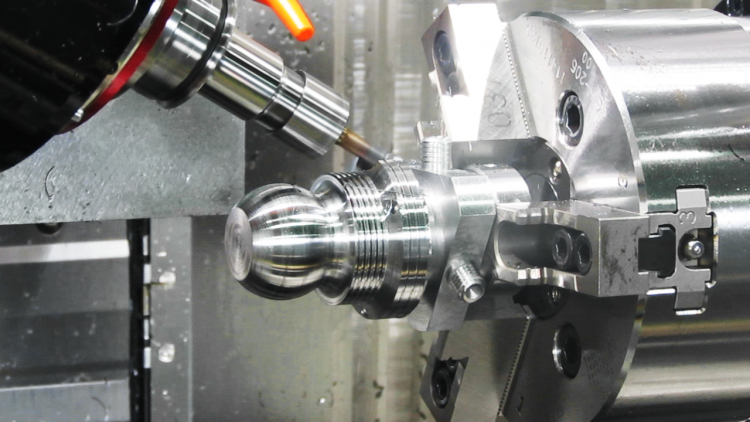

We offer 3 versatile precision CNC machine tool lines specifically engineered towards the production turning industry: Nexturn Swiss-style lathes, LICO single-spindle multi-slide CNC screw machines and QuickTECH twin-spindle multi-axis CNC mill/turn centers.

Contact us today at sales@absolutemachine.com to learn more!