Mold/Die Machining

CNC Machines for Mold and Die Shops

Ready to Transform or Update Your Mold Shop?

With more mold and die work returning to North America, you need reliable equipment that delivers tight tolerances, mirror finishes, and repeatable precision. For decades, Absolute Machine Tools has provided CNC solutions that help moldmakers achieve net-shaped parts, reduce lead times, and boost profitability.

Proven CNC Solutions for Moldmakers

Our machines aren’t new to mold shops — they’ve earned their reputation for quality, longevity, and performance in North America’s moldmaking industry. From roughing large bases to burning complex cavities, we have your shop covered.

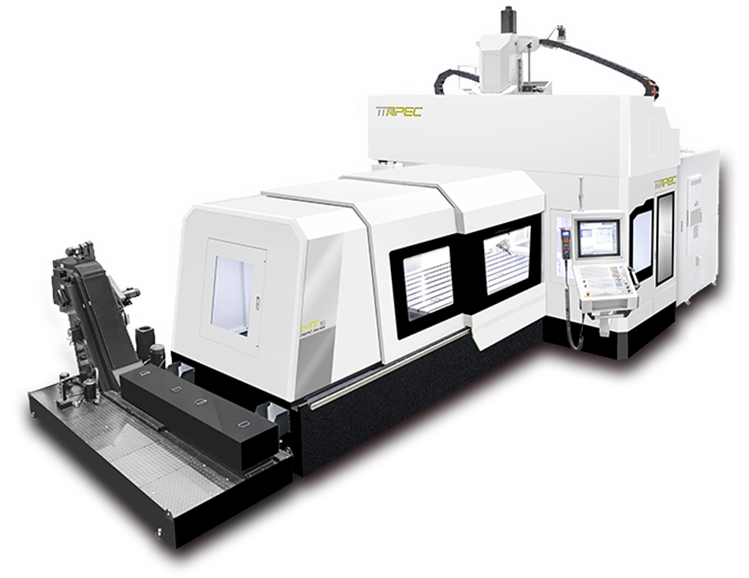

5-Axis High-Speed Gantry Machining Centers

3-Axis Knee-Type Gun Drilling Machines

Die Sinker EDM Machines

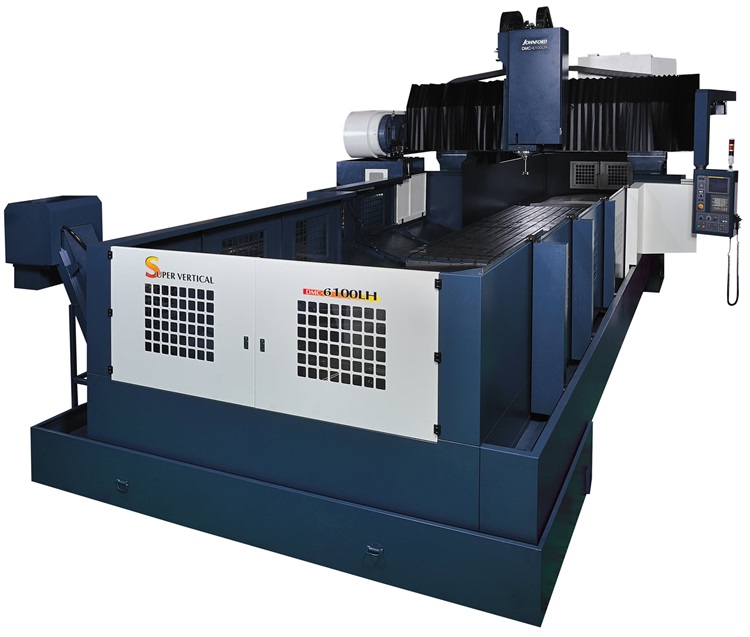

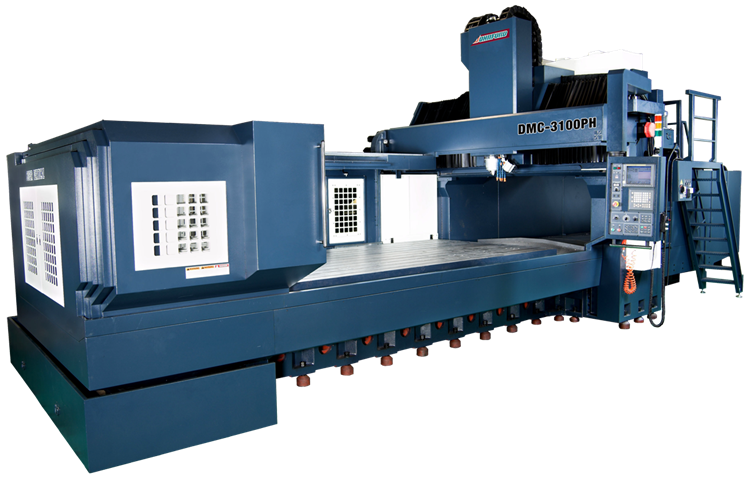

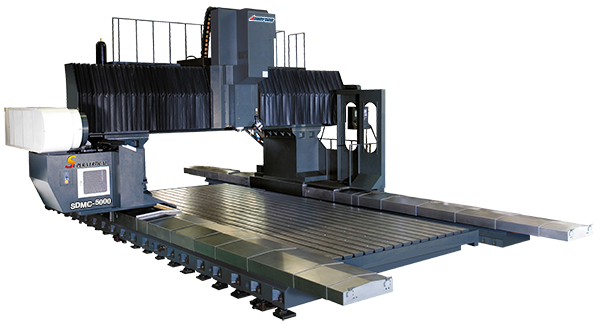

Bridge Mills

Wire EDM Machines

Machines

5-Axis Large Format High Speed Gantry Machining Centers for Aerospace & Injection Molds

Johnford Massive Fixed or Moving Table/Fixed Column Bridge Mills

5-Sided/5-Axis Options for Specific Johnford DMC Models

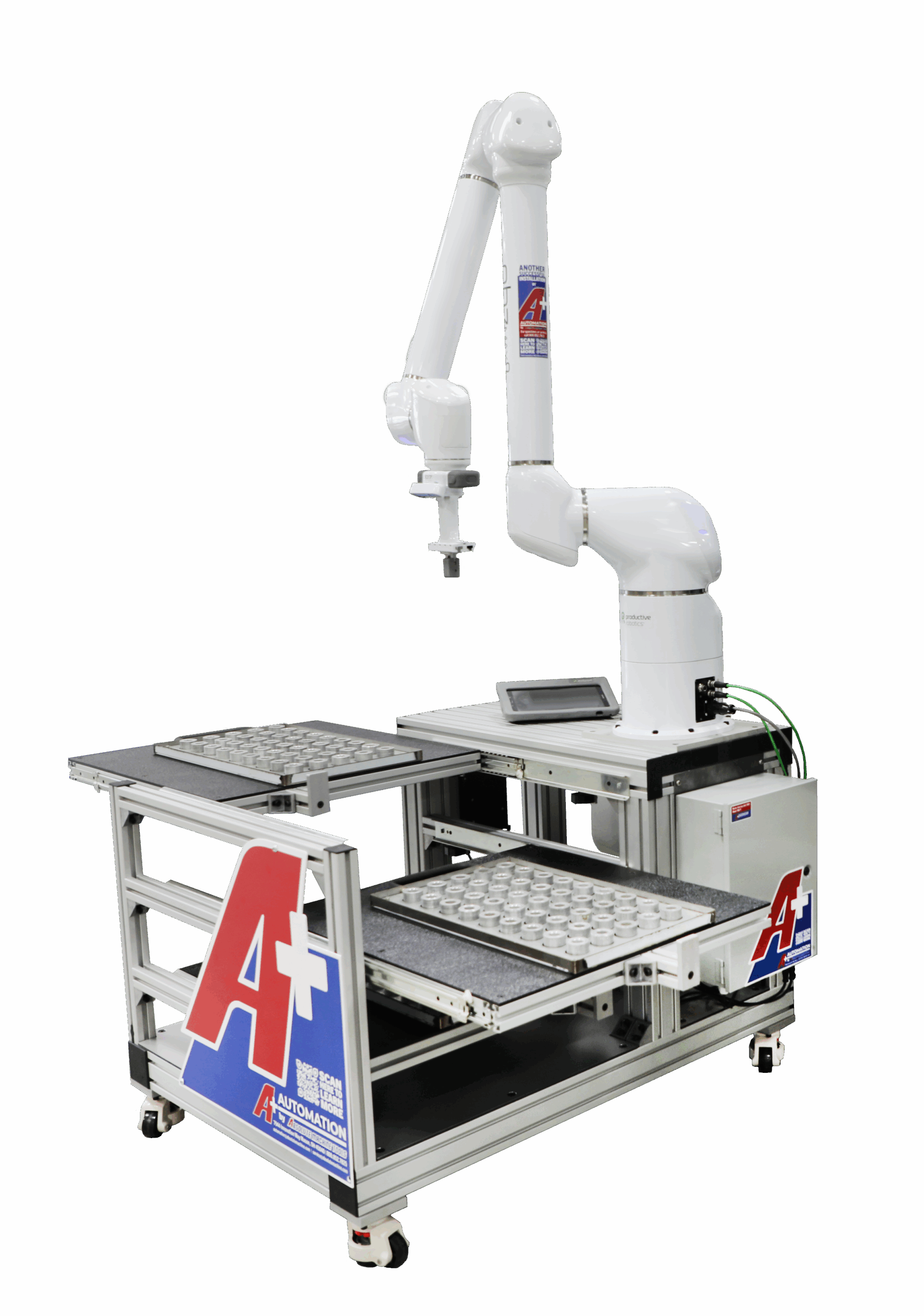

Pallet changers, quick-change systems, robotic part loading and unloading, automatic electrode changers

Automation-Ready for Lights-Out Production

Our A+ Automation Team specializes in affordable, scalable solutions to help mold shops run lights-out:

Working together with our applications engineering team, we’ll design and implement a system that reduces labor costs, improves safety, increases uptime, and supports around-the-clock production.

Deep Moldmaking Expertise You Can Rely On

Absolute Machine Tools has nearly 40 years of experience serving the mold and die industry — from the days when moldmaking was a dominant force in North America to today’s era of reshoring and rebuilding. We understand what it takes to help shops modernize, stay competitive, and succeed in a revitalized U.S. manufacturing landscape. We help shops make the most of modern tooling, workholding, CAD/CAM, and CNC controls to machine complex cavities, core blocks, plates, inserts, cooling channels, and waterlines with precision and efficiency.

Ready to Learn More?

Contact Absolute Machine Tools today to talk with our team about the right CNC solutions for your mold shop. Let’s build something better together.

What CNC machines are best for mold shops?

High-rigidity bridge mills, die sinker EDMs, and wire EDMs deliver the precision and repeatability moldmakers need.

Can CNC moldmaking be automated?

Yes! Absolute Machine Tools offers pallet changers, robots, and electrode changers for lights-out production.

What industries use mold and die CNC machines?

Automotive, aerospace, medical, packaging, and consumer goods all rely on precision moldmaking.

OEMS

Johnford CNC Machines

Take your mold and die manufacturing to the next level with the Johnford CNC machines, crafted with state-of-the-art technology for unmatched precision and efficiency. Designed for both complex molds and detailed dies, these machines stand out for their accuracy, ensuring top-notch results. Their sturdy build and premium components make them ideal for the rigorous demands of mold and die manufacturing, offering both durability and minimal downtime for enhanced productivity.

Seiki Mill/Drill/Tap Centers

Experience the excellence of Seiki Mill/Drill/Tap Centers, synonymous with precision and adaptability. These machines are adept at handling diverse operations like milling, drilling, and tapping, with a focus on precision for intricate mold and die projects. Seiki machines are built for consistent performance, setting the standard in manufacturing precision.

Precision Deep Hole Drilling Machines

Reinvent drilling with Precihole’s specialized Deep Hole Drilling Machines, ideal for both large and small mold and die applications. These machines excel in crafting angular holes in various parts, combining customization and versatility to streamline operations and enhance productivity.