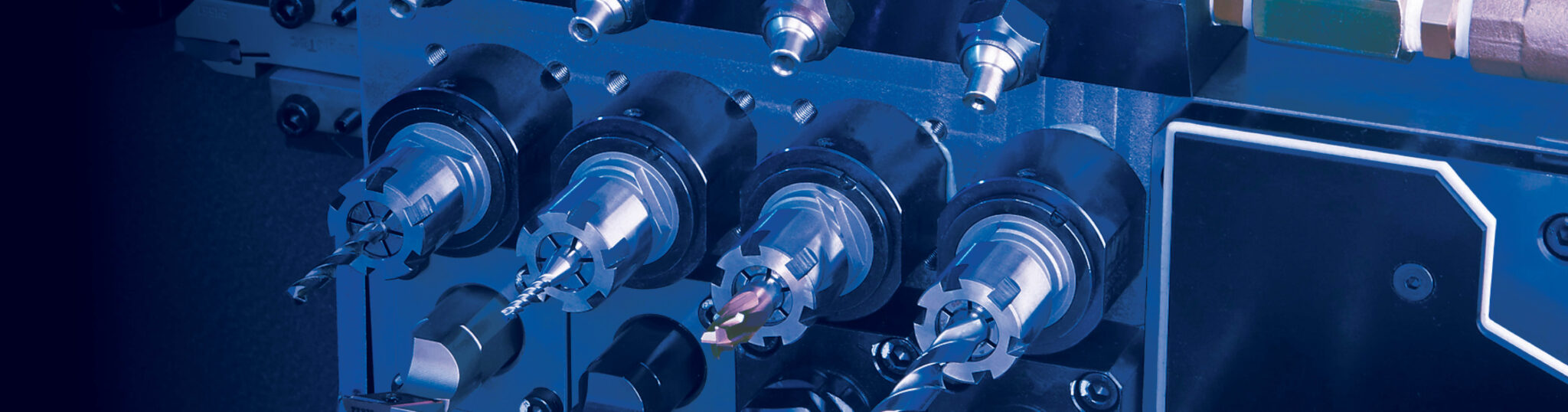

Swiss Lathes

Absolute Machine Tools is proud to offer Nexturn Swiss-style CNC lathes, which engineered to maximize accuracy and profitability in the production machining of complex precision parts. Nexturn Swiss-style machines include basic guide-bushing-equipped machines with maximum bar capacities from 12mm to 38mm diameter, exchangeable guide-bushing machines from 20mm to 38mm capacity, and non-guide-bushing machines with 26mm to 51mm bar capacity. In addition, Nexturn provides turret type non-guide-bushing, sliding-headstock machines to process 45 mm, 56mm, and 67mm diameter bars.

Six different CNC Swiss lathe series are designed to meet specific production and economic requirements. Most models feature different levels of sophistication and options that enable Swiss CNC machine capabilities to be tailored to fit any budget.

|

7-Axis Industry Leading Efficient Model with 22 Tools

|

|

|

7-Axis Performance Model, Exchangeable Guide Bushing & Modular Rotary Spindles

|

|

|

8-Axis Performance Model, Dual Y, 27 Tools, Exchangeable Guide Bushing & Modular Rotary Spindles

|

|

|

9-Axis Advanced Model with Fully Programmable B-Axis, 33 Tool Capacity, Exchangeable Guide Bushing & Modular Rotary Spindles

|

|

|

11-Axis Advanced Model with 3-Channel Dual Opposed Gang Tool Post, 33 Tools, Exchangeable Guide Bushing & Modular Rotary Spindles

|

Nexturn Swiss Lathes Are Available with the Servo Learning Oscillation Option!

The Servo Learning Oscillation feature from Fanuc is available to prevent chip challenges manufacturers may experience when working with hard-to-machine materials. If you’ve had issues with long, stringy chips creating a bird’s next around your part during the cycle, this option is the solution! This feature breaks the chip by constantly changing frequencies through the X, Y, and Z axes.

Learn More About Servo Learning OscillationMachines

What Materials Can Be Machined on a Swiss CNC lathe?

- Steel – commonly used in the automotive, aerospace, and construction industries.

- Stainless Steel – often used in medical and dental equipment, food processing, and aerospace industries.

- Aluminum – used in the automotive, aerospace, and construction industries for its lightweight and corrosion-resistant properties.

- Titanium – used in aerospace, medical, and military industries due to its strength-to-weight ratio and biocompatibility.

- Brass – often used in the plumbing, electrical, and musical instrument industries.

- Copper – commonly used in electrical and plumbing applications.

- Bronze – often used in bearings, bushings, and marine applications.

- Inconel – used in aerospace, nuclear, and chemical industries due to its high temperature and corrosion resistance properties.

- Hastelloy – used in the chemical processing and nuclear industries for its high-temperature and corrosion-resistant properties.

- Monel – often used in marine and oil and gas industries due to its corrosion-resistant properties.

The specific metal that can be machined on a Swiss CNC lathe may depend on the machine’s capabilities, tooling, and cutting fluids used. Contact Absolute to learn more!

Would Purchasing a Swiss CNC Lathe Benefit My Machine Shop?

Determining whether a Swiss CNC lathe will benefit your manufacturing facility depends on several factors, including the types of parts you produce, the volume of production, the level of precision and accuracy required, and the available resources and budget.

Here are some key factors to consider when evaluating the potential benefits of a Swiss CNC lathe for your facility:

- Part complexity: If your facility produces small, complex parts with tight tolerances, a Swiss CNC lathe can be a highly effective solution. These machines are designed to handle complex geometries and produce parts with high precision and accuracy.

- Volume of production: Swiss CNC lathes are ideal for high-volume production of small parts. If your facility produces a high volume of parts, a Swiss CNC lathe can significantly increase efficiency and reduce lead times.

- Quality control: Swiss CNC lathes are equipped with advanced monitoring and control systems that ensure high-quality production. If your facility requires consistent quality control, a Swiss CNC lathe can provide the necessary level of precision and accuracy.

- Labor costs: Swiss CNC lathes are highly automated, which can reduce the need for manual labor and increase efficiency. If labor costs are a concern, a Swiss CNC lathe can be a cost-effective solution.

Ultimately, the decision to invest in a Swiss CNC lathe should be based on a careful evaluation of your facility’s specific needs and resources. It’s important to work with an experienced supplier or manufacturer to ensure that you choose the right machine for your operation.

Frequently Asked Questions About Swiss Lathes

Swiss type lathes are a specialized type of Swiss CNC lathe. Swiss lathes are designed for machining small, complex parts with a high degree of accuracy. They typically have a diameter capacity of less than 20 mm (0.79 in) and can operate at extremely high speeds, making them well suited for machining high precision parts.

Swiss-type lathe machines generally have a wider variety of tooling options than other types of CNC lathes, which further enhances their versatility. Swiss-type lathes are used in a wide range of industries, including the medical, aerospace, and automotive industries.

Swiss-type lathe machines are designed for making small, precise parts. The Swiss-type lathe is different from a conventional lathe in several ways.

First, Swiss-type lathes have a smaller footprint and require less floor space than a conventional lathe. Second, Swiss CNC lathes have a shorter bed length, which allows for more accurate machining of smaller parts. Third, Swiss-type lathes are equipped with high-pressure coolant systems that enable the machining of difficult-to-cut materials. Finally, Swiss-type lathes are equipped with live tooling, which allows for the machining of complex parts with multiple axes of rotation.

Swiss type lathes offer many advantages over conventional lathes and are an essential tool for any shop that specializes in the machining of small parts.

Swiss machinists are highly skilled workers who operate Swiss turning centers to produce precision parts. Swiss turning centers are computer-controlled lathes that allow for very precise cuts. Swiss machinists must have a strong understanding of engineering and math in order to program the machine and produce parts that meet the required specifications. Typically, they work in manufacturing plants or machine shops.

In some cases, Swiss machinists may also be responsible for training other workers on how to operate Swiss-type lathe machines. Some machinists may also choose to pursue formal education in engineering or a related field. To be successful, they must be able to read and understand technical manuals and blueprints and be able to perform complex mathematical calculations. Swiss machinists must also be able to identify and troubleshoot problems with the CNC Swiss machine or the parts being produced.

Swiss turning is a type of machining that uses a Swiss-type CNC machine. These machines are designed for precision work, and they are often used for small parts that require high levels of accuracy.

Swiss turning works by rotating the workpiece on a spindle, while a cutting tool is fed into the workpiece. The cutting tool is able to move on all three axes, and it can create very complex shapes. The advantage of Swiss turning is its precision and ability to create extremely intricate parts. However, the downside is that it requires a high level of skill to operate.

Swiss CNC lathes are commonly used for producing small parts with complex geometries and tight tolerances, such as medical components, aerospace parts, and electronics. Some examples of applications include:

– Medical components, such as surgical instruments, implants, and prosthetics

– Aerospace parts, such as connectors, fittings, and valves

– Electronics components, such as connectors, pins, and sockets

– Automotive components, such as fuel injectors, valves, and connectors

– Precision watch parts, such as gears, screws, and pins

– Firearms components, such as triggers, barrels, and firing pins

– Hydraulic and pneumatic components, such as fittings and connectors

– Dental components, such as implants, abutments, and brackets

– Optical components, such as lenses, prisms, and mirrors

– Fasteners, such as screws, bolts, and nuts

The setup time for a Swiss CNC lathe can vary depending on the complexity of the part being machined, but generally ranges from several minutes to a few hours.

In general, setting up a Swiss CNC lathe can take several hours to a full day. This includes tasks such as selecting and installing the appropriate tooling, programming the machine for the specific part being machined, and adjusting the machine settings for optimal performance.

However, with advancements in automation and software, the setup time for Swiss CNC lathes has been reduced significantly. Some newer models come equipped with automated tool changers and preset tool libraries, which can greatly reduce the time required to set up the machine. Additionally, some machines have integrated software systems that allow for quicker and more efficient programming.

Ultimately, the setup time for a Swiss CNC lathe will depend on the specific machine and the part being machined. It’s important to work with an experienced operator and to carefully plan the setup process to minimize downtime and ensure optimal performance.

Selecting the right Swiss CNC lathe depends on several factors, including the types of parts you need to produce, the materials you will be machining, and your budget. It’s important to work with a knowledgeable and experienced supplier who can help you choose the right machine for your specific needs. Absolute is here to help! Request a quote today so we can match the right machine to your part.