Precision Production Turning CNC Machines

Integrated CNC solutions for high-precision, high-volume part manufacturing

Production turning is the core of modern mass production, where precision, speed, and efficiency must work together to produce thousands of tight-tolerance parts every shift. The process relies on multi-axis, high precision CNC lathes, mill-turn centers, multi-spindle screw machines, and Swiss lathes — each designed to remove material quickly while maintaining exceptional accuracy and repeatability.

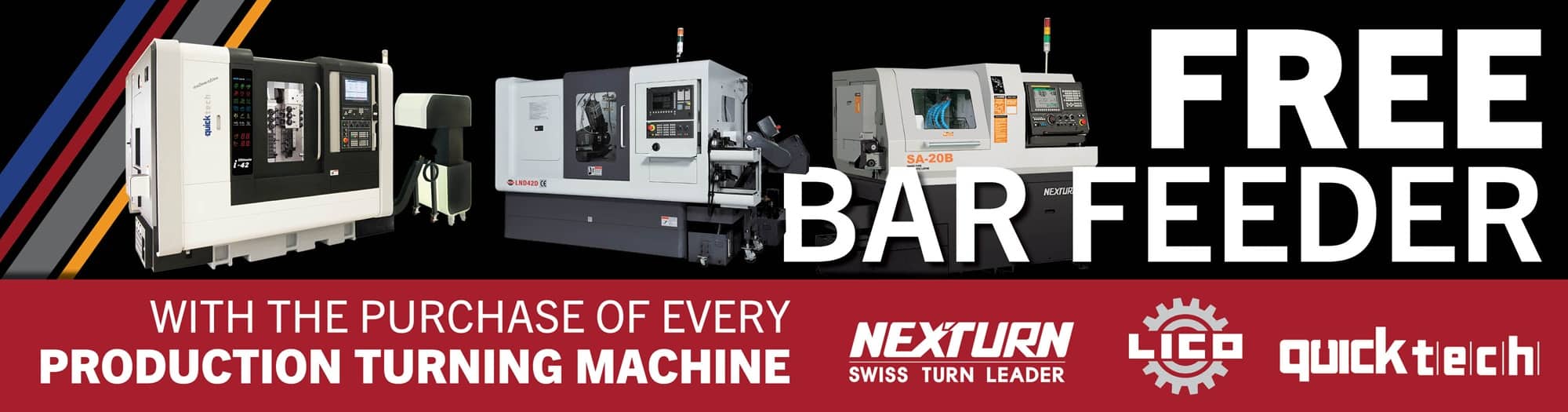

Absolute Machine Tools supports every aspect of this process with a complete range of CNC precision turning solutions. Combined with advanced automation technologies and machine accessories — industrial and collaborative robots, gantry loaders, bar feeders, and bar loaders — these systems deliver continuous throughput, superior part quality, and reliable performance for high-volume manufacturing.

Benefits for Metal Cutting Manufacturers

Production Turning Solutions from Absolute Machine Tools

Absolute Machine Tools represents world-class builders whose technologies define the production turning process:

All are supported by Absolute’s dedicated Production Turning Applications Engineers, who understand the unique demands of this process and work directly with customers to optimize setups, reduce cycle times, and train operators for success.

Proud Technical Member of

the Precision Machine Products Association

Videos

Contact Absolute Machine Tools Today

At Absolute Machine Tools, we deliver more than machines — we deliver complete turnkey production systems from Print to Part. Our experienced service technicians, dedicated Production Turning Applications Engineers, and automation specialists provide full process support to help manufacturers achieve true high-volume efficiency. With a large inventory of machines in stock and ready for immediate delivery, Absolute is your single-source partner for precision production turning success.

Contact our Production Turning team today to discuss your application, schedule a demo, or request a turnkey automation proposal designed to improve your output and profitability.