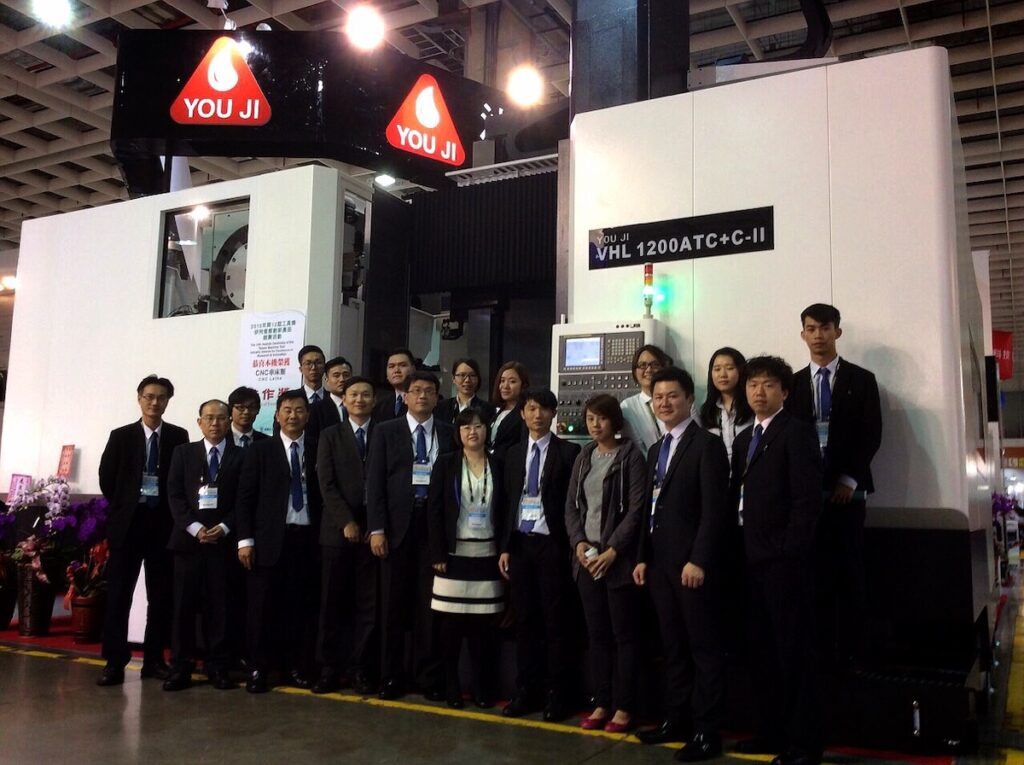

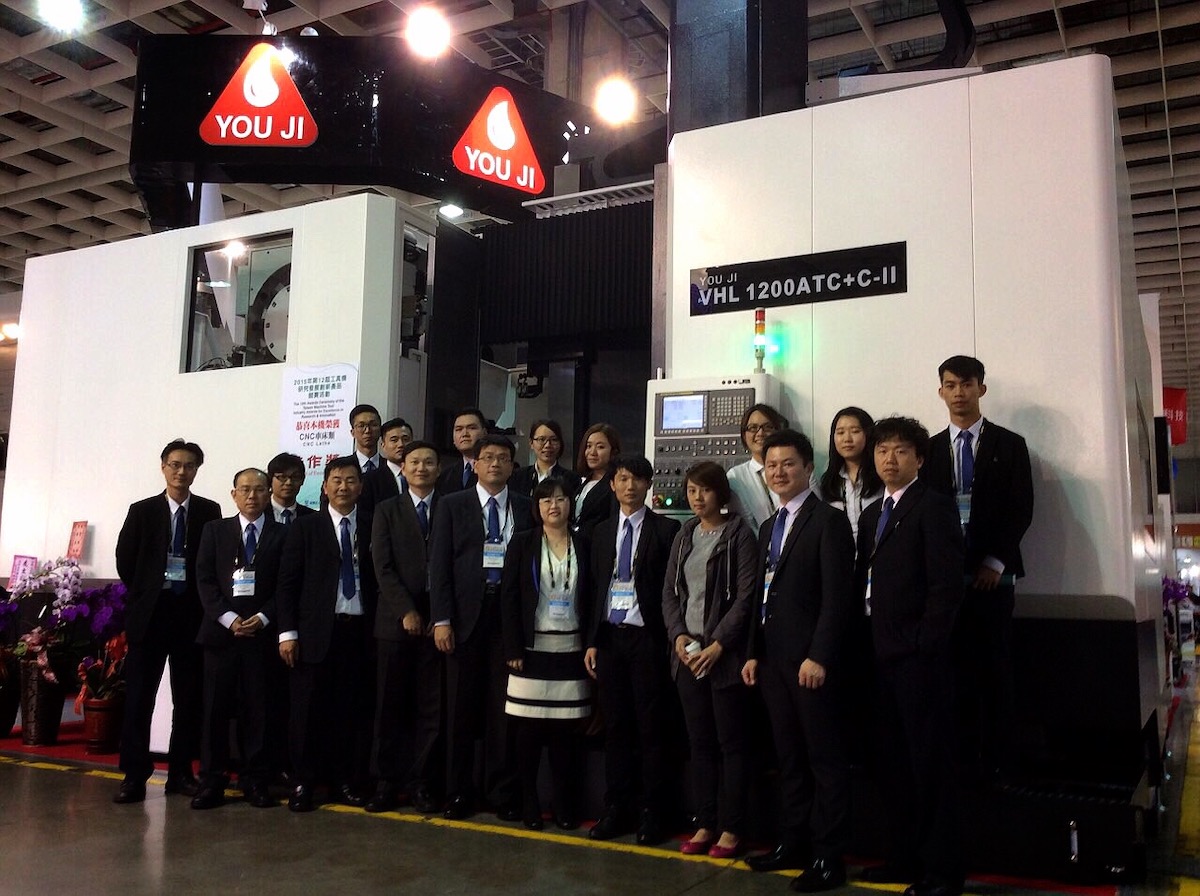

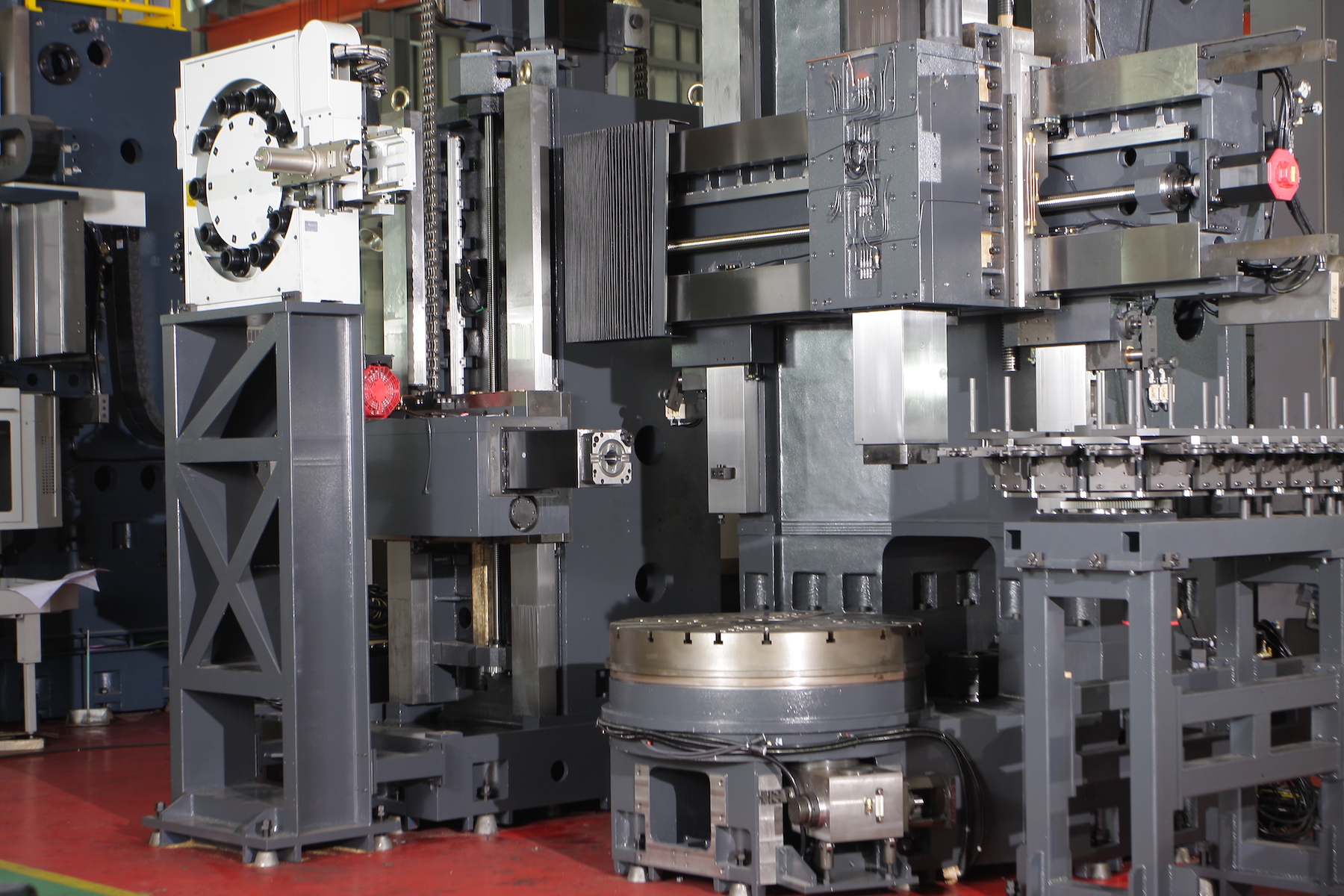

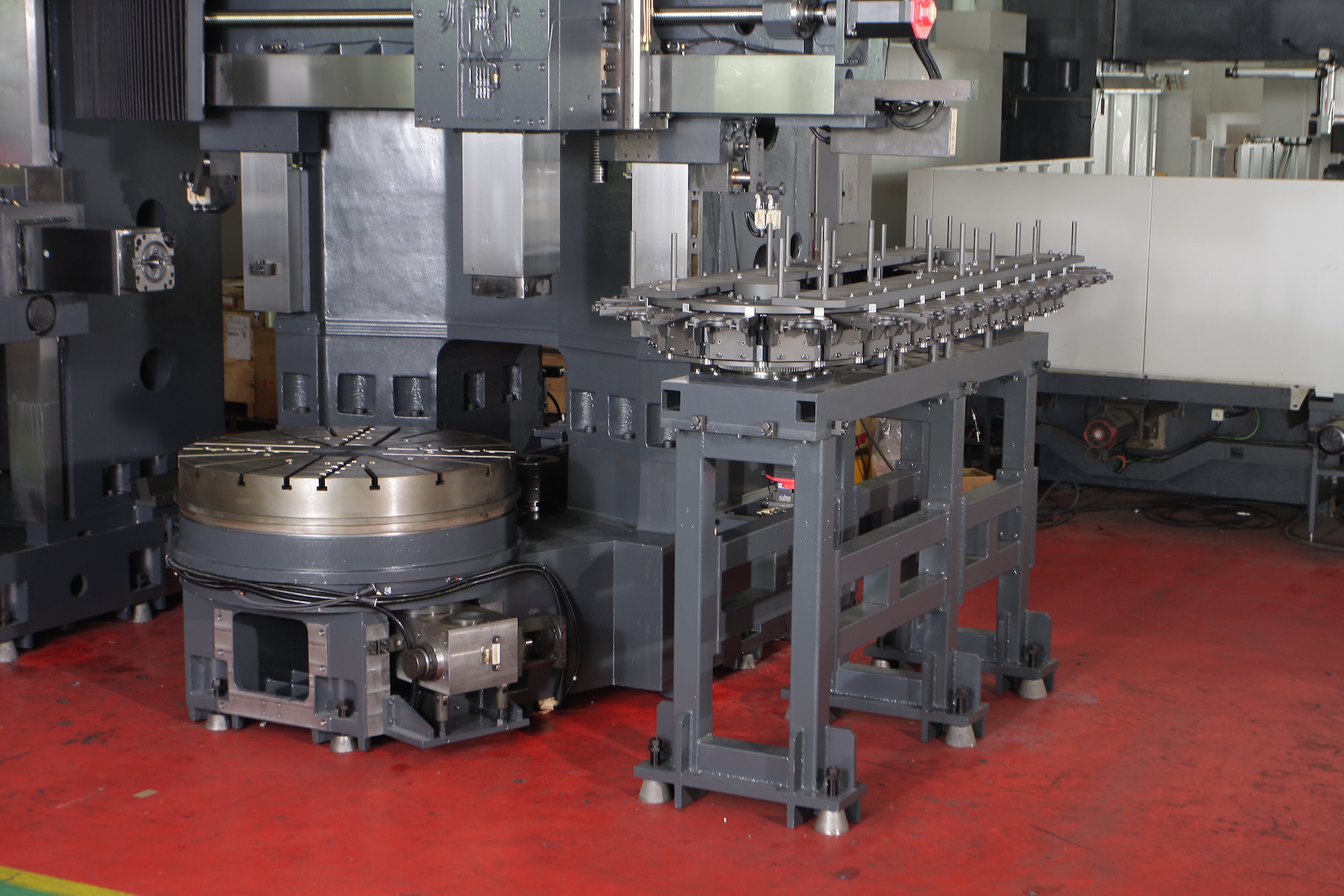

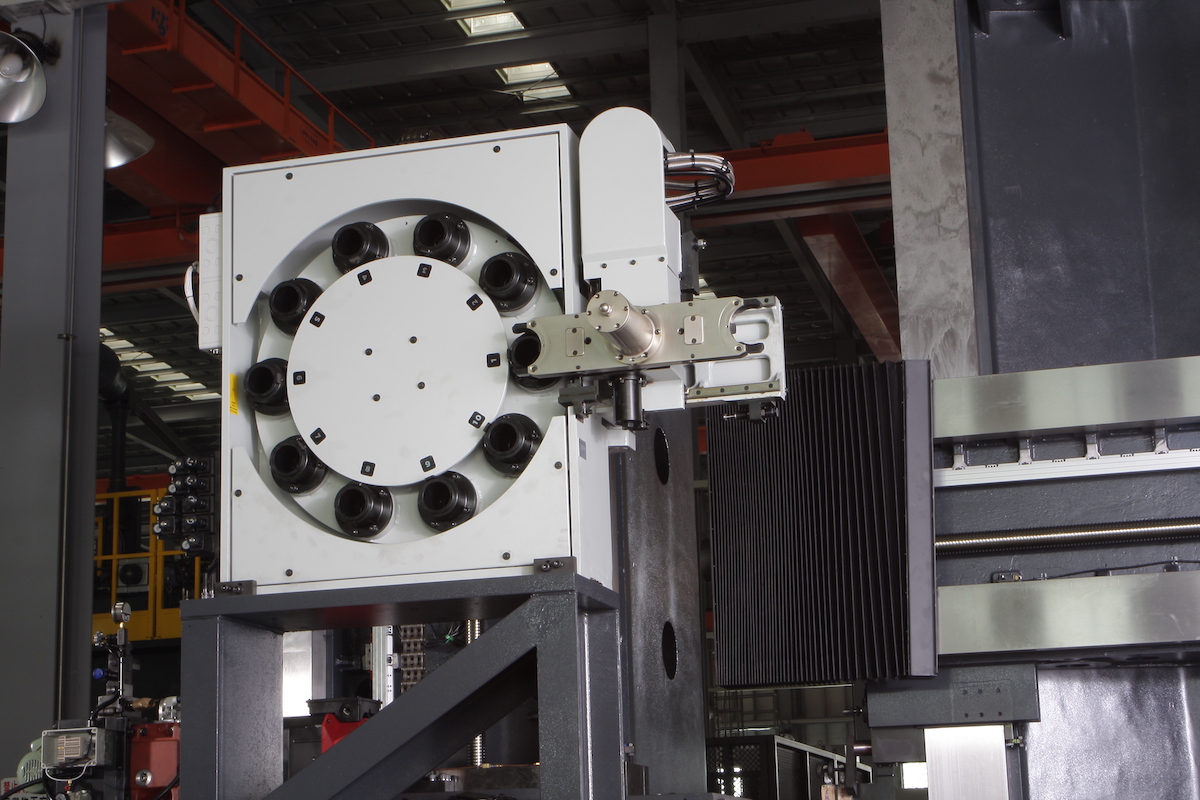

You Ji VHL Series – Vertical Turning Lathes with Side Milling Head

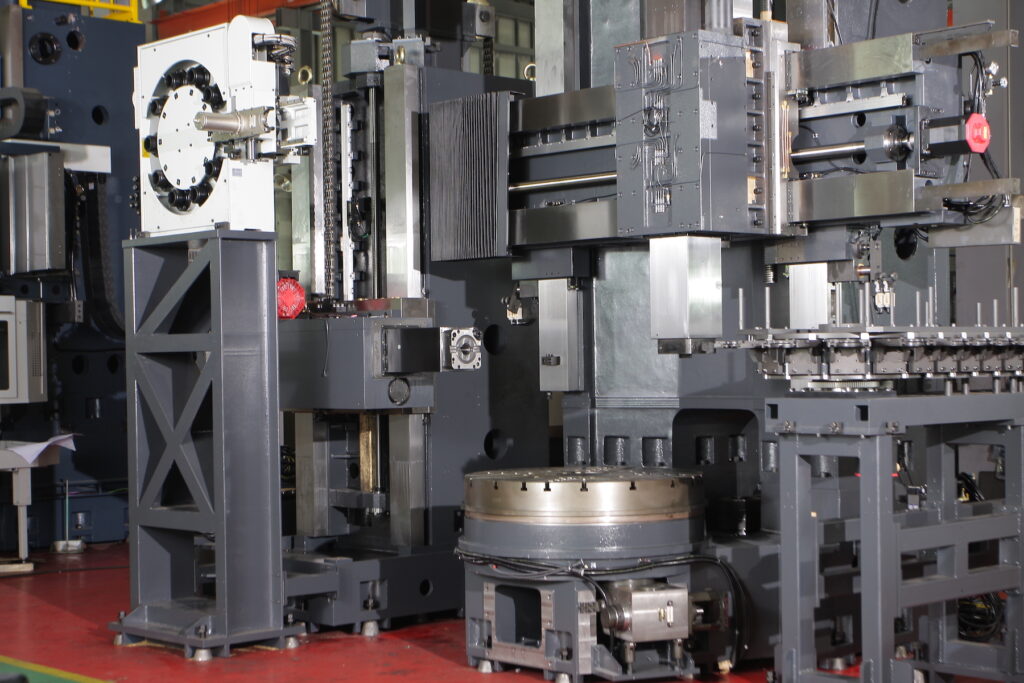

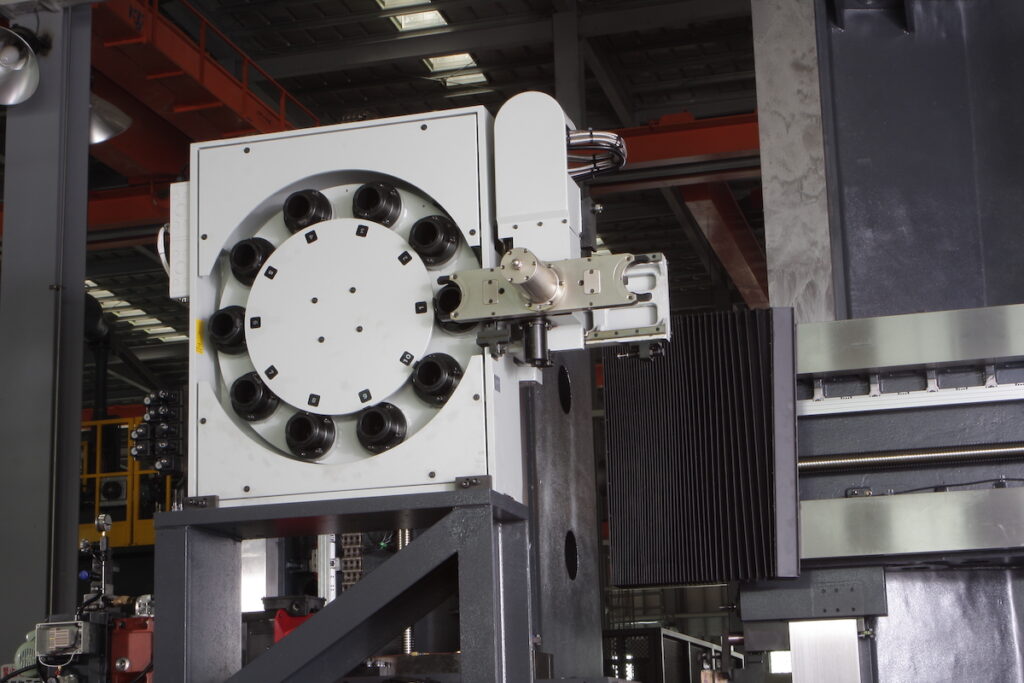

The You Ji VHL Aerospace Components Series comprises advanced vertical turning lathes equipped with side heads, specifically designed for aerospace manufacturing applications. These machines combine a vertical ram with an integrated horizontal side head, facilitating multitasking operations such as turning, drilling, tapping, milling, and grinding.

The horizontal ram extends past wide diameters to access difficult-to-reach areas, enabling the use of shorter tools and eliminating the need to transfer parts to other machines. The side head allows for side milling without a right-angle head and supports pinch-turning of thin-walled aerospace components like engine casings.

Specifications

| Item / Model |

VHL-1200ATC

Request a Quote

|

VHL-1200ATC-II

Request a Quote

|

VHL-1600ATC

Request a Quote

|

VHL-2000ATC-I+ ATC-II

Request a Quote

|

VHL-3000ATC-II

Request a Quote

|

|---|---|---|---|---|---|

|

Capacities |

|||||

|

Maximum Swing |

63″ |

63″ |

78.7″ |

98.4″ |

137.8″ |

|

Std. Turning Diameter |

55.1″ |

55.1″ |

63″ |

90.55″ |

118.1″ |

|

Max. Turning Diameter |

63″ |

63″ |

71″ |

98.4″ |

133.8″ |

|

Max. Cross Travel X1 Axis |

– 15.7″ ~ + 34.4″ |

– 15.7″ ~ + 34.4″ |

– 23.6″ ~ + 40″ |

– 23.6″ ~ +53.14″ |

– 59.1″ ~ +71.8″ |

|

Max. Longitudinal Travel Z1 Axis |

35.4″ |

47.2″ |

47.2″ |

37.4″ (ATC), 47.2″ (ATC-I), 55.1″ (ACT-II) |

59.1″ |

|

Max. Cross Travel for Horizontal Ram X2 Axis |

31.5″ |

31.5″ |

31.5″ |

37.4″ |

39.06″ |

|

Max. Longitudinal Travel for Horizontal Ram Z2 Axis |

39.4″ |

63″ |

70.86″ |

39.4″ (ATC), 55.1″ (ATC-I), 63″ (ATC-II) |

94.5″ |

|

Max. Cross Rail Travel |

31.5″ |

47.2″ |

55.1″ |

45.27″ (ATC), 61″ (ATC-I), 61″ (ATC-II) |

78.7″ |

|

Vertical Ram Distance to Table with Ram Retracted (max./min.) |

59.4″ / 27.9″ |

83.07″ / 35.87″ |

83.1″ / 35.9″ |

80.7″ / 35.5″ (ATC), 96.45″ / 35.5″ (ATC-I), 96.45″ / 35.5″ (ATC-II) |

125.6″ / 46.9″ |

|

Horizontal Ram Distance to Table Center from Ram Face (max./min.) |

47.2″ / 15.7″ |

46.14″ / 15.7″ |

46.14″ / 14.65″ |

61″ / 23.6″ |

68.9″ / 29.84″ |

|

Horizontal Ram Distance to Table from Ram Center (max./min.) |

44.3″ / 4.92″ |

67.92″ / 4.92″ |

75.8″ / 4.92″ |

44.3″ / 4.9″ (ATC), 60″ / 4.9″ (ATC-I), 67.9″ / 4.9″ (ATC-II) |

98.4″ / 3.94″ |

|

Spindle |

|||||

|

Spindle Motor |

60 HP (100 HP opt.) |

60 HP (100 HP opt.) |

100 HP |

100 HP |

100 HP Fanuc, 112 HP Siemens |

|

Spindle Load |

11,000 lbs. |

11,000 lbs. |

17,600 lbs |

22,000 lbs. |

44,000 lbs. |

|

Spindle RPM |

1 – 350 RPM |

1 – 350 RPM |

1 – 250 RPM |

2 – 200 RPM |

1 – 120 RPM |

|

Spindle Bearing Diameter |

24″ O.D. / 18″ I.D. |

18″ |

29.92″ O.D. / 22.8″ I.D. |

36″ O.D. / 27″ I.D. |

40.5″ I.D. / 52.5″ O.D. |

|

Spindle Torque |

9,220 ft./lbs. |

9,220 ft./lbs. |

26,380 ft./lbs. |

41,143 ft./lbs. |

49,659 ft./lbs @ 10 RPM |

|

Manual Chuck |

49″ 4-Jaw Independent |

49″ 4-Jaw Independent |

63″ 4-Jaw Independent |

79″ 4-Jaw Independent |

118″ 8-Jaw Independent |

|

ATC (Vertical Ram) |

|||||

|

Tool Positions |

12 |

12 |

12 |

12 (16, 32, 60 opt.) |

16 |

|

ATC Type |

Umbrella / Electric |

Umbrella / Electric |

Umbrella / Electric |

Umbrella / Electric |

Umbrella / Electric |

|

Tool Mounting |

#50 Taper |

#50 Taper |

#50 Taper |

#50 Taper |

#50 Taper |

|

O.D. Tool Shank Size |

1.25″ |

1.25″ |

1.25″ |

1.25″ |

1.25, 1.5″, 2″ |

|

I.D. Tool Shank Size |

2.5″ |

2.5″ |

2.5″ |

2.5″ |

2.5″ or larger |

|

Tool Change Time |

30 Seconds |

30 Seconds |

30 Seconds |

30 Seconds |

30 Seconds |

|

Max. Single Tool Weight |

110 lbs. |

110 lbs. |

110 lbs. |

110 lbs. |

110 lbs. |

|

Max. Magazine Capacity |

800 lbs. |

800 lbs. |

800 lbs. |

800 lbs. |

1,100 lbs. |

|

ATC (Horizontal Ram – OPTIONAL) |

|||||

|

Tool Positions |

10 |

||||

|

ATC Type |

Umbrella / Electric |

||||

|

Tool Mounting |

#50 Taper |

||||

|

O.D. Tool Shank Size |

1.25″ |

||||

|

I.D. Tool Shank Size |

2.5″ |

||||

|

Tool Change Time |

30 Seconds |

||||

|

Max. Single Tool Weight |

55 lbs. |

||||

|

Max. Magazine Capacity |

550 lbs. |

||||

|

Ballscrews & Axis Motors |

|||||

|

Z1, Z2 Axis Ballscrew Diameter |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

|

X1, X2 Axis Ballscrew Diameter |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

63mm (2.48″) x 10 Pitch |

|

Ballscrew Type |

Class 3 Double Nut |

Class 3 Double Nut |

Class 3 Double Nut |

Class 3 Double Nut |

Class 3 Double Nut |

|

Ballscrew Mounting Type |

Pre-loaded, Double Anchored |

Pre-loaded, Double Anchored |

Pre-loaded, Double Anchored |

Pre-loaded, Double Anchored |

Pre-loaded, Double Anchored |

|

X-Z-C Servo Motor |

X 9HP (2) |

X 9HP (2) |

X 9HP (2) |

X1 & X2 9HP |

X 9HP (2), Z 9HP (2), C 9HP Fanuc |

|

Feeds |

|||||

|

Rapid Traverse Rate |

472 (X), 394 (Z) IPM |

472 (X), 394 (Z) IPM |

472 (X), 394 (Z) IPM |

472 (X1), 394 (Z1) IPM |

236 (X), 394 (Z) IPM |

|

Cutting Feed Rate |

0.01 – 197 IPM |

0.01 – 197 IPM |

0.01 – 197 IPM |

0.01 – 787 IPM |

0.01 – 787 IPM |

|

Positioning Accuracy |

± .0003″ Full Stroke |

± .0003″ Full Stroke |

± .0003″ Full Stroke |

± .0003″ Full Stroke |

± .0003″ Full Stroke |

|

Repeatability |

± .0002″ |

± .0002″ |

± .0002″ |

± .0002″ |

± .0002″ |

|

Vertical & Horizontal Rams |

|||||

|

Vertical Ram Size |

9″ (220mm) Square |

10″ (220mm) Square |

10″ (250mm) Square |

||

|

Vertical Ram Tool Interface |

BT-50 Taper |

BT-50 Taper |

BT-50 Taper |

||

|

Horizontal Ram Size |

10″ (250mm) Square |

10″ (250mm) Square |

10″ (250mm) Square |

||

|

Horizontal Ram Tool Interface |

BT-50 Taper or 4 Position Turret opt. |

BT-50 Taper or 4 Position Turret opt. |

BT-50 Taper or 4 Position Turret opt. |

||

|

C Axis & Live Tools (opt. for both Rams) |

|||||

|

Spindle Motor |

15 HP (20, 25, 30 opt.) |

15 HP (20, 25, 30 opt.) |

15 HP (20, 25, 30 opt.) |

20 HP (25, 30, 35 opt.) |

20 HP |

|

Drive System |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

Spindle RPM |

2,400 |

2,400 |

2,400 |

2,400 |

2,400 |

|

Tool Shank Type |

BT-50 |

BT-50 |

BT-50 |

BT-50 |

BT-50 |

|

C Axis Contouring |

.001° |

.001° |

.001° |

.001° |

.001° |

|

General |

|||||

|

Coolant Tank Capacity |

200 Gallons |

200 Gallons |

200 Gallons |

400 Gallons |

500 Gallons |

|

Coolant Pump Motor |

1.33 HP and .75 HP |

1.33 HP and .75 HP |

1.33 HP and .75 HP |

1.33HP x 22 & 4HP x 1 |

4 HP |

|

Machine Weight |

90,000 lbs. est. |

100,000 lbs. est. |

100,000 lbs. est. |

135,000 lbs. est. |

218,000 lbs. est. |

|

Floor Space (std. machine) |

413″ x 236″ x 240″ |

413″ x 236″ x 264″ |

478″ x 251″ x 256″ |

570″ x 255″ x 255″-295″ |

231″ x 395″ x 314″ |

|

Machine Power Source |

208/220V, 3 Phase, 250 Amps* |

208/220V, 3 Phase, 250 Amps* |

208/220V, 3 Phase, 250 Amps* |

440/460/480V, 3 Phase, 250 Amps* |

208/220V, 3 Phase, 400 Amps* |

|

Hydraulic Pump Motor |

3 HP |

3 HP |

3 HP |

7.5 HP |

3 HP |

* Consult AMT or local distributor for exact power requirements with selected options.