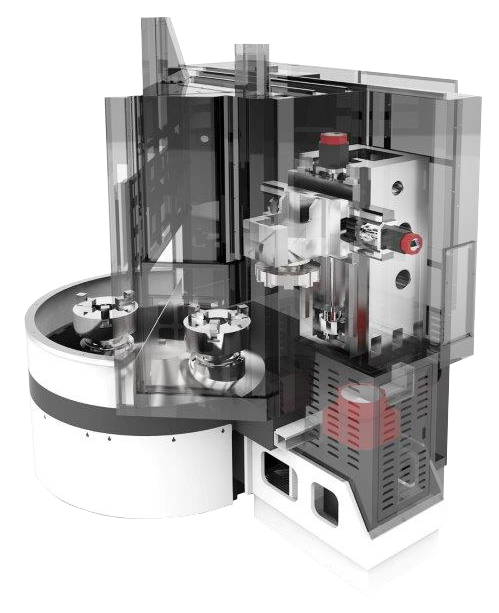

You Ji CY Series – Vertical Turning Centers with Automatic Pallet Changers

The You Ji CY-550H+APC vertical turning center is a compact, high-precision, CNC machine designed with a built-in automatic pallet changer for continuous, uninterrupted production — ideal for both stand-alone and integrated production line environments. Built for stability and accuracy, the CY-550H+APC features a rigid vertical column and base constructed from Meehanite castings. These heavily ribbed structures effectively minimize thermal distortion and absorb vibration, ensuring consistent machining performance. The X- and Z-axis linear guideway system enables rapid traverse rates of 787 in/min (20 m/min), with box way configurations also available to suit heavier cutting applications. Class 3 precision ballscrews are directly coupled to servo motors eliminating belts or gears to provide smoother, more accurate motion and reduced maintenance.

An 8-position hydraulic turret (with optional 10-position configuration) delivers fast indexing at just 0.5 seconds, with automatic shortest-path tool selection for optimized cycle times. A live tooling turret is also available as an option for added versatility. A standard chip wash system helps clear chips from the machining area into the conveyor, maintaining a clean and efficient cutting environment.

The CY-550H+APC can be extensively customized to meet specific production needs, offering a broad range of options such as a C-axis and live tools, Y-axis capability, radial and axial live tool heads, automatic tool presetter, specialized chucking and fixturing solutions, and fully automated loading/unloading systems.

Specifications

| Item / Model |

CY-550H+APC

Request a Quote |

|---|---|

|

Turning Dia. (in.) |

∅21.65 (std.), ∅27.5 (max.) |

|

Max. Swing (in.) |

29.5″ |

|

Max. Cutting Height (in.) |

19.1″ |

|

Z Axis Travel (in.) |

19.7″ |

|

Rail Travel (in.) |

Fixed |

|

Ram to Table Max (in.) |

35.6″ |

|

Indexing Time |

0.5 seconds |

|

Spindle Motor (Fanuc P Series) |

30 HP (Double Wound) |

|

Spindle Motor |

10 HP (15HP opt.) |

|

Spindle Bearing Dia. (in.) |

∅4.72″ |

|

RPM |

4,000 |

|

Y Axis |

Optional |

|

C Axis and live tools |

Optional |

|

Weight (lbs.) |

29,500 lbs. |