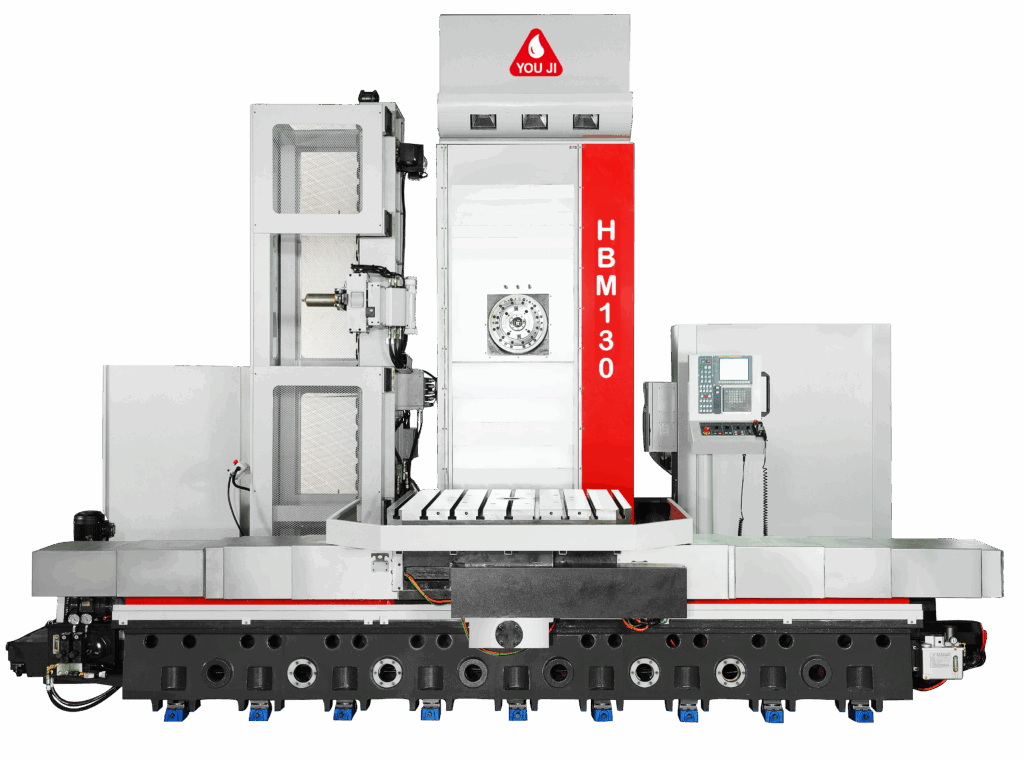

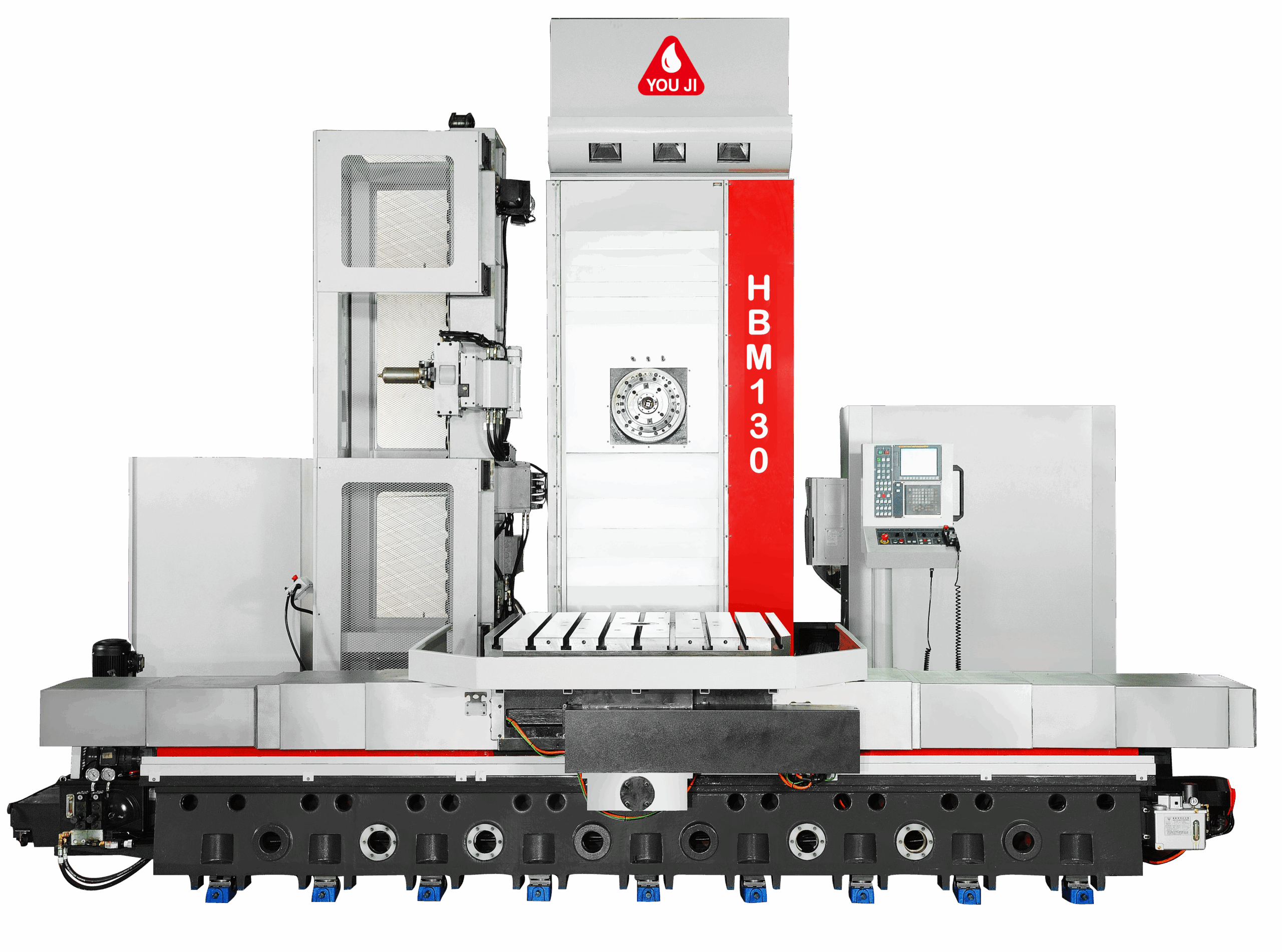

You Ji HBM Series CNC Boring Mills

High-Rigidity Table-Type CNC Boring Mills for Precision Machining of Heavy, Complex Components

The You Ji HBM Series of table-type CNC boring mills is engineered for manufacturers who demand maximum rigidity, accuracy, and long-term reliability when machining heavy, complex workpieces. Designed with a true moving-column Z-axis and fully supported moving-table X-axis architecture, these boring milling machines deliver exceptional geometric stability and ultra-fine surface quality — making them ideal for aerospace structures, energy components, heavy equipment frames, precision machinery bases, molds, dies, and large industrial castings.

Available in models such as the HBM-110 and HBM-130, You Ji horizontal CNC boring machines compete directly with premium global brands such as Fermat, TOS Varnsdorf, and Giddings & Lewis, while offering higher base casting mass, hydrostatic table options, triple-cooled high-torque spindles, and precision hand-scraped ways at a substantially more competitive cost. These benefits make the You Ji HBM Series one of the most capable and value-driven new CNC boring machine platforms on the market for manufacturers seeking reliability, accuracy, and return on investment.

Key Features

- Moving-Column / Fully Supported Moving-Table Architecture

Zero-overhang X-axis design maintains accuracy and rigidity for heavy-load CNC boring operations. - Massive Meehanite Base Castings

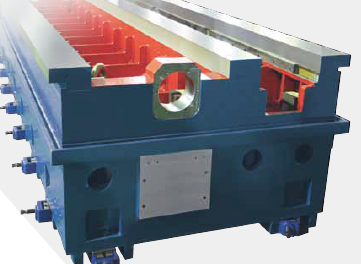

75,000–130,000 lb machine structures provide outstanding damping for ultra-stable machining. - Precision Box Ways & Hydrostatic Guideways

Hand-scraped Turcite-B surfaces on all box ways; triple-box hydrostatic X-axis on HBM-130 for superior rigidity under extreme table loads. - High-Torque, Triple-Cooled Spindles

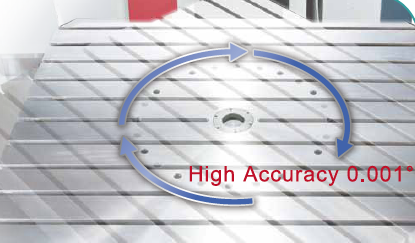

Chrome-moly quill construction and triple-cooling enable heavy roughing, long-cycle finishing, and deep boring with excellent thermal control. - Hydrostatic B-Axis Rotary Table

Dual-pinion drive with ultra-high resolution encoders supports 33,000–55,000+ lb loads (model-dependent) with exceptional positioning accuracy. - Heavy-Duty Automatic Tool Changer

60-tool ATC standard; 80- and 120-tool configurations optional for complex high-mix machining. - High-Precision Axis Components

Large-diameter, pre-tensioned ballscrews and direct-drive servomotors maintain high-accuracy positioning on all linear axes. - Integrated Cooling, Chip Management & Guarding

Programmable air blast, 300 PSI through-spindle coolant, screw-plus-caterpillar chip conveyors, and tall table guards support continuous heavy machining. - Advanced Fanuc CNC Control

Fanuc 31iM-B or 31iM-B Plus with Manual Guide i, Alpha-i servos, 1,000,000-pulse encoders, and advanced contour control. - Highly Customizable Platform

Extended X/Y/Z/W travels, increased table loads (up to 70,000 lbs), large rotary tables, probing systems, high-pressure coolant, and pallet changers.

Specifications

| Item / Model |

HBM-110

Request a Quote |

HBM-130

Request a Quote |

|---|---|---|

|

Photos |

|

|

|

X Axis Travel |

78.7″ |

118″ |

|

Y Axis Travel |

70.8″ |

102.4″ |

|

Z Axis Travel |

49.2″ |

65″ |

|

W Axis Travel |

19.7″ |

29.5″ |

|

Spindle Bar |

Ø4.33″ |

Ø5.12″ |

|

Table Size |

55.1″ x 63″ |

70.86″ x 86.6″ |

|

Table Load Capacity |

22,000 lbs. (33,000 opt.) |

55,000 lbs. |

|

Spindle Drive |

2 Speed Gear Box |

2 Speed Gear Box |

|

Spindle HP |

35 HP |

60 HP |

|

Spindle RPM |

0 – 3,000 RPM |

0 – 2,500 RPM |

|

ATC Capacity |

40 (60 / 80 / 120 opt.) |

60 (80 / 120 opt.) |

|

Weight (Base Machine Only) |

75,000 lbs. |

130,000 lbs. |

Flood coolant system with programmable air blast

Air blast for spindle

Auto lubrication with alarm

Automated chip removal system with chip conveyors (1 screw type + 1 caterpillar type)

Halogen work lamp

2 speed geared head with spindle / headstock cooler

Remote handwheel

Heat exchangers for control cabinets

Hydraulic counterbalance for headstock

Rigid tapping

B axis rotary table (.001 degree)

60 tool ATC

300 PSI coolant through spindle

Heidenhain linear scales

B axis rotary scale

X axis 3500mm travel

X axis 4000mm travel

X axis 4500mm travel

X axis 5000mm travel

X axis 5500mm travel

Y axis travel extension to 118”(3000mm)

Y axis travel extension to 133.8” (3400mm)

Z axis travel extension to 80.7” (2050mm)

Elevating operators platformB axis table load increase to 70,000 lbs

Rotary table 98.4” x 70.8”

Rotary table 118.1” x 98.4”

Rotary table 118.1” x 98.4” with 80,000 lbs table load

Marposs VOP optical wireless part probe installed with training

Marposs VOTS optical wireless tool setter installed with training

Marposs VOP part probe + VOTS tool setter PACKAGE installed with training

Marposs WRP radio wireless part probe installed with training

Marposs WOTS radio wireless tool setter installed with training

Marposs WRP radio part probe + WOTS radio tool setter PACKAGE installed with training

Marposs ML75P laser tool setter installed with training

Auto Tool Presetter (Renishaw RTS radio wireless, installed)

Renishaw NC4+ F145/85 3.35” laser tool setter (hardware only kit)

Renishaw NC4+ F145/85 3.35” laser tool setter installed with 2 days of training

Renishaw RMP-60 radio part probe for 2-D surfaces (hardware only kit)

Renishaw RMP-60 radio part probe installed with 2 days training

Renishaw RMP-600 radio part probe for 3-D surfaces (hardware only kit)

Renishaw RMP-600 radio part probe installed with 2 days training

Fanuc AC Drive for 6th Axis and 6th Axis interface (Rotary table on top of B axis table)

High pressure coolant thru spindle 1000 PSI (includes twin tower bag filters)

Coolant chiller

440 / 460 / 480 Volt operation

Spindle extension sleeve (300mm)

Spindle extension sleeve (500mm)

Facing head (manual) 500mm diameter, 820mm max cut diameter

Facing head (manual) 630mm diameter, 1030mm max cut diameter

Facing head (manual) 800mm diameter, 1360mm max cut diameter

Angle Plate 15.7” x 15.7” x 27.5”

Angle Plate 19.7” x 19.7” x 39.4”

Angle Plate 23.6” x 23.6” x 51.2”

Angle Plate 27.5” x 28” x 63”

Angle Plate 31.5” x 39.4” x 84.6”

Angle Plate 39.4” x 47.2” x 98.4”

80 Tool ATC

120 tool ATC

Right angle head (manual) 50 taper input / 50 taper output

Multi-angle head (manual) 50 taper input / 50 taper output

The You Ji HBM Series provides metal-cutting professionals with the structural stability and machining performance required for demanding production environments. Whether roughing heavy castings, finishing large precision bores, machining tall workpieces, or performing multi-face operations on heavy components, these machines consistently deliver high-accuracy results with minimal thermal drift and outstanding repeatability.

Key performance benefits include:

- Exceptional structural rigidity for heavy cuts and deep boring

Massive Meehanite cast-iron construction—75,000 lbs on the HBM-110 and 130,000 lbs on the HBM-130 —ensures stable cutting forces, high rigidity, and reduced vibration on challenging materials and large tooling. - Full table support across the entire X-axis stroke

The fully supported, no-overhang table design eliminates the need for outriggers and preserves machining accuracy under heavy dynamic loads—critical for oversized aerospace, mold, and energy components. - High-accuracy machining from premium box-way and hydrostatic structures

Dual box guideways on the HBM-110 X/Z axes and a unique triple-box hydrostatic guideway on the HBM-130 deliver exceptional rigidity and long-term geometric stability. - Precision through Heidenhain scales on all axes

Standard Heidenhain linear scales provide ±0.0003″ positioning accuracy and ±0.0002″ repeatability for consistent precision on large-scale machining programs. - High-torque, triple-cooled spindle systems for heavy cutting

- HBM-110: 35 HP, 0–3000 RPM, 836 ft-lbs of torque at 218 RPM

- HBM-130: 60 HP, 0–2500 RPM, 1452 ft-lbs at 218 RPM

Triple cooling (oil-cooled spindle sleeve, air/oil spindle bearings, oil-cooled quill) ensures thermal stability during long cycle times.

- High-accuracy hydrostatic rotary B-axis

Hydrostatic table with dual-pinion drive delivers ±7.5 arc-second accuracy and ±5 arc-second repeatability—the best in its class for precision multi-face machining. - Cycle time reduction with fast axis movement and advanced controls

Rapid traverse rates up to 394 IPM and Fanuc 31iM-B Plus controls with AICC-II contouring optimize cycle times while maintaining high-accuracy profiling. - Wide range of customization options

Extended travels, larger rotary tables, pallet changers, automatic part probing, 80- or 120-tool ATCs, heavier table loads (up to 70,000 lbs), and other enhancements enable the HBM Series to be tailored to any production environment.

With this combination of rigidity, thermal stability, and precision feedback, You Ji HBM Series machines provide long-term reliability and superior results for complex heavy-part machining.

Ideal Cutting Applications

- Aerospace machining

Bulkheads, frames, landing gear components, titanium and steel structural elements requiring precision bores and multi-face machining. - Energy sector components

Turbine housings, generator frames, valve bodies, compressor cases, and power-generation castings requiring heavy-duty CNC boring. - Heavy machinery & industrial equipment

Large weldments, machine bases, gearbox housings, structural plates, and hydraulic manifolds. - Precision mold & die manufacturing

Large mold bases, deep cavities, and precision surfaces requiring ultra-fine finishes and reliable thermal stability. - Defense & transportation

Armored vehicle components, rail systems, bogie frames, drivetrain housings, and precision boring of steel structures. - General large-scale CNC boring & milling

Any application requiring stable, accurate machining of heavy, tall, or large-footprint components.