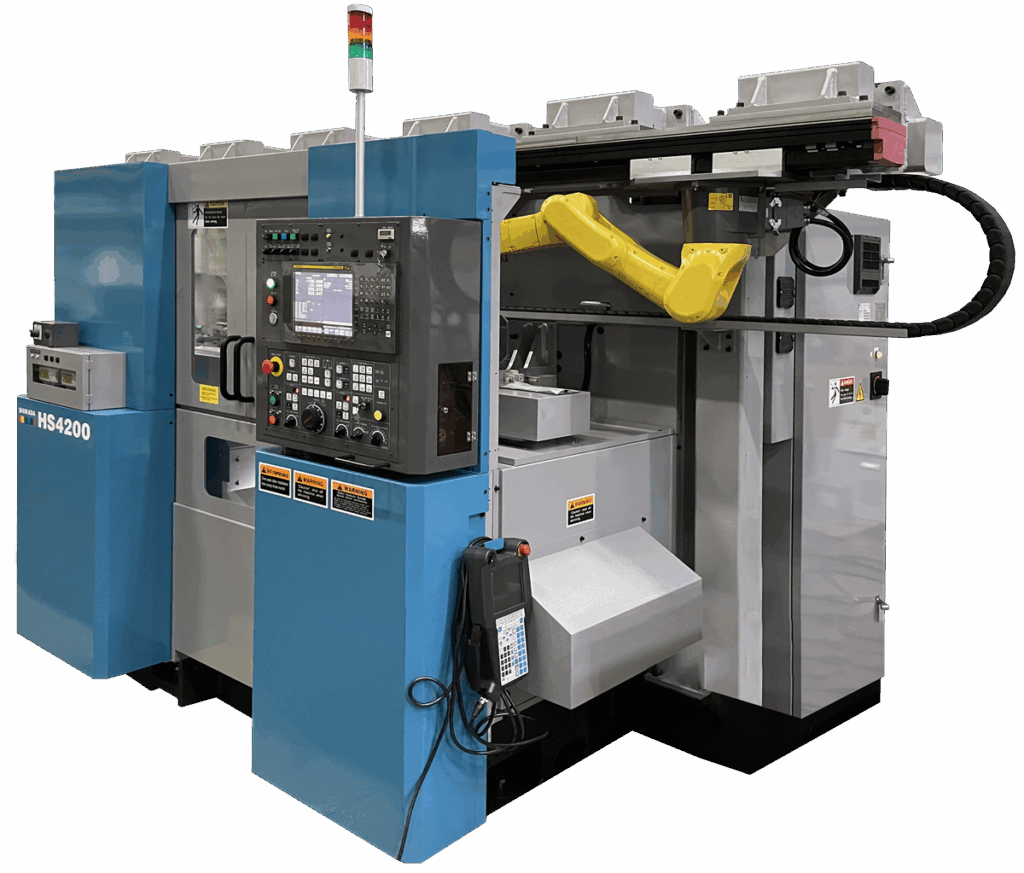

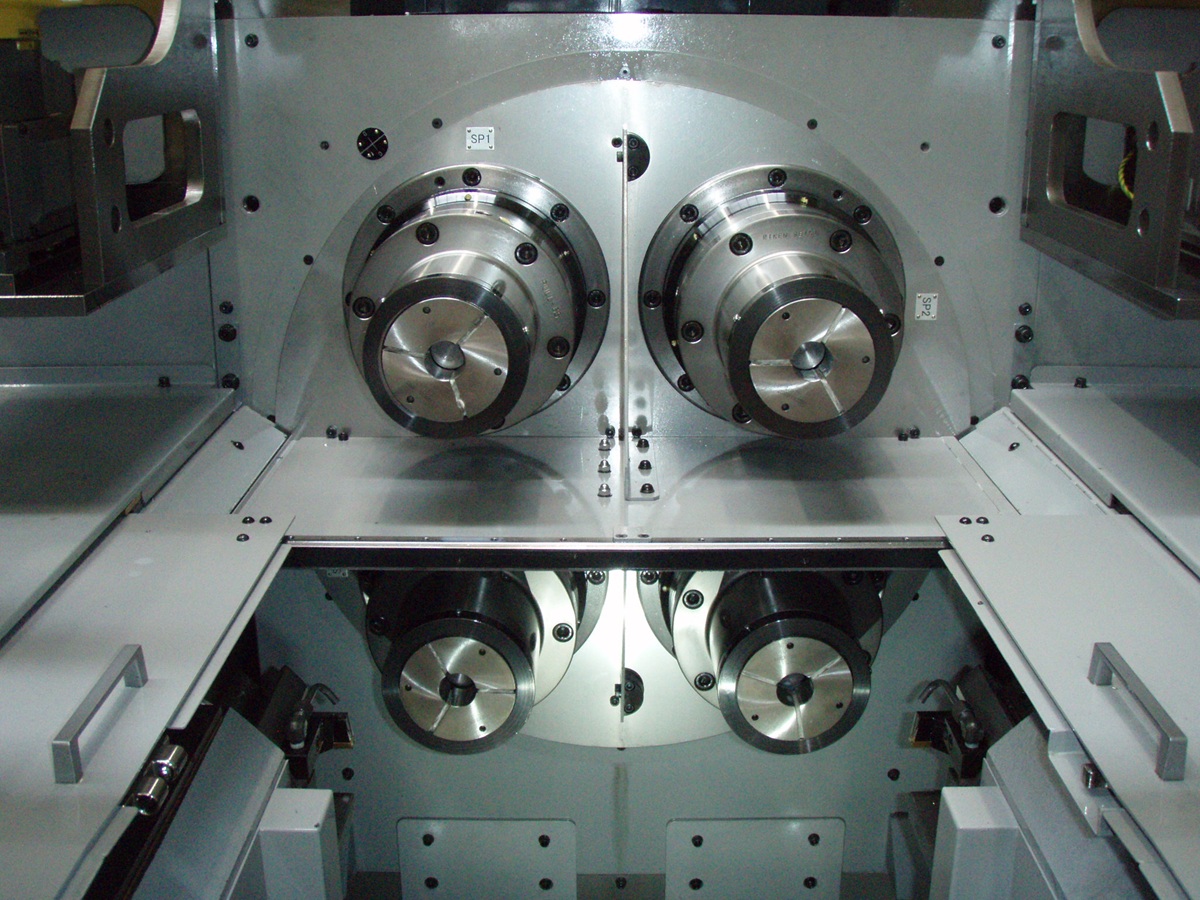

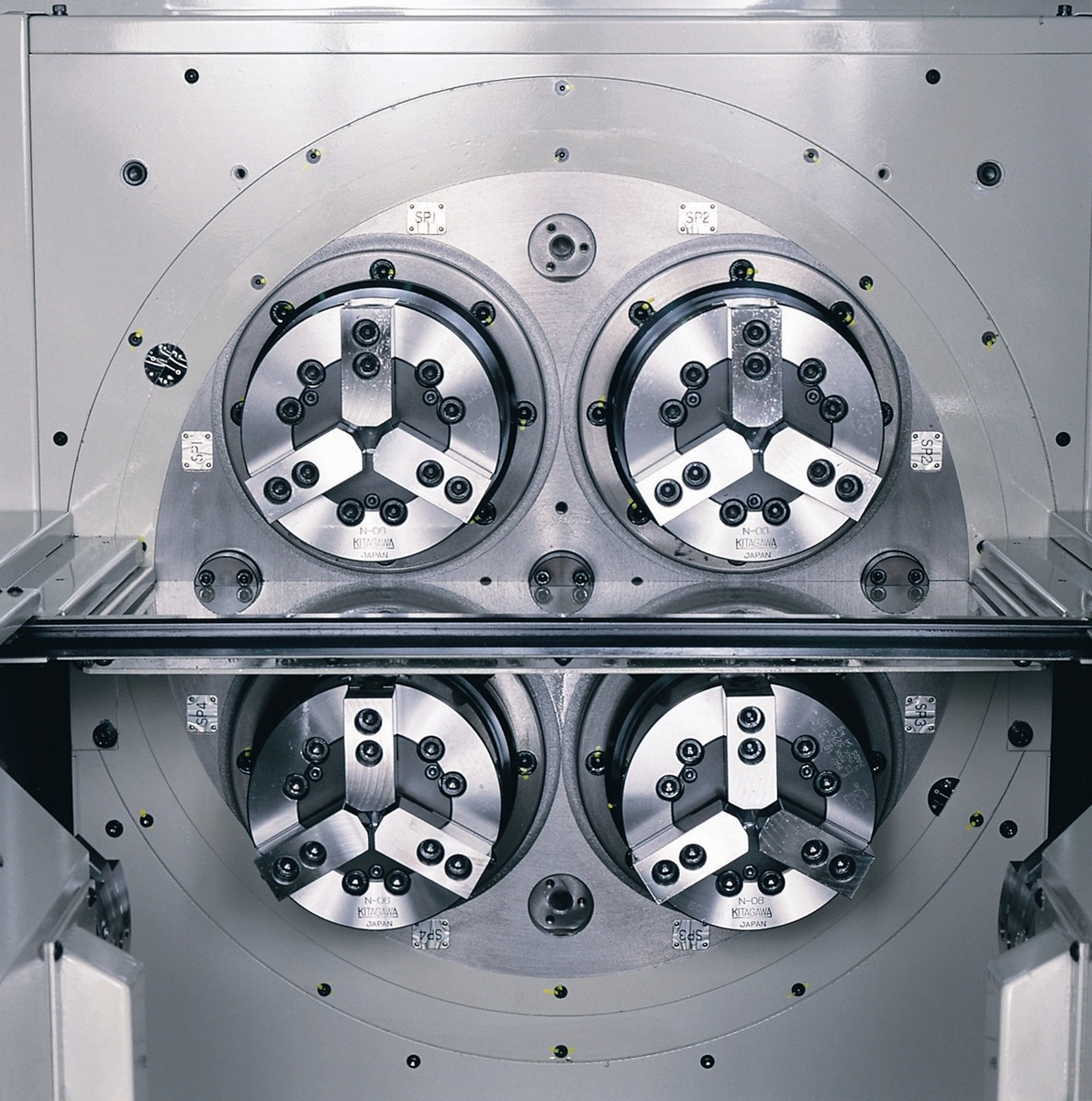

Shimada Kitako HS4200 Series – 4 Spindle Automatic Lathes

High-Output 4-Spindle CNC Chuckers for Near-Zero Idle Time Production

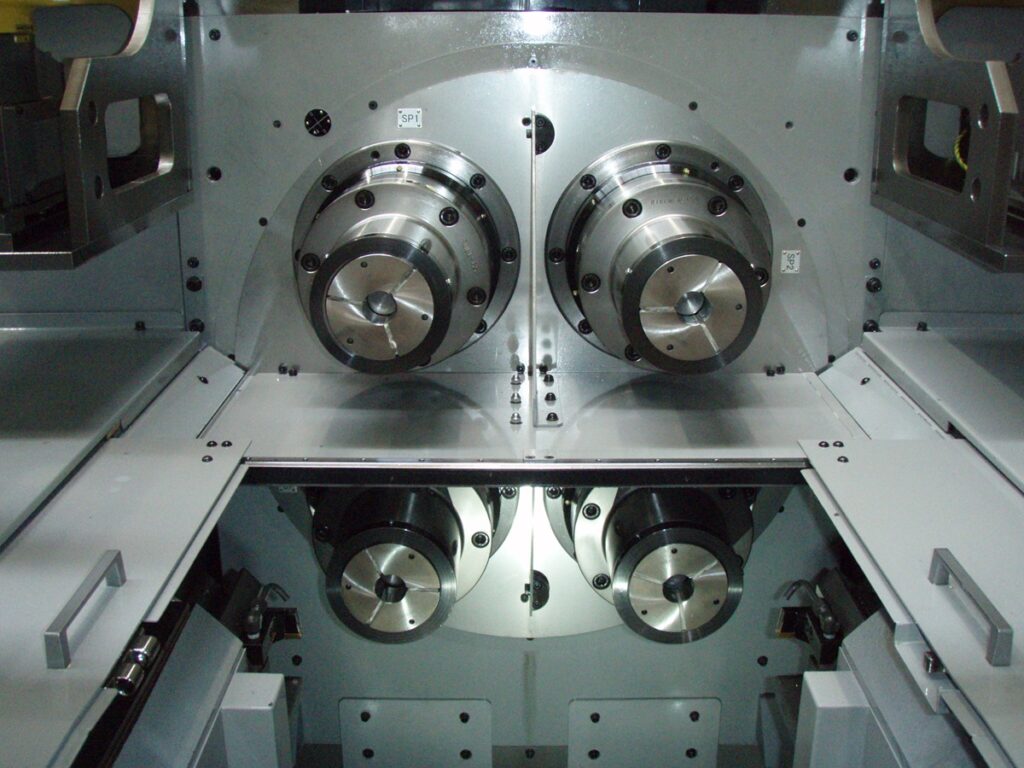

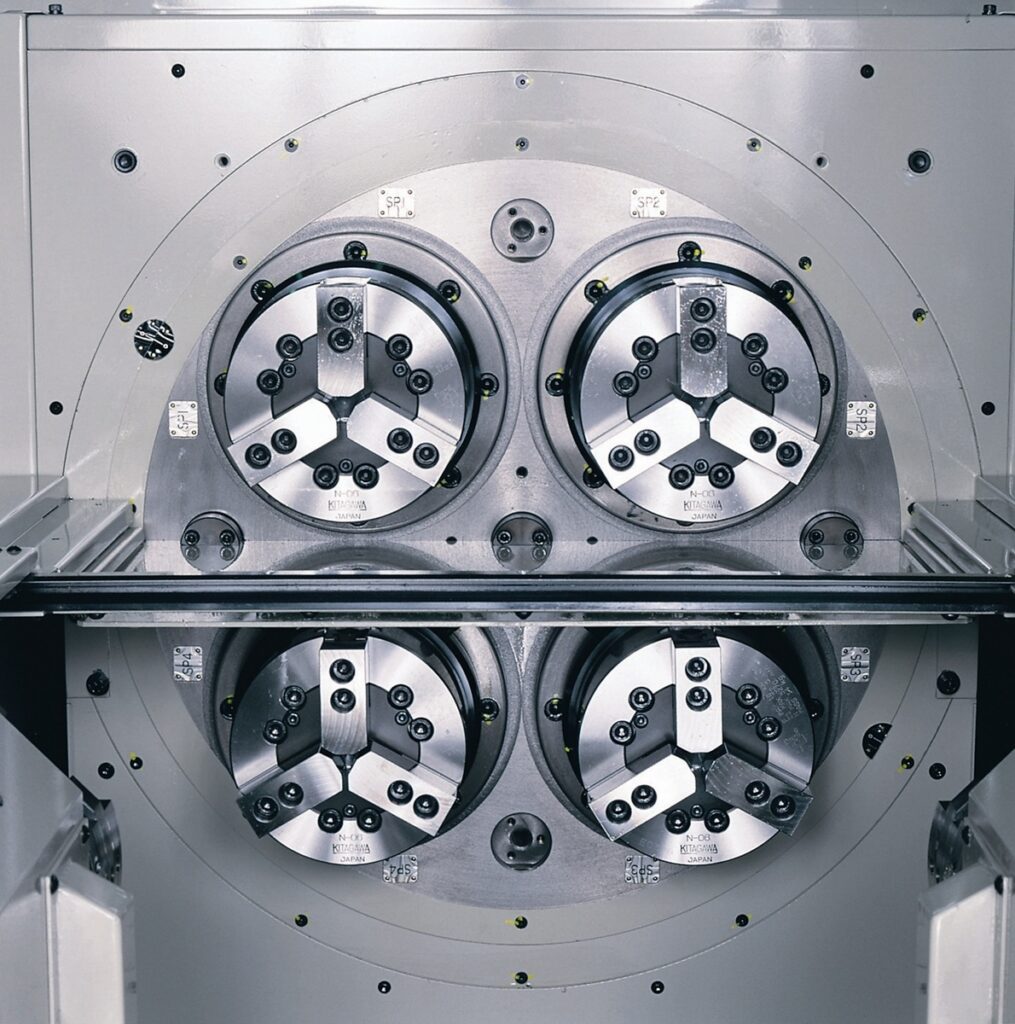

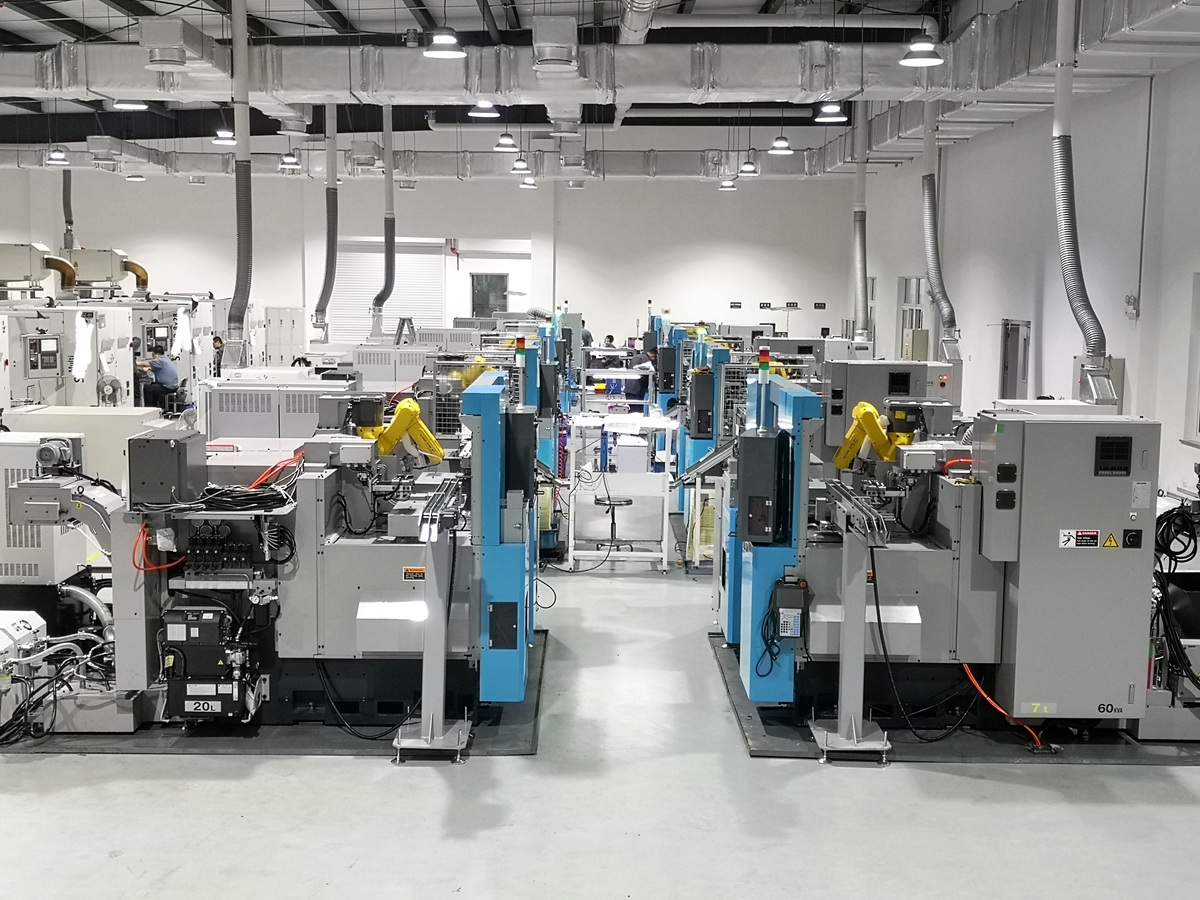

The Shimada Kitako HS4200 Series consists of 4-spindle, 2-turret (2NC) CNC horizontal chuckers engineered for high-volume, continuous-flow production. A high-speed indexing drum rotates 180° to switch spindles—two are always cutting while two are loading and unloading—reducing idle time to nearly zero and dramatically increasing throughput per square foot.

Built on rigid box-way construction with dual-turret machining and optional live tooling, the HS4200 platform delivers exceptional efficiency for manufacturers producing rotational parts in large quantities. Every model is automation-ready for gantry loaders, robot tending, and complete turnkey production cells.

Key Features

- 4-Spindle Indexing System

Enables 180° indexing so two spindles machine while two spindles load/unload - Dual Turrets (2NC)

Each turret supports 8 stations (or 10 for live tooling), enabling simultaneous machining - Live Tooling Options

Available on M-designated models for multi-process capability - Automation-Ready Construction

Compatible with directly mounted robots or high-speed gantry loaders - Generous Machining Envelope

- Max machining diameter: Ø7.87″ (Ø200 mm)

- Chuck options: 8″ or 10″

- X-axis travel: 6.29″ (160 mm)

- Z-axis travel: 9.05″ (230 mm)

- Performance Specifications

- Rapid feed rate: 78.72 ft/min (24 m/min)

- Spindle motor: 11/15 kW × 2

- Speed range: 45–4,500 rpm

- Compact, Rigid Machine Base

- Floor space: 94.48″ × 126.77″ (2400 mm × 3220 mm)

- Machine weight: 16,535 lbs (7,500 kg including loader)

Available Models in the HS4200 Series

The HS4200 Series is offered in five distinct model configurations so manufacturers can choose the layout that aligns with their part needs and automation strategy.

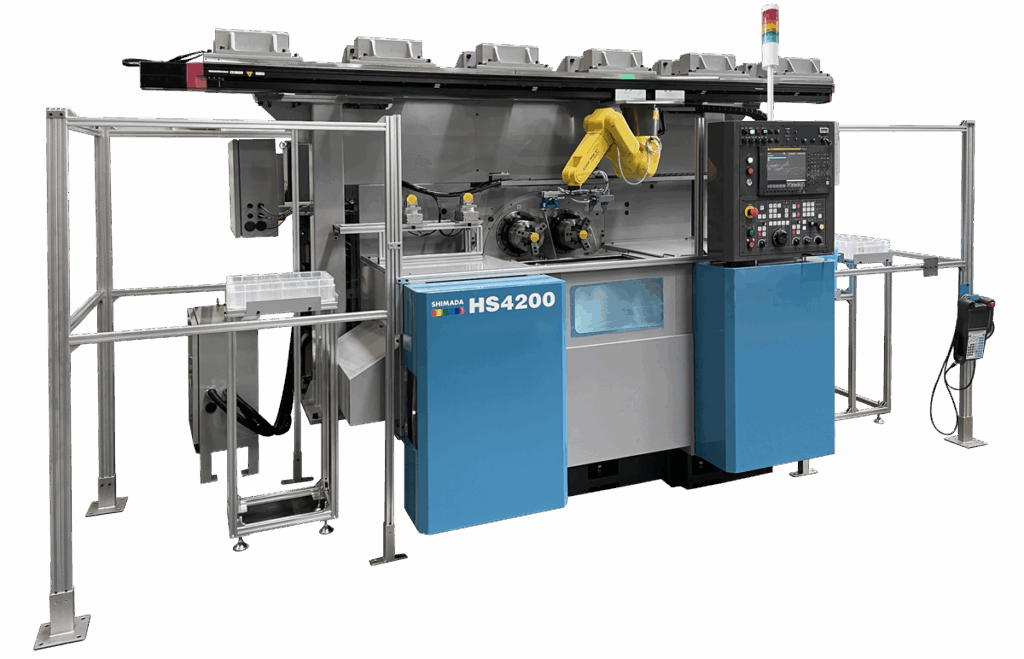

HS4200i – Standard Gantry Loader Model

The base 4-spindle configuration equipped with a standard high-speed gantry loader for efficient, repeatable part handling.

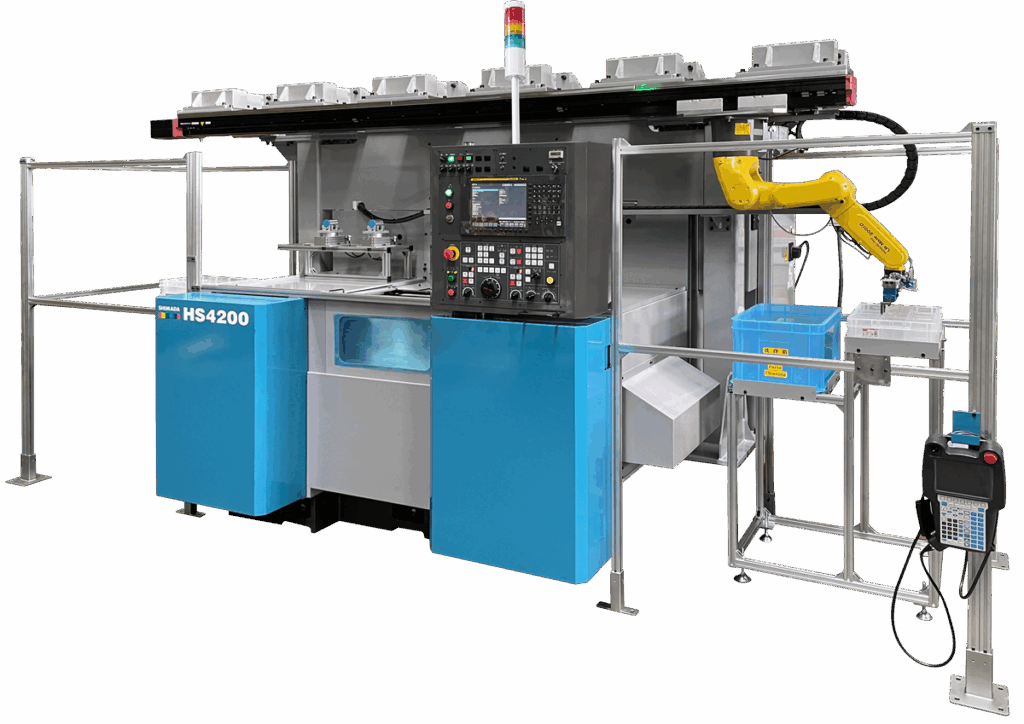

HS4200iM – Gantry Loader + Live Tooling

Adds live tooling capability to the HS4200i, enabling drilling, tapping, and light milling for completing more features in one cycle.

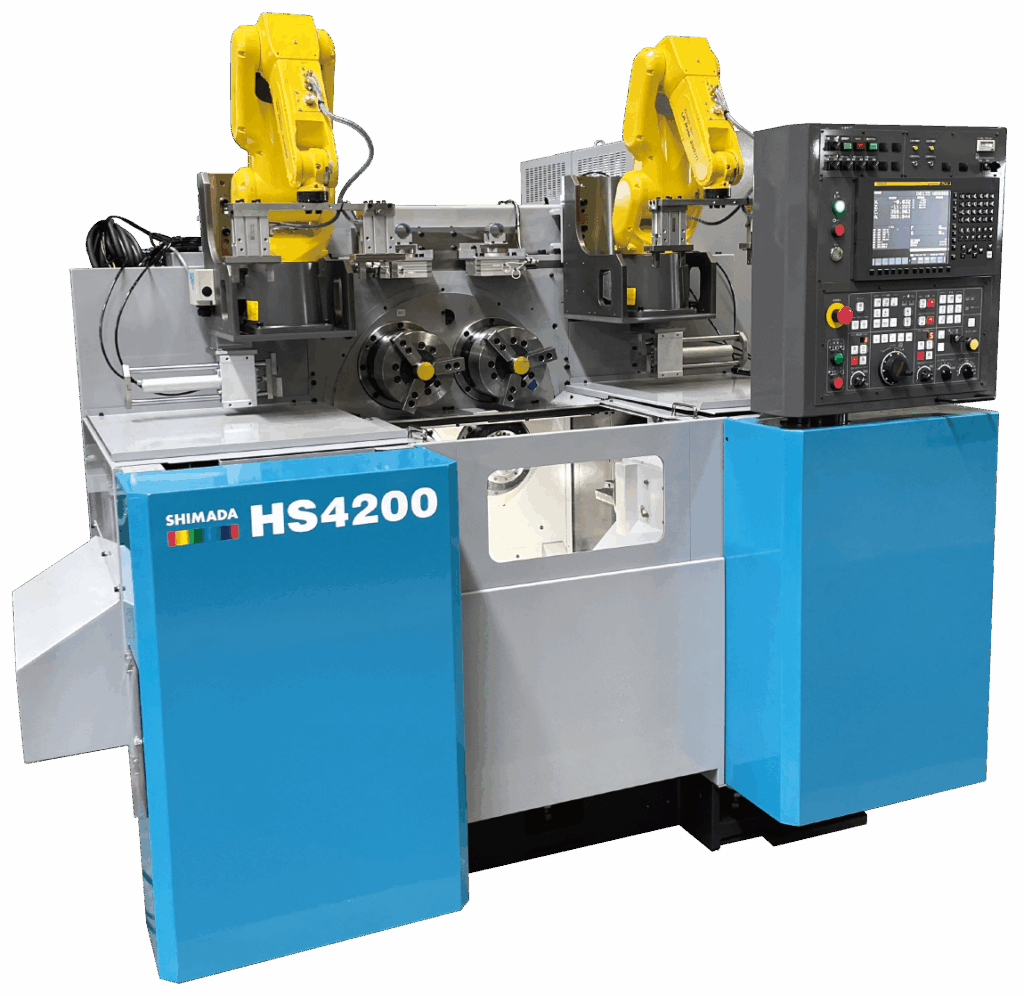

HS4200n – Robot-Ready Configuration

Eliminates the standard gantry and includes a robot-ready mount, ideal for integrators and flexible production cells using 6-axis robots.

HS4200M – Base Model with Live Tooling

Live-tool version of the core HS4200 platform without a gantry, suitable for custom automation, manual loading, or robot integration.

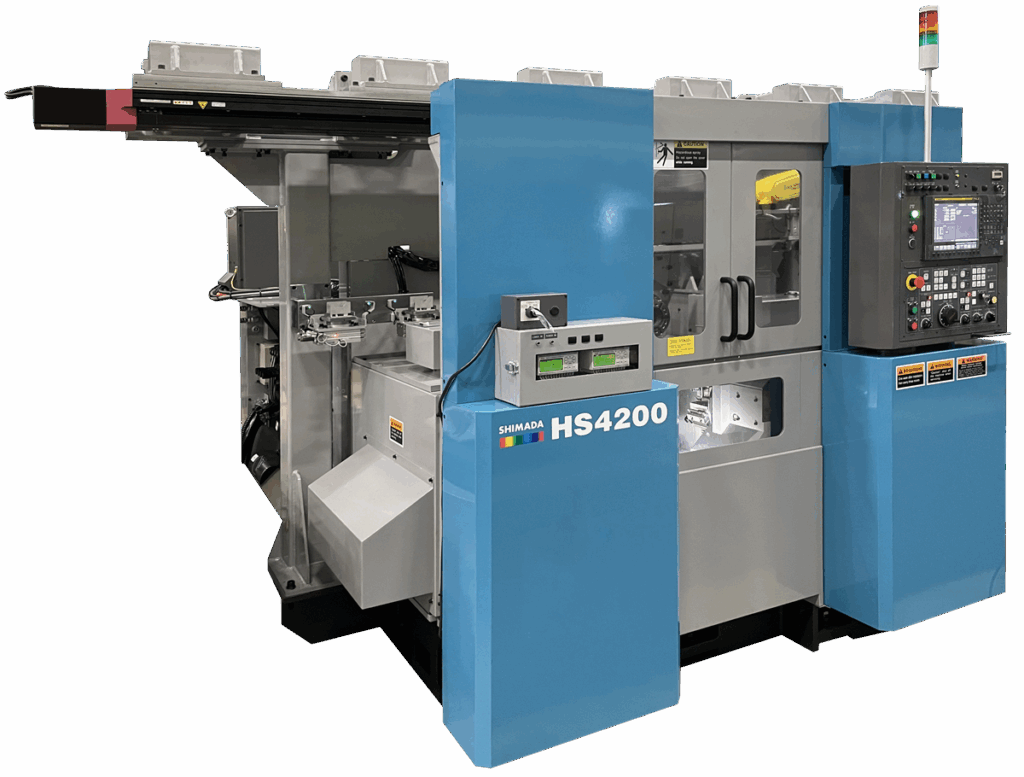

HS4200T – Tailstock Model

Includes a tailstock for supporting longer or shaft-type parts during heavy or simultaneous turning operations.

The Shimada Kitako HS4200 Series gives manufacturers the flexibility to choose the ideal configuration—gantry, robot-ready, live tooling, or tailstock—while maintaining the same core 4-spindle productivity advantage. Absolute Machine Tools can help you evaluate your part prints, recommend the correct HS4200 model, and integrate complete automation for a turnkey production solution.

Specifications

| Item / Model |

HS4200

Request a Quote |

|---|---|

|

No. of Spindles |

4 |

|

X-Axis Travel |

6.29″ (160 mm) |

|

Z-Axis Travel |

9.05″ (230 mm) |

|

Rapid Feed Rate |

78.72 ft./min. (24 M/min.) |

|

Max Machining Diameter |

∅7.87″ (∅200 mm) |

|

Chuck Capacity |

8″ or 10″ (203.2 mm or 254 mm) |

|

Motor |

11/15 kw x 2 |

|

Speed Range |

45 – 4500 IPM (1143mm – 114,300 mm / min.) |

|

No. of Turret Stations |

8 Stations / Gang Tool / Live Tool 10 Stations x 2 |

|

Floor Space |

94.48″ x 126.77″ (2400 mm x 3220 mm) |

|

Machine Weight |

16,535 lbs. (7,500 kg (including loader)) |