Shimada-Kitako 2SI MKII Series – Twin Spindle Single Turret Lathes

Twin-Spindle, Single-Turret CNC Lathes for Simultaneous OP10/OP20 Machining

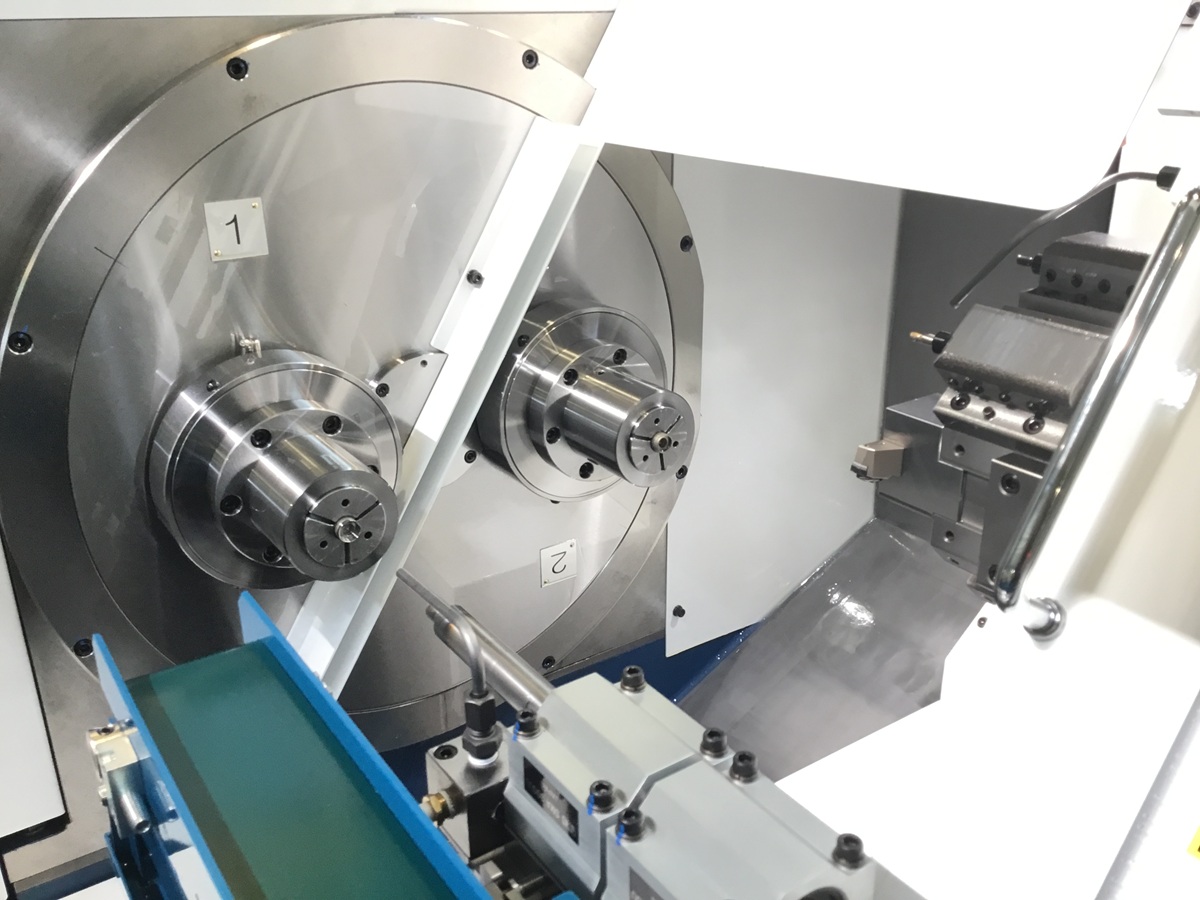

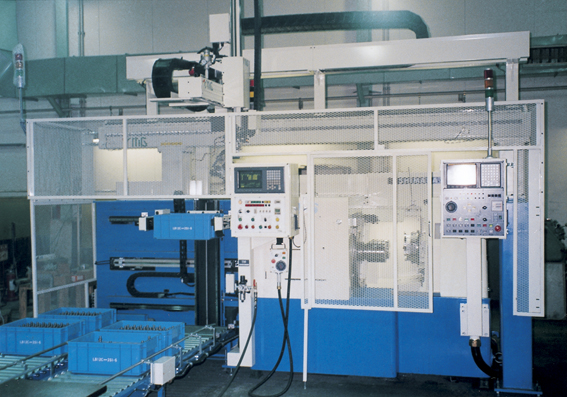

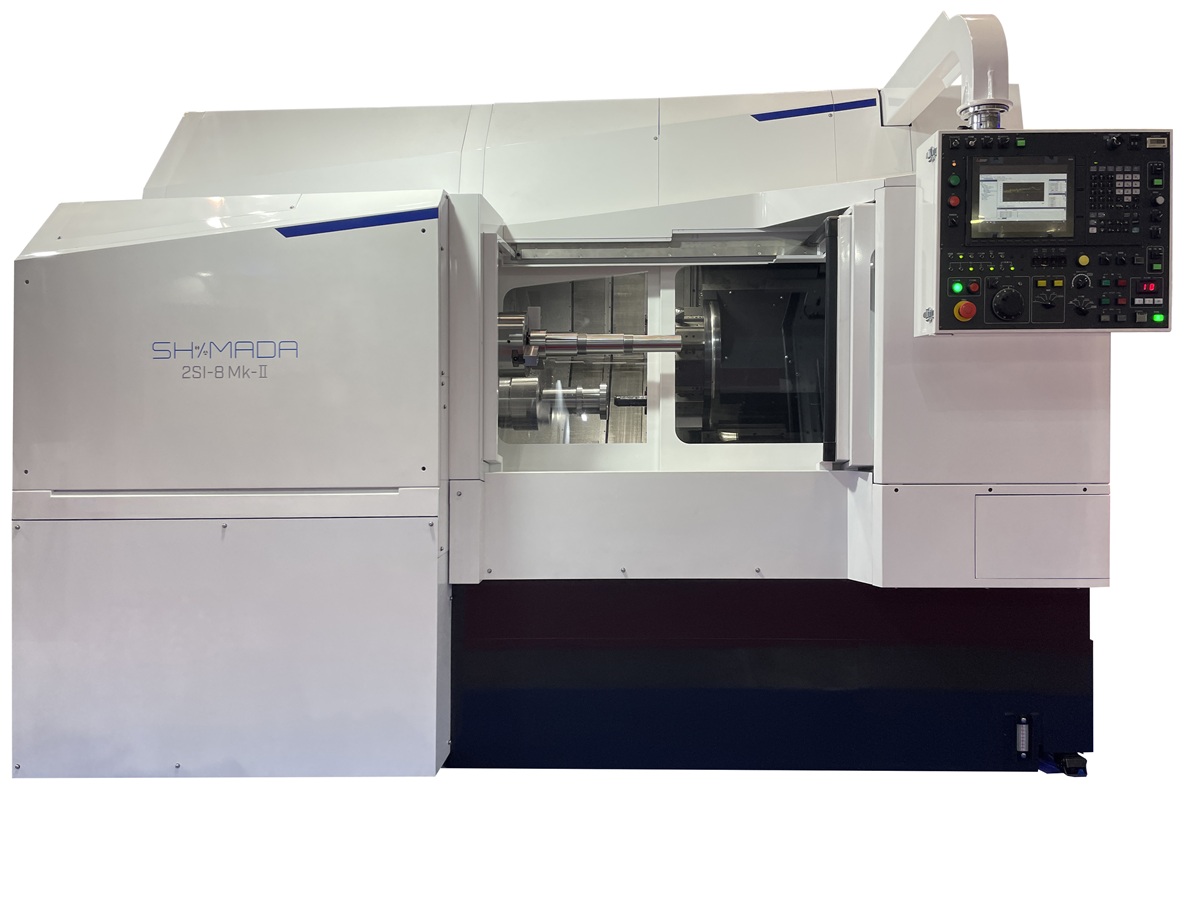

The Shimada-Kitako 2SI MKII Series consists of twin-spindle, single-turret CNC turning centers designed to machine both ends of a workpiece at the same time. While one spindle completes OP10, the second performs OP20, eliminating load/unload idle time and allowing finished parts to exit the machine every cycle. Once both operations are complete, the turret indexes 180°, instantly swapping sides and repeating the process for uninterrupted production flow.

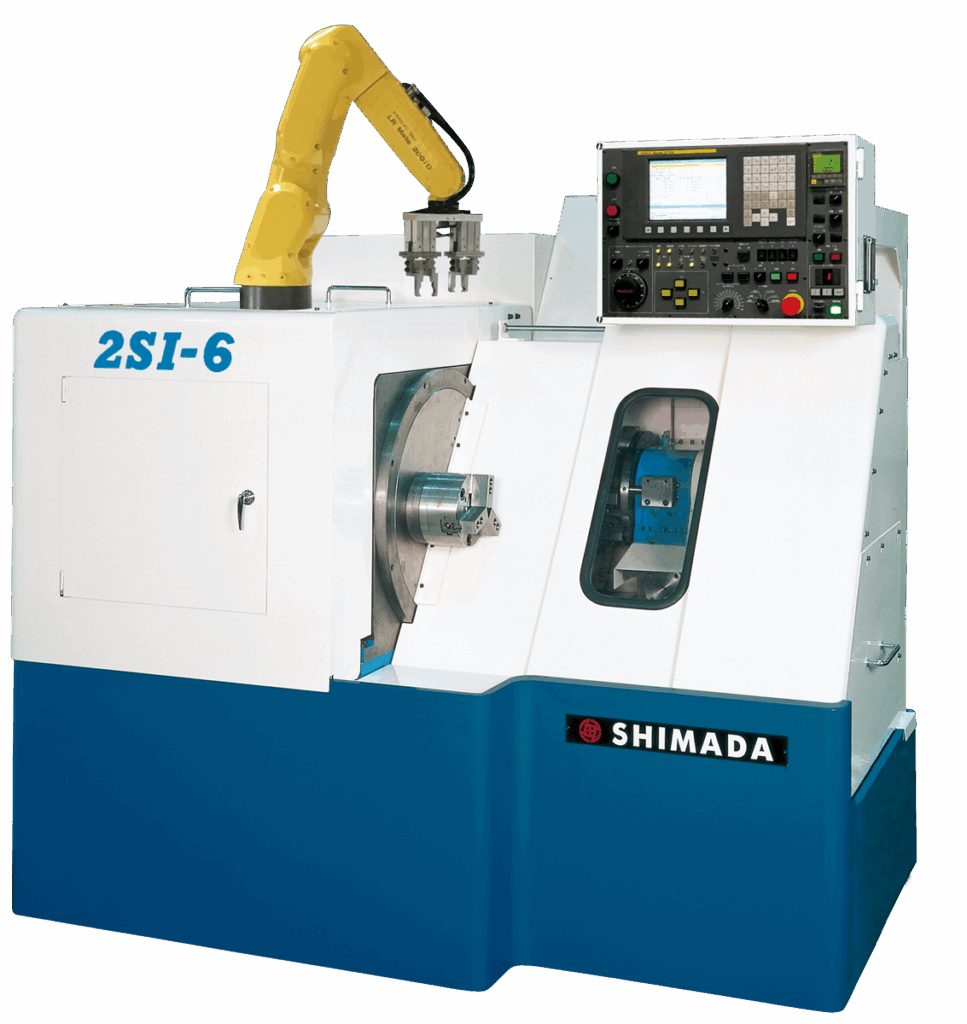

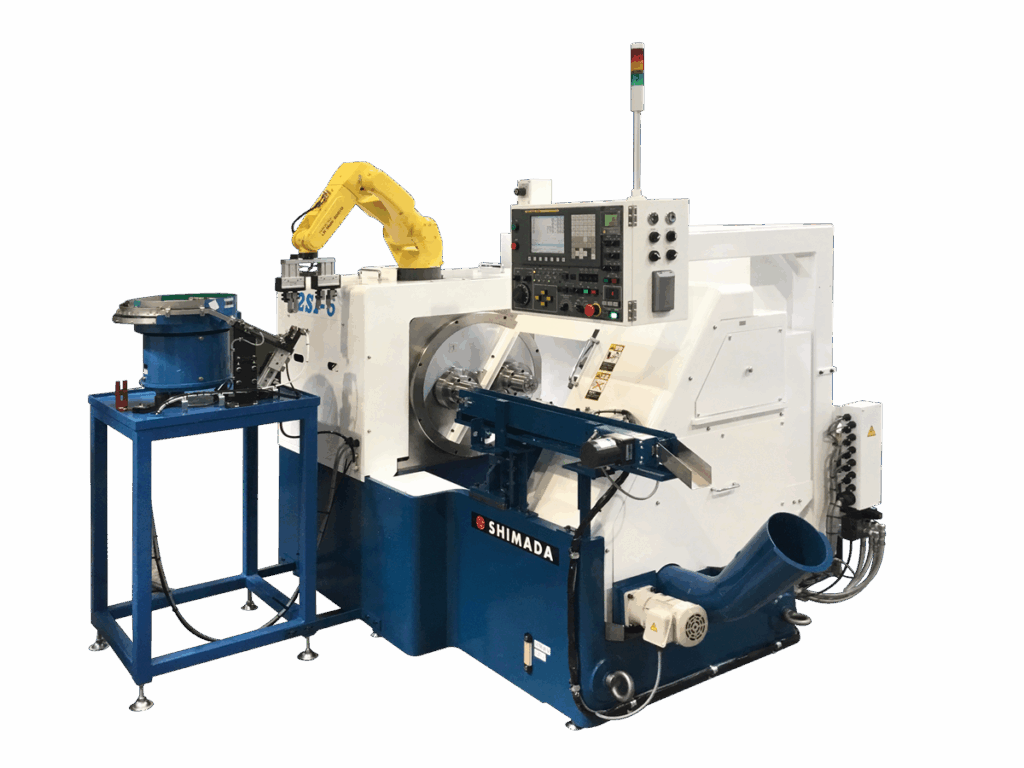

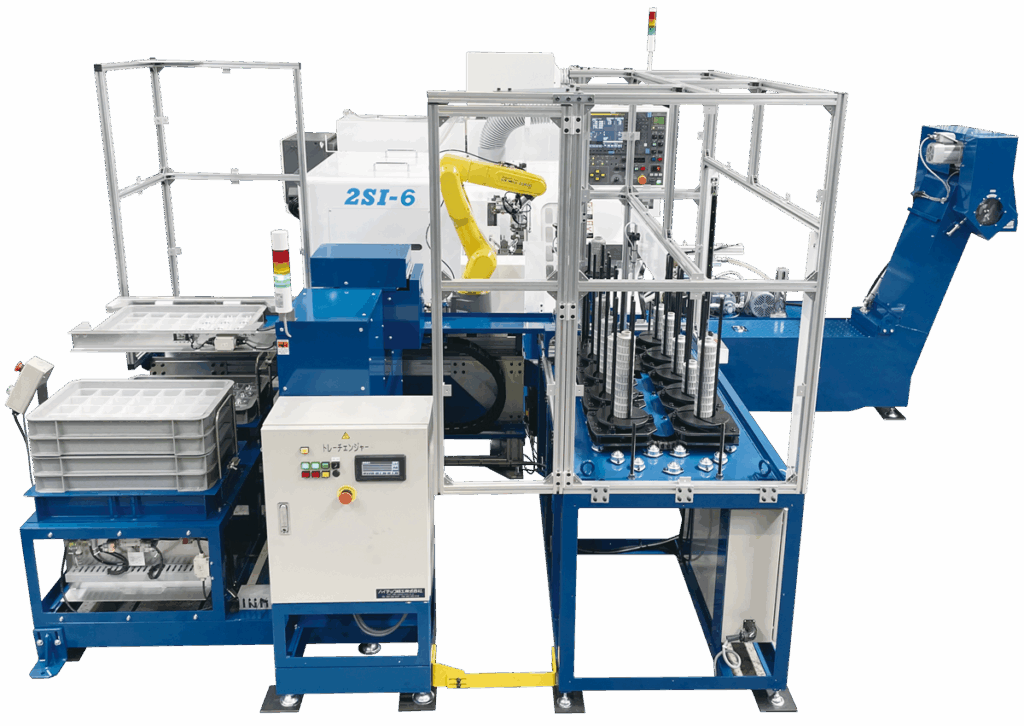

Designed for flexibility, the 2SI MKII Series supports 6″, 8″, and 10″ chuck configurations, including asymmetric setups when part families differ in size. Options such as live tooling, Y-axis, and servo tailstock transform the platform into a compact mill-turn solution capable of handling complex parts with fewer secondary operations. The externally mounted chucks and automation-friendly layout simplify setups, shorten changeovers, and allow direct robot integration without increasing required floor space.

Key Features

Available Models in the 2SI MKII Series

The Shimada-Kitako 2SI MKII Series provides the flexibility of multiple chuck sizes, live tooling options, Y-axis capability, and fully automated configurations. Whether your goal is higher throughput, reduced cycle time, or consolidation of multiple operations into one platform, Absolute Machine Tools can help configure a system that meets your production and automation goals.

Specifications

| Item / Model |

2SI-6

Request a Quote

|

2SI-8

Request a Quote

|

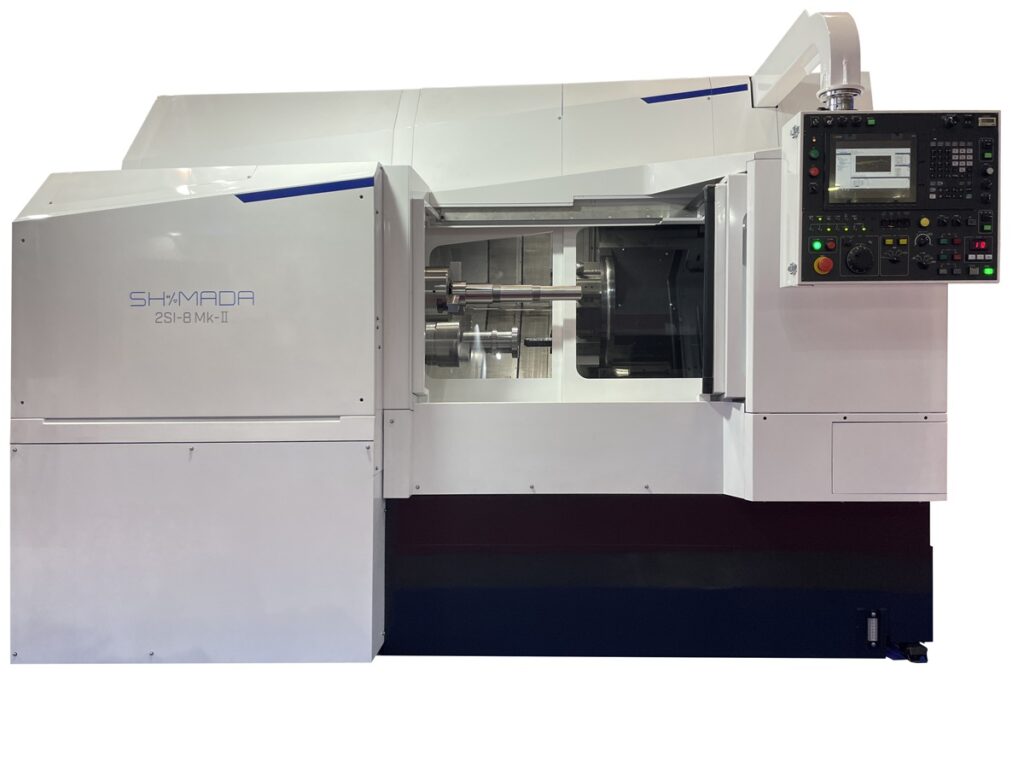

2SI-8 MK-II

Request a Quote

|

2SI-8 MK-II MY

Request a Quote

|

|---|---|---|---|---|

|

Swing Over Bed |

∅10.55″ (268 mm) |

∅10.55″ (268 mm) |

||

|

Max Machining Diameter |

∅7.09″ (180 mm) |

∅8.27″ (210 mm) |

∅9.65″ (245 mm) (10.55″ (268 mm) Conditionally) |

∅9.65″ (245 mm) (10.55″ (268 mm) Conditionally) |

|

Max Machining Length |

4.72″ (120 mm) |

4.72″ (120 mm) |

∅9.84″ (250 mm) |

∅9.84″ (250 mm) |

|

No. of Spindles |

2 |

2 |

2 |

2 |

|

Chuck Capacity |

6″ (152.4 mm) |

8″ (203.2 mm) |

8″ (203 mm) (10″ (254 mm) Conditionally) |

8″ (203 mm) (10″ (254 mm) Conditionally) |

|

Spindle RPM |

5,000 RPM |

3,500 RPM |

60 – 6,000 RPM |

60 – 6,000 RPM |

|

Motor |

(2) 5.5 / 7.5 kw |

(2) 5.5 / 7.5 kw |

(2) 15/18 kw Output |

4.0 kw Output 50.0 N • m Torque Rotary Tool Spindle Motor |

|

No of Tools / Turret Type |

8 Station (12 opt.) Gang Tool or Turret |

8 Station (12 opt.) Gang Tool or Turret |

10 Station Turret (12 opt.) |

10 Station Turret for Rotary Tools (12 opt.) |

|

O.D. Bite Shank Size |

∅0.984″ (25 mm) |

∅0.984″ (25 mm) |

||

|

I.D. Bite Shank Size |

∅1.57″ (40 mm) |

∅1.57″ (40 mm) |

||

|

Rotary Tool Spindle Speed |

6,000 RPM max. |

|||

|

X-Axis Travel |

4.72″ (120 mm) |

4.72″ (120 mm) |

7.28″ (185 mm) |

7.28″ (185 mm) |

|

Z-Axis Travel |

6.69″ (170 mm) |

6.69″ (170 mm) |

9.84″ (250 mm) |

9.84″ (250 mm) |

|

Y-Axis Travel |

+/- 25 mm |

|||

|

Rapid Feed Rate |

15 M/min. |

15 M/min. |

X: 30M/min. Z: 30M/min. |

Y: 21 M/min. |

|

Tailstock |

MT #4 Servo Drive |

MT #4 Servo Drive |

||

|

Tailstock Travel |

19.69″ (500 mm) |

19.69″ (500 mm) |

||

|

Spindle Centerline Height |

37.80″ (960 mm) |

37.80″ (960 mm) |

Machining Axis: 42.83″ (1088 mm) Detachable Axis: 50.11″ (1273 mm) |

Machining Axis: 42.83″ (1088 mm) Detachable Axis: 50.11″ (1273 mm) |

|

Machine Dimensions (LxWxH) |

74.80″ x 62.99″ x 70.87″ (1900 x 1600 x 1800 mm) |

74.80″ x 62.99″ x 70.87″ (1900 x 1600 x 1800 mm) |

98.43″ x 68.90″ x 70.87″ (2500 x 1750 x 1800 mm) |

98.43″ x 68.90″ x 70.87″ (2500 x 1750 x 1800 mm) |

|

Machine Weight |

7,937 lbs. (3600 kg) |

8,378 lbs. (3800 kg) |

14,330 lbs. (6500 kg) |

15,212 lbs. (6900 kg) |

Mk-Ⅱ×600-1024x949.jpg)

Mk-Ⅱ×600.jpg)